35 Color Strip Extuder with High Speed and Steady Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

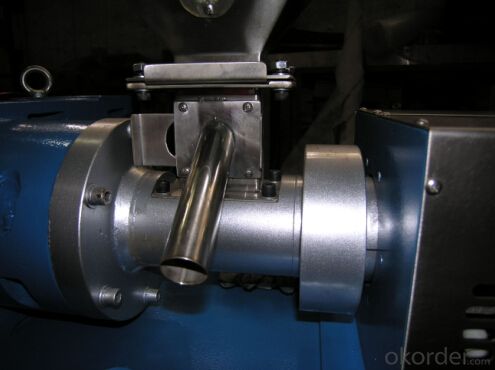

Φ35 Color Strip Extruder Horizontal and lifting type

1. Main use of 35 Color Strip Extruder

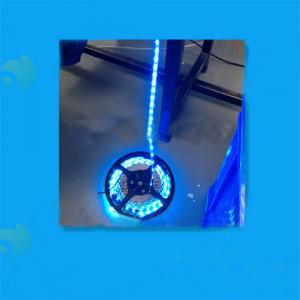

It is mainly used for producing double color strips or strips extruding.

2. Major Configuration of 35 Extruder main machine and performance

2.1 Temperature control is much precise; the temperature down is controlled by 2 windmills;

2.2 Feeding way: This hopper’s material is made of Stainless steel, rotation type feeding way;

2.3 Bearing of whole machine: imported brand;

2.4 Moving way of device: 4 casters is installed below the machine, it is very convenient to move;

3. Main technical specification of 35 Color Strip Extruder

3.1 Extruding capacity: 18kg/h in total

PVC: Max18 kg/h

PE: Max12 kg/h

3.2 Condition: New Application:

3.3 35 Color Strip Extruder Plastic Processed: PE,PVC,PP

3.4 Screw Design: Single-screw

3.5 Automatic Grade: automatic

3.6 Place of Origin: Shanghai China (Mainland)

3.7 Brand Name: CNBM

3.8 Model Number: SJ-35

3.9 Voltage: 380V 50HZ

3.10 Certification: CE After-sales

3.11 Service Provided: Engineers available to service machinery

3.12 Overseas material: PE/ps/ABS/PP

3.13 Plastic extruder: double screw/single screw

3.14 PLC: Simens

3.15 Transportation: by sea or by train

3.16 Continuity produce: yes

3.17 Automatic: yes electric

3.18 Parts: selects famous brand

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

- Q: Extrusion blow molding machine, storage or continuous type good?

- This is not good or bad, depends on what your product is If the product cycle large volume high capacity is bound to produce a product with storage because of your long,

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip two: choose topics based on your interests. The title selection and refining skills of the two, is from the author's hobbies and interests, only conform to the topics and interests, the author accumulated data can work normally, language applications can also Practice makes perfect.

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- Fan, water pump at low speed, torque is not enough, resulting in high current, if vector control can be ideal.

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

35 Color Strip Extuder with High Speed and Steady Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 40 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords