7 Tons Diesel Powered Forklift product CPC70F

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forklift Description:

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Forklifts are a critical element of warehouses and distribution centers. It’s imperative that these structures be designed to accommodate their efficient and safe movement. In the case of Drive-In/Drive-Thru Racking, a forklift needs to travel inside a storage bay that is multiple pallet positions deep to place or retrieve a pallet. Often, forklift drivers are guided into the bay through guide rails on the floor and the pallet is placed on cantilevered arms or rails. These maneuvers require well-trained operators. Since every pallet requires the truck to enter the storage structure, damage is more common than with other types of storage. In designing a drive-in system, dimensions of the fork truck, including overall width and mast width, must be carefully considered.

A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations. In 2013 alone the top 20 manufacturers worldwide posted sales of $30.4 billion with 944,405 machines sold.;and the U.S. forklift market was nearly $33 billion.

Health care providers should not recommend that workers who drive or use heavy equipment such as forklifts treat chronic or acute pain with opioids. Workplaces which manage workers who perform safety-sensitive operations should assign workers to less sensitive duties for so long as those workers are treated by their physician with opioids]

Forklift training in the United Kingdom

In the UK, the Provision and Use of Work Equipment Regulations state that operators of fork lift trucks must be adequately trained, the general standards of that training and good operating practice are found in the HSE Code of Practice 117 (Third edition) issued in 2013. Third party organisations have developed de facto 'best practice' standards for forklift training, commonly referred to in the UK as a 'forklift licence',(theses are no longer recognised as proof of training as defined in the COP 117 (third edition) and as such training is not a legal requirement as is commonly believed.Organised training however helps to demonstrate that an employer has taken steps to ensure its 'duty of care' in the unfortunate event of an accident.

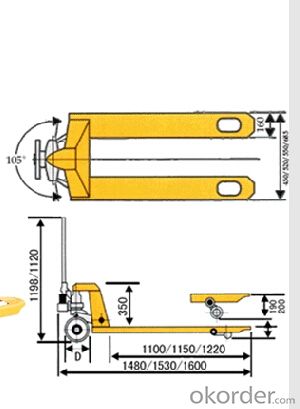

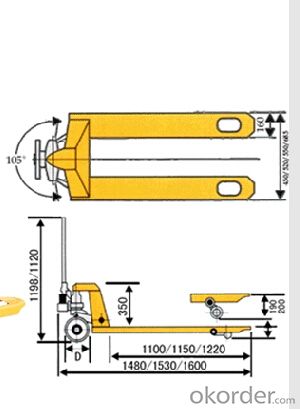

Forklift Specification:

Model | CPCD70F | |

Load capacity kg | 7000 | |

Load center mm | 500 | |

Power type | diesel | |

Max.lifting speeds(with load)mm/s | 320 | |

Max.Driving speeds(with without load)km/h | 26/30 | |

Max.Towing (with load)kN | 52 | |

Gradeability(with/without load)% | 25/20 | |

Lifting height mm | 3000 | |

Tilting angles(forward-backward)° | 6/12 | |

Free lift mm | 210 | |

Min. turning radius mm | 3250 | |

Min. right angle alsle width mm | 3090 | |

Min. under-clearance mm | 230 | |

Dimensions | A Overall length (inincluding fork) mm | 4800 |

B Overall width mm | 1995 | |

H Overall height(mast lowered) mm | 2500 | |

H2 Overall height(mast extend) mm | 4420 | |

H3 Overall height to overhead guard mm | 2420 | |

A1 Fork overhang mm | 632 | |

A2 Wheel base mm | 2250 | |

Tread | B1 Front tread mm | 8.25-15-14 |

B2 Rear tread mm | 8.25-15-14 | |

Tyre | Front tyre | 1470 |

Rear tyre | 1700 | |

Total weight kg | 9500 | |

B3 Fork width mm | 150 | |

H4 Fork thickness mm | 65 | |

Backrest height mm | 1365 | |

A3 Fork length mm | 1200 | |

Engine | Engine model |

|

Rate power KW | 80.9 | |

Rotate Speed At Rate Power rpm | 2500 | |

Max.torque Nm | 353 | |

Rotate speed at max torque rpm | 1650 | |

Operating pressure | 2-12/80AH | |

Type of power shift | Hydraulic | |

Forklift Images:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: Can a forklift drive into an elevator?

- My friend, although it has happened, I still want to tell you that it's ok if you do the right thing. I don't believe that will be difficult for you. Remember to study forklift and elevator operation mode. This way, you have the bottom, more the next time convenient express

- Q: How to test a forklift

- There are many places on the Internet where you can check your forklift.

- Q: Why do you lean forward when you're driving with a forklift?

- Safety first, goods fork no-load and load should be and not forward. Is for the sake of safety, not for the convenience of work. If you forward or parallel cargo in front of someone, to brake, your shipment is not fly? Pour is to make the goods more stable, form a kind of resistance. Remember!

- Q: For what occasion is a forklift solid tire and pneumatic tyre

- First forklift is no shock, not like a car has good shock absorption measures, completely on seat to buffer, inflatable tires that can reduce the vibration of the body, to a certain extent in more bumpy road runs not so uncomfortable. However, the fact that the heart is in a foreign country is a lot more on the road that is flat, not applicable to the place that is very bumpy.

- Q: Do forklifts need to be measured?

- Trade settlement, security protection, health care, environmental monitoring, your forklift belongs to which category, if it does not belong to do not check. Consult the local quality supervision bureau.

- Q: Is it dangerous to drive a forklift?

- Somebody must be shorter than we in the world, than we are stupid, than we are ugly, than we don't have the talent, has created a miracle finished our distant dream. The deaf can be the only one like creation, the blind can break the high jump record, no hand can play the piano to do talent, no hands no feet can become a speaker, legs residue can be Olympic champion... Why is that? It shows that success is never a classic! One, he was desperate; He never complains; Three, he has no limits in his life The forklift is not only about speed, but also about the accuracy of the Angle, which can easily cause a safety accident.

- Q: How do you change the oil of the forklift truck, without a slot and a jack, so you can change it on the ground? Do you know a teacher?

- You can do it long enough to get the wheel on the board so you can get into it

- Q: What are the requirements for a forklift

- To apply for a job: Older than 18 years of age; A healthy body Have certain level of culture and work experience; Knowledge and skills in the safety and technology of the special equipment operators with forklift license;

- Q: Where to test for a forklift?

- The forklift card is the certificate issued by the bureau of quality supervision, which is usually a month to two months.

- Q: What is the meaning of a forklift?

- LNG is short for liquefied natural gas, mainly methane. LNG is colorless, odorless, non-toxic and non-corrosive, its volume is about 1/600 of the volume of gaseous natural gas, and the weight of LNG is only about 45% of the water in the same body. LNG forklift is a forklift truck with liquefied natural gas. The advantages of the LNG fork lift, the energy saving effect, are obvious, because of the rising price of oil, the fuel cost of the forklift truck is 20% ~ 35%. (details in the local oil and gas price difference) 2 belongs to clean energy, natural gas, gas forklift truck emissions is far better than wood, gasoline forklift, CO emissions decreased by 90%, 75% less HC, NOx reduce more than 35%. There are no black smoke problems like diesel forklifts. It protects the employees' health and prevents the products from being damaged. 3, good dynamic performance, the technology design of automotive electronic control system (ECU), the output of the engine power and torque than the same model of the diesel engine has been increased 5% ~ 5%. The engine lives longer. Gasification improves the engine's performance and improves the lubrication of the engine. More than twice the life of a diesel engine. Can save more than 30% for the customer. 5, using gas wood can greatly slow down area, the status of the gasoline shortage of peak, to diversify energy use, avoid the wood, and gasoline shortages affect enterprise production

Send your message to us

7 Tons Diesel Powered Forklift product CPC70F

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords