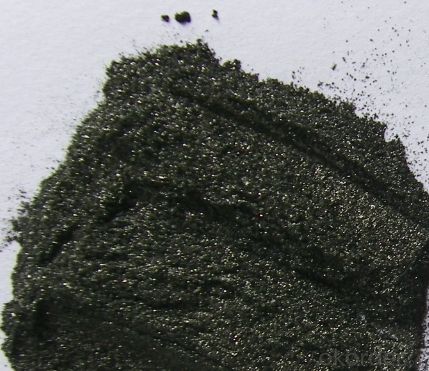

8B Natural Flake Graphite NFG - Shandong Province Refractory Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Natural Flake Graphite:

1.Perfect crystallization, great size in flake, high density

2.Low content of mica,high luminance

3.Excellent properties

Advantage of Natural Flake Graphite:

Perfect crystallization, great size in flake, high density, low content of mica, high luminance, excellent physical properties, such as resistance to high temperature, electric and thermal conductivity, self lubricity, and superior chemical stability

Size of Natural Flake Graphite:

Adjustable to meet customer requirements, and major sizes include 50, 80,100, 120,150,200,325 mesh

Packing:

Provide various packing options according to customer requirements. Including Woven Bags, Paper Bags and Plastic Bags of 25KG, 50 KG, and 1000KG.

| Article | Specification | Particle Size(%) | Fixed Carbon | Moisture | |

| Screen Oversize | Screen Undersize | (%) | (%) | ||

| High Carbon | 32Mesh | ≥80 | 94-99 | ≤0.5 | |

| Graphite | 50Mesh | ||||

| 80Mesh | |||||

| 100Mesh | |||||

| 150Mesh | |||||

| -100Mesh | ≥80 | ||||

| -200Mesh | |||||

| -300mesh | |||||

| -500Mesh | |||||

-1000Mesh -5000mesh | |||||

| Intermediate Carbon | 32Mesh | ≥80 | 80-93 | ≤0.5 | |

| Graphite | 50Mesh | ||||

| 80Mesh | |||||

| 100Mesh | |||||

| 150Mesh | |||||

-100Mesh -1000mesh -5000mesh | ≥80 | ||||

- Q: It's hard to remove a lot of graphite powder on the glass cake. Who has a good way to remove the graphite powder above?

- Suggestion: use a certain amount of concentrated nitric acid infiltrated graphite part, nitrate solution the best there is a certain amount of 1-2 weeks (timing can also be placed with a glass rod, pour stirred) acid, diluted with water to acid and then scrub brush. Because the temperature nitric acid reaction is very slow, but the long-term infiltration, the graphite surface. Especially with the glass contact surfaces may be immersed in a small amount of acid, oxidation, then scrub may have the effect.

- Q: Are sand and particle powders used for casting quartz sand? Detailed and accurate.

- General small foundry is river sand, quartz sand is also useful. But the cost is higher, if the product is not high, the river sand on it. You have a particle powder quartz powder with clay, coal powder, in what way do you use.

- Q: Can graphite powder be used in lithium batteries?

- Qingdao Huatai graphite more than 20 years experience in the production of graphite powder to tell you that graphite powder can be used in lithium batteries.

- Q: Method for identifying iron powder, aluminium powder and graphite powder

- They can be used to determine the reaction with acid: the same quality, the same mass fraction of dilute hydrochloric acid solution, and then the three kinds of powder into three kinds of solution, graphite powder and hydrochloric acid reaction observed, iron and aluminum powder and hydrochloric acid hydrochloric acid reaction is slow, can react violently, prove that the nature of the most active aluminum iron, the main component of carbon graphite is the most stable chemical properties.

- Q: What effect does graphite powder and graphite gas have on people? Also, I smell graphite gas as if I can't breathe. What's the harm to people?

- Graphite powder itself is harmless, and even eat nothing, you smell the so-called graphite powder can only be said to be in (high temperature) such as copper and aluminum smelting gas produced by graphite powder, graphite powder for sulfur, after high temperature will have a S taste great, as far as possible to avoid a long time.

- Q: Antistatic concrete with graphite powder and conductive carbon black, which effect is good?More specific. I don't quite understand

- But the conductive carbon black in plastic system can achieve better quality with less graphite is because in polymer systems, factors of conducting conductivity in addition to the conductive powder itself, but also with the distribution of conductive particles in the polymer related. The same quality of the carbon black and graphite carbon black, due to a smaller proportion, occupy a large volume fraction of the polymer, is conducive to the formation of conductive network, which was better than the effect of conductive filler graphite.But in the high aggregation state, the conductivity of graphite aggregate is much better than that of carbon black. The good conductive electrode material is made of graphite instead of carbon black.

- Q: Know how the colloidal graphite powder comes in

- Smaller graphite particles are uniformly dispersed in water, oil, and other organic solvents, forming a black, sticky suspension. Also called colloidal graphite or graphite milk.Colloidal graphite was first obtained in nineteenth Century by Acheson. The raw material is natural graphite or artificial graphite.

- Q: Why does an electromagnetic point timer not prick a needle and use toner paper?

- With the needle point than the powder paper friction, many experimental results of!

- Q: How can the antirust graphite powder used for locks be operated? Where is it painted?

- In the process of switching the door locks on weekdays, the best holding handle lock tongue into the lock, closed the door and then let go, don't bang the door, otherwise it will reduce the service life. Do not use wet cloth to wipe the lock and handle, because some metallic lock will rust; lock alloy material will lose coating worn, beautiful appearance.

- Q: Refractive index and absorbance of graphite powder

- I have already said, the color change, that change the material inside, you have not had the measured absorbance of the substance determination in you have set the wavelength of the sum of the original material, but a new generation of absorption material and the residual absorbance. The original substance must have been reduced, and its contribution to absorbance is correspondingly reduced, but the newly formed material may have a stronger absorption at this wavelength, so the overall result is an increase in absorbance. If you want to use absorbance analysis, you must select a suitable wavelength so that only the material you wish to measure at this wavelength is absorbed without interference from other substances.

Send your message to us

8B Natural Flake Graphite NFG - Shandong Province Refractory Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords