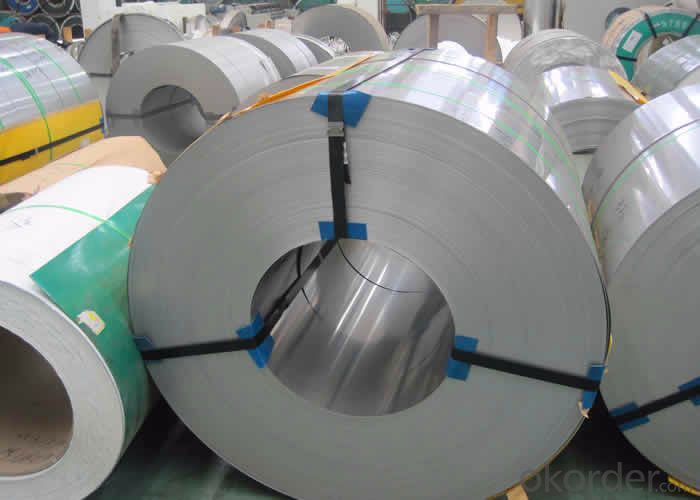

430 SERIOUS COLD ROLLED STAINLESS STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | 400 series | Thickness: | 0.25-2.0mm |

| Place of Origin: | Guangdong China (Mainland) | Brand Name: | CMAX | Model Number: | SUS430 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA, HL, NO.4 |

| Application: | Utensils, kitchenware, cutlery, pots & bowls, sinks, gas stove etc. | Width: | 800-1300mm | Length: | As requested |

| Market: | Asia, Mid East, South America etc. | Form available: | coil/ panel/ strip/ sheet | Sample: | Available |

| Packing: | PVC film with wooden pallet | Hardness: | From full hard to DDQ | Edge: | Mill edge/ Slitting edge |

| Feature: | Clean & corrosion resistance | Cr content: | 16%-18% | Steel type: | Ferrite stainless steel |

| Product name: | Cheap Cold Rolled Stainless Steel Coil 430 |

Packaging & Delivery

| Packaging Detail: | Standard export package, pvc film with wooden pallet. |

| Delivery Detail: | 15-30 days after receiving deposit |

Specifications

Cheap cold rolled stainless steel coil 430

Manufacturer

Origin: Baosteel, Tisco, Jisco

High technology & advanced equipment

Product Description

Cheap Cold Rolled Stainless Steel Coil 430 / ss430

| Item name | Cheap Cold Rolled Stainless Steel Coil 430 |

| Grade | 400 series |

| Type | Steel coil |

| Origin | CHINA |

| Standard | AISI,ASTM,DIN,GB,JIS |

| Thickness | 0.25mm-2.0mm |

| Width | 800-1300mm |

| Length | As requested |

| Surface treatment | BA, 2B, HL, No.4 |

| Edge | Mill edge/ slitting edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, cutlery, pots & bowls, sinks, food industry, construction decorations etc. |

| Package | Standard export package, PVC film with wooden pallet |

| Payment terms | T/T, 20% deposit in advance, balance against copy of B/L |

| Delivery time | 15-30 days after receiving the deposit |

- Q: How do stainless steel strips perform in high-pressure steam?

- Known for their excellent performance in high-pressure steam environments, stainless steel strips have inherent resistance to corrosion and high-temperature strength, enabling them to withstand the harsh conditions associated with high-pressure steam applications. The presence of chromium in stainless steel forms a protective layer that prevents oxidation and maintains the material's integrity even at elevated temperatures. Moreover, stainless steel strips demonstrate low thermal expansion and possess remarkable mechanical properties, making them suitable for high-pressure steam systems. In conclusion, stainless steel strips guarantee the safety and efficiency of steam applications, as they are highly reliable and perform exceptionally well in high-pressure steam environments.

- Q: 301 stainless steel belt and 304 stainless steel belt, which quality is good?

- You can be responsible to tell you, 304 to better stainless steel, the amount of nickel will be on the 304 to more than 301

- Q: Are stainless steel strips suitable for architectural mesh?

- Yes, stainless steel strips are suitable for architectural mesh. Stainless steel is a popular choice for architectural applications due to its durability, strength, and corrosion resistance. Stainless steel strips can be formed into various patterns and designs, making them ideal for creating decorative and functional architectural mesh. Additionally, stainless steel is low maintenance and can withstand harsh environmental conditions, making it a reliable choice for long-lasting architectural installations.

- Q: What is the impact toughness after cryogenic treatment of stainless steel strips?

- The impact toughness of stainless steel strips is generally improved after cryogenic treatment. Cryogenic treatment involves subjecting the steel to extremely low temperatures, typically around -196°C (-321°F), to enhance its mechanical properties. This process causes a transformation of the steel's microstructure, resulting in increased hardness, strength, and resistance to wear. The impact toughness of a material refers to its ability to absorb energy and resist fracture under high-stress conditions. Cryogenic treatment helps to refine the microstructure of stainless steel, reducing the presence of brittle phases and improving its resistance to cracking or fracture when subjected to impact or high-stress situations. The low-temperature treatment also reduces residual stresses in the steel, which can further enhance its impact toughness. The reduction in residual stresses helps to improve the steel's ductility, making it less prone to sudden failure or fracture under impact or high-stress loads. Overall, the cryogenic treatment of stainless steel strips enhances their impact toughness, making them more suitable for applications that require high durability, resistance to cracking, and improved performance under impact or high-stress conditions.

- Q: Can stainless steel strips be cut or shaped?

- Indeed, it is feasible to cut or shape stainless steel strips. Renowned for its resilience and adaptability, stainless steel can be manipulated and sculpted into a multitude of configurations. There exist diverse approaches for cutting stainless steel strips, including shearing, sawing, or the employment of laser cutting. Similarly, shaping stainless steel strips can be accomplished via methods such as bending, rolling, or forming. Consequently, these techniques facilitate the customization of stainless steel strips to fulfill distinct design or functional necessities across various sectors, encompassing construction, automotive, and manufacturing.

- Q: Are stainless steel strips suitable for conveyor systems?

- Yes, stainless steel strips are suitable for conveyor systems. Stainless steel is durable, corrosion-resistant, and can withstand high temperatures, making it an excellent choice for conveyor systems that require strength and reliability. Additionally, stainless steel strips are easy to clean, maintain, and offer a smooth surface for efficient material handling.

- Q: Can stainless steel strips be used in the production of medical implants?

- Yes, stainless steel strips can be used in the production of medical implants. Stainless steel is a commonly used material in the medical field due to its excellent corrosion resistance, strength, and biocompatibility. It is often used for surgical implants such as bone plates, screws, and dental implants. Stainless steel strips can be formed, cut, and shaped into various implant components, providing the necessary strength and durability required for medical applications. Additionally, stainless steel is easy to sterilize, making it suitable for use in medical implants where cleanliness and hygiene are crucial.

- Q: Can stainless steel strips be used in the production of aerospace components?

- Yes, stainless steel strips can be used in the production of aerospace components. Stainless steel is widely used in the aerospace industry due to its excellent properties such as high strength, corrosion resistance, and heat resistance. These properties make stainless steel strips suitable for various aerospace applications, including the manufacturing of structural components, fasteners, and fittings. Additionally, stainless steel's ability to withstand extreme temperatures and exposure to harsh environments makes it a reliable material for aerospace components.

- Q: What is the minimum thickness available for stainless steel strips?

- The minimum thickness available for stainless steel strips typically varies depending on the specific manufacturer or supplier. However, it is common to find stainless steel strips with a minimum thickness ranging from 0.001 inches (0.0254 mm) to 0.020 inches (0.508 mm).

- Q: Are stainless steel strips suitable for electrical applications?

- Indeed, electrical applications find stainless steel strips to be a fitting choice. As a remarkably adaptable substance, stainless steel not only boasts exceptional resistance against corrosion but also showcases durability and excellent electrical conductivity. Consequently, it proves to be an ideal option for an array of electrical uses, encompassing electrical enclosures, conduits, electrical connectors, and grounding equipment. Moreover, stainless steel strips demonstrate the ability to endure elevated temperatures, rendering them appropriate for heat-related applications like electric heating elements. In summary, stainless steel strips present a dependable and enduring resolution for electrical applications.

Send your message to us

430 SERIOUS COLD ROLLED STAINLESS STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords