Raw Materials for Refractory:87% Shaft Kiln Calcined Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

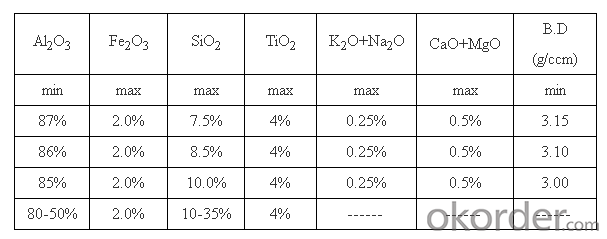

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Powder | Material: | Raw Bauxite |

| SiO2 Content (%): | 7.5%-35% | Al2O3 Content (%): | Al203:85%,86%87% | Model Number: | ZYD1511 |

| Brand Name: | cnbm | color: | pale yellow and dark grey | CaO+MgO: | 0.5Max |

| size: | natural lamp, 0-100/0-50/0-25 mm;0-1/1-3/5-8 mm | B.D.(g/ccm): | 3.10-3.15 | TIO2: | 4%MAX |

| FE2O3: | 2%MAX |

Packaging & Delivery

| Packaging Details: | IN BULK 1.25MT BIG BAG OR BY BUYERS REQUIREMENT |

| Delivery Detail: | 15-20DAYS |

Shaft Kiln Kalcined Bauxite

Product Description

Factory overviews

Laboratory

Packaging & Shipping

Our services

Give an answer within 24 hours;

Offer competitive prices;

Provide various certificates according to client’s requirements;

Provide sample freely;

If needed, we are able to travel with customer to visit our factories;

Satisfy the client’s needs to the maximum.

Advantages

We are an experienced Bauxite manufacturer with a decades-year long history;

The majority of our material are from Shanxi, a place known as the home of bauxite, so we are sure that the quality of product we supplied is very high;

We have both advanced machine and skilled workers in our factory;

In the term of material transportation, we have the professional export team;

What is worth mentioning is that we enjoy a good reputation around the world and we have many regular customers every year.

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- Each country has its own fire safety standards, I do not know which country's standard do you want to know, and each country of fireproof material to the division level is not the same. GB GB 8624, the German standard DIN 4102-1, the British standard BS 476, French standard NF P92 -501 and so on. GB 8624 is Chinese building materials and grade of combustion performance. The information coming form fire resources network (FireTC.

- Q: What is molten silicon? What refractoriness do refractories made by it have? What properties of using does it have?

- Molten silicon can be called quartz glass, which shows an amorphous silicon state. It is a liquid fusion at above 1723 degree and is an ultra-cooling state at low temperatures. It is not generated in refractories, but generated in the matrix, showing liquid state at a high temperature capable of buffering the stress with somewhat binding properties. If quartz glass is used as refractory, its function are melrly these ones. (These are what I konw for reference only.)

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Grade of fireproofing material: Class A: Incombustible building material, almost without burning. class A1: Non-combustible, no open flame,class A2: Non-combustible,it needs to measure smoke and be qualified. Class B1: Nonflammable building material: Nonflammable materials have good flame resistance function. when it contacts open fire or is under high temperature, it's difficult to burn and be spreading rapidly, and will stop burn after removing the combustion?source. Class B2: Combustible?building?materials: Combustible materials have good flame resistance function. when it contacts open fire or is put in the air at high temperature, it will immediately burst into flames, and easily result in the spreading of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. Class B3: Inflammability building materials, without any flame resisting effects, easy to burn, and has large danger of fire disaster.

- Q: What high-molecular polymers can be used as fire-resistant material binder?

- Organic silicon

- Q: I wanna ask what are the acidic refractories?

- (1) silica?brick with stronge acidity, unshaped silicious refractory, quartz glass and fused silica combined products; (2) semi-silica refractory with moderate acidity and pyrophyllite refractory; (3) clay-based refractory with weak acidity.

- Q: How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Generally how can do high-temperature performance to measure how much liquid may affect hot bending strength rul refractoriness levels of high temperature creep?

- Q: How many grades of fire?rating are there for interior decoration materials?

- It can be divided into structural material and base?material based on materials. It can also be divided into flammable, flame retardant and non-combustible materials based on fireproof types. There is no fire?rating for materials. But lengths of time of flammability limits are different.

- Q: What are the commonly used admixture for alumina-magnesia refractory? What are the impacts on its performance?

- 2, form Mg-SiO2 coagulation and combination, CA cement bond? Bricks can generally be made by combing with phenolic resin, castable use 1, combined with silicon powder; 3, can also combined with brine MgCl is binding agent

- Q: what materials can make external wall fireproofing paint have the fireproofing effect

- Fire retardant coatings are generally used for fireproofing and fire?retardant of steel structure buildings, large stadiums, railway stations, thermal power station, nuclear power plants, urban tunnels, large-scale industrial plants, warehouses, flammable material surface. Improve the refractory time of buildings and combustible materials.

Send your message to us

Raw Materials for Refractory:87% Shaft Kiln Calcined Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords