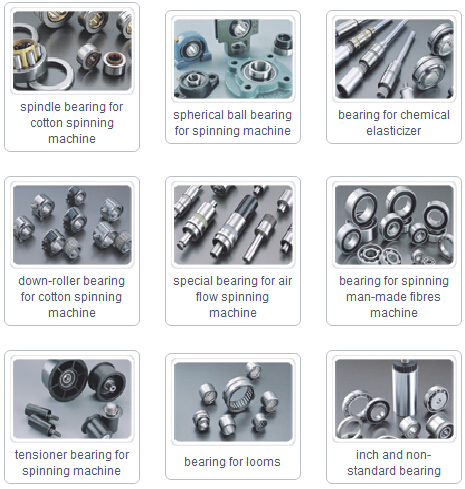

Textile Machinery bearings Textile bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Textile Machinery bearings:

Bearings for textile machinery are generally used under severe working conditions that require long service life, heavy loading capacity, high rotation speed, low noise , and stable operations, the bearings for textile machinery independently developed by CNBM have excellent performance and have already been adopted by mainly domestic manufactures of textile machines. Special bearings manufactured by CNBM for airflow textile machines can run steadily at a very high speed with small amplitude, low noise, and long service life. Top roller bearings for textile machines have the characteristics of strong self-aligning function, supreme dust-proof performance, heavy loading capacity, stable operation, and long service life.

- Q: What are the differences between angular contact bearings and deep groove ball bearings?

- You take a look at two, you know, the angle of contact with a few angles to look at, you know the difference

- Q: What is angular contact ball bearing contact angle?

- The angle between the imaginary line of the contact between the roll and the raceway and the vertical line of the axis of rotation

- Q: What is the difference between deep groove ball bearings and angular contact ball bearings?

- The above two said performance, actually because the contact angle is different, the original contact angle of deep groove ball bearing is 0 degrees. Contact angle of angular contact is greater than 0 degrees, generally 15 degrees. 25 degrees. 40 degrees. Thrust angle contact bearings greater than 45 degrees.The consequences of angular contact, as above two said.

- Q: Angular contact ball bearings, how to judge the size of the mouth?

- Angular contact bearing on both sides of the outer ring thickness is not the same thin, over there is big mouth

- Q: The difference between ultra high speed angular contact ball bearings and other plain bearings

- The ability to bear the axial force of angular contact ball bearings than ordinary high speed ball bearings, angular contact ball bearing is slightly lower than the ordinary ball bearings of the same type.

- Q: What are the reasons for the use of tapered roller bearings and angular contact ball bearings?

- Bearing capacity and the form of motion and load factors are different, the choice of bearings compatibility is determined by theory and practice. Visual interpretation is the role of the two bearings, see the mechanical design manual - bearing chapter

- Q: Two angular contact ball bearings, the use of clearance problems

- No adjustment required,DB: back to backDF: face to faceDT: series connectionSU: single arbitrary combinationDU: any combination of two bearings.

- Q: How many angles are there in angular contact ball bearings? How many degrees are they?

- A stands for 30 degrees, A5 stands for 25 degrees, B stands for 40 degrees, and C stands for 15 degreesThe new Seiko NSK serves you!

- Q: How can angular contact be distinguished from the front and back? What are the characteristics of each?

- The front outer ring is wide and the outer back is narrow.

- Q: Do angular contact ball bearings come with a sealing cap?

- Without a sealing cap

Send your message to us

Textile Machinery bearings Textile bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords