Alkali Resistant Fiberglass Mesh Cloth for Marble Mesh Buildings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alkali Resistant Fiberglass Marble Mesh for Buildings

Definition of Fiberglass Mesh Fabric

Fiberglass Marble Mesh is mainly alkali-resistant fiberglass fabric. Fiberglass Mesh mainly use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. Fiberglass Mesh is an ideal engineering material in construction and decoration industry.

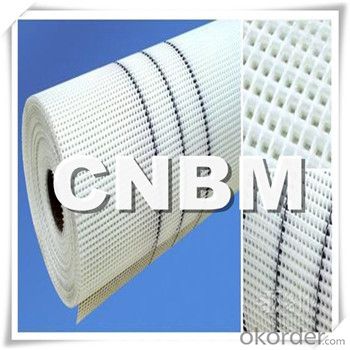

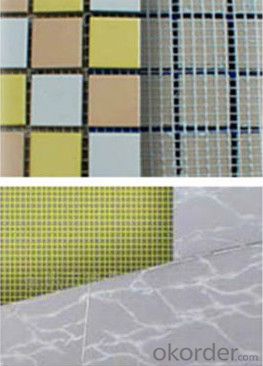

Image of Fiberglass Marble Mesh

Application/Usage of Fiberglass Marble Mesh

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement Fiberglass Mesh, Electrical heating mats Fiberglass Mesh

Marble slab reinforcement / Mosaic carrier Fiberglass Mesh, Asphalt reinforcement (roof water-proof) Reinforced lightweight construction boards Fiberglass Mesh.

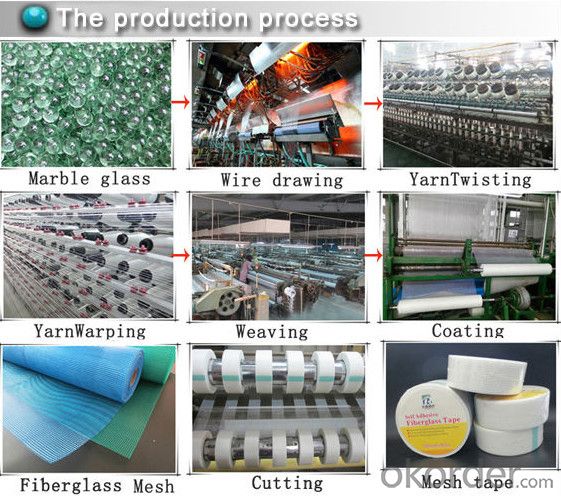

Fiberglass Marble Mesh Production Process

Application :

Package: Fiberglass Marble Mesh are packed in shrink-wrapped, then put into cartons or pallets.

Packing volumes: about 20000m/20FCP, 40000m2/40HQ.

Delivery: About 15 days after confirming the order.

FAD:

Q: What is the storage of Fiberglass Mesh?

Store Fiberglass Mesh out of direct sunlight, away from direct contact ground or concrete;

Store Fiberglass Mesh rolls in cool, dry location, away from weather or other damage.

Q: What is the guarantee period of Fiberglass Mesh ?

Fiberglass Mesh: Four years under normal weather conditions and usage directions.

Q: What is the Advantage of Fiberglass Mesh ?

Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

Good dimensional stability & positioning property, stiffness, smoothness an difficult to shrink & deformation.

Good impact resistance and not easy to be teared.

Q: Why choose our CNBM Fiberglass Mesh?

We are the manufacturer of Fiberglass Mesh, price will be reasonable and much competitive

We have produced Fiberglass Mesh strictly in according to customers' detailed requirements

CNBM Fiberglass Mesh theme is: Good Quality, High Credibility & Best Service.

- Q: How do you paste the mesh cloth on the back of the stone?

- This is only for those of the plate (plate - not for the world) and cut out of the finished product, there is no side treatment.

- Q: What's the use of fiberglass mesh?

- Main performance and characteristics:1 、 good chemical stability. Alkali resistance, acid resistance, water resistance, cement corrosion resistance, and resistance to other chemical corrosion; and resin adhesion, soluble in styrene and so on.2, high strength, high modulus, light weight.3, good dimensional stability, stiffness and smooth, not easy to deformation, shrinkage of.4 、 good shock resistance. (because of high mesh strength and good toughness)5, mildew change, pest control.6. Fire protection, heat preservation, sound insulation and insulation.

- Q: The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- The building often causes the perineum to warm up and contract cold and cause cracks. Reduce the service life, glass fiber mesh cloth can be the maximum restraint to reduce such adverse effects. The glass fiber mesh cloth is insulated and used in the outer part of the main structure so as to save indoor space. It is effective enough for indoor use

- Q: Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q: What is the function of the wall cloth mesh?

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q: What harm does fiberglass mesh have to people?

- Inhalation of respiratory tract causing lung damage. Three

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

Send your message to us

Alkali Resistant Fiberglass Mesh Cloth for Marble Mesh Buildings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords