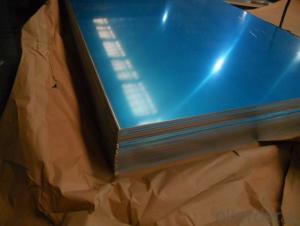

Aluminium Sheet Aluminium foil Factories in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 20 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Descriptions:

Aluminum sheet / plate

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration,

Auto radiator, Food container, Aluminum ceiling, Battery shell, LED Lighting, Kitchen rinse bath,

lamp shade , heat exchanger, nameplate, Power transformer, pallet etc.

CHEMICAL COMPOSITION

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

Product Information

Aluminum sheet is usually according to the following two points:

1. According to the alloy composition is divided into:

High purity aluminum plate rolling (by the content above 99.9 high purity aluminum)

Pure aluminum plate (ingredients made from pure aluminum rolling)

Alloy aluminum plate (composed of aluminum alloy and auxiliary, usually with aluminum and copper, aluminum and manganese, aluminum and silicon, aluminum magnesium, etc)

Composite aluminum plate or brazing plate (through a variety of means of material compound special use aluminum material)

Outside package aluminum (aluminum coated aluminum sheet used for special purposes)

2. According to the thickness is divided into: (mm)

Sheet (aluminum sheet) 0.15 to 2.0

Conventional plate (aluminum sheet) 2.0 to 6.0

Medium plate (aluminum plate), 6.0 to 25.0

Plate (aluminum plate) 25-200

Super thick plate more than 200

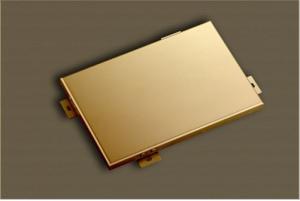

So far, the aluminum roofing sheets of all the metal walls has accounted for a dominant position in the metal walls, lightweight materials, reducing the load of the building, high-rise building provides a good selection conditions; waterproof, stain resistant, excellent corrosion resistance, the outer surface of the building to ensure the long lasting; processing, transportation, installation and construction are all relatively easy to implement, its widespread use to provide strong support; the diversity of colors can be combined and processed into different external shape, expanding the architect design space; high performance and low cost, easy maintenance, long life, meet the requirements of the owners. Thus, aluminum curtain wall construction as a form of high-impact, acclaimed.

Introduction surfaces and aluminum curtain wall performance comparison

Aluminum curtain wall surface material used in the following four kinds of (1) an aluminum composite panel (2) a single layer aluminum sheet (3) aluminum honeycomb (4) sandwich insulation aluminum, is currently using a large amount of the first three, since how kinds of surfaces to choose from, they are different before.

Aluminum curtain wall construction types and their advantages and disadvantages:

1. aluminum curtain walls in the form of structural units can be divided into aluminum curtain wall and aluminum curtain wall type member, the two forms, the so-called curtain wall unit refers to the panels, beams, columns assembled at the factory for the curtain wall unit in the form of curtain wall units in the field to complete the installation construction of a frame walls. The so-called curtain wall member is in the field followed by installation of columns, beams and panels frame curtain wall.

The problem aluminum roofing sheets, aluminum curtain wall application should pay attention to:

1. resistance to deformation of the curtain wall system

It must be carried out for each of the important parts of the curtain wall system of scientific mechanics calculations, considering wind pressure, weight, earthquake, temperature effect on the curtain wall system for embedded parts of the connection system, grid system, panels and fasteners careful school nuclear, to ensure the safety of the curtain wall.

2. Whether floating plate connection

Floating connector to ensure the ability to recover after deformation of the walls, to ensure the integrity of the walls, it does not make the walls due to the force caused by the deformation of the surface to avoid the walls bulging or sunken happening.

3. The fixation plate

Plate fixation plate flatness installation plays a decisive role. Discontinuity plates each fixed point agreement will result in deformation of the surface material affect the exterior effect, so the fixation plate must be given a fixed manner from compacted to ensure the flatness of the surface of the walls.

4. The composite material surfaces demolition edges if there is a reinforcing measures

because hemming composite panel material retaining only the positive plate thickness, thinner, lower intensity, so there must be a reliable measure of the reinforcing demolition edge.

5. The board is reasonable to set the back ribs to increase the strength and stiffness of the plate surface.

Strengthening arrangement distance ribs and rib strength and stiffness itself, we must meet the requirements to ensure the use of wall function and safety.

6. waterproof sealing method is reasonable

Waterproof seal many ways, structural waterproofing, waterproof inside, a plastic seal, seal different way prices are not the same, select the appropriate sealing method for the project, to ensure that the function and effect of the exterior curtain wall.

7. Selection of materials meets the norms, standards and design requirements.

- Q: Cast aluminum plate how to deal with a small hole

- Aluminum welding, you are there is a stomatal, welding process is not handled well. Strength certainly not reach, not to mention performance. There is no picture, look at the defect situation, I see can not remedy, think of ways to achieve its initial use of performance. Cast iron are recognized as difficult to weld it, this is a large cast iron machine arm after the fracture of the arm, the use of the scene, the accuracy of performance did not damage

- Q: Guiqiu, how can there be aluminum-plastic plate, ah, need to recover ah, please help Oh, thank you

- Looking for manufacturers

- Q: Dry hanging stone, aluminum-plastic board two kinds of external wall decoration use and maintenance costs, investment costs, the applicability of the two materials decorative effect construction speed

- Dry hanging stone, the use of aluminum-plastic plate is no standard, depends on your choice of materials. Maintenance costs should be different. The cost of investment is also to look at your material choices. Dry hanging stone for the building of the podium, the height is best not too high. Aluminum-plastic panels can be relatively high point, belonging to the modern style type.

- Q: Standard for aluminum-plastic plates

- And GB / T22412-2008 "ordinary decorative aluminum-plastic composite panels" for the inner wall panels and advertising boards, 4MM the following plates apply.

- Q: Is the polyethylene in the aluminum-plastic plate fireproof?

- Aluminum-plastic plate itself is not fire, because there is this plastic. Aluminum veneer is the true sense of the fire. (Timely processing of real problems, thank you!)

- Q: Want to know the building curtain wall, with aluminum veneer materials and aluminum-plastic plate material, what the pros and cons?

- More obvious differences: 1, cost; 2, hyperboloid operation; 3, construction efficiency; 4, process effects; 5, other such as color, Machinable size, on-site operations, material weather resistance and so on.

- Q: Aluminum plate is a plastic plate or metal plate

- Strictly speaking, aluminum-plastic panels and aluminum veneer are a kind of metal curtain wall material

- Q: What is the current market price of aluminum veneer and aluminum plate?

- Currently on the market price of aluminum-plastic plate, here only speak facade curtain wall, 200 yuan or so. Simple material prices.

- Q: I would like to ask where the fire aluminum plastic plate to sell ah?

- You can find Changzhou double European plate industry companies, fire rating can reach b1 level, product quality is good.

- Q: The status of aluminum - plastic plate products

- According to incomplete statistics, the existing aluminum-plastic composite panel enterprises more than 300, according to the national statistical caliber (all state-owned and annual sales income of more than 5 million yuan of non-state industrial enterprises) of aluminum-plastic composite panel manufacturing enterprises 204, Distribution in Guangdong, OKorder, Jiangsu, Zhejiang, Shandong, Jiangxi and other places, employing about 45,000 people, of which non-state-owned enterprises have more than 80%. 2008 industry-wide profits of about 1.8 billion, annual sales of nearly 20 billion yuan. 2008 aluminum-plastic plate production 220 million square meters, ranking first in the world, accounting for more than 80% of the world's total output. China is the world's largest producer of aluminum-plastic composite panels, consumers and exporters, and some of the enterprise's product quality has reached or exceeded the level of advanced countries.

Send your message to us

Aluminium Sheet Aluminium foil Factories in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 20 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords