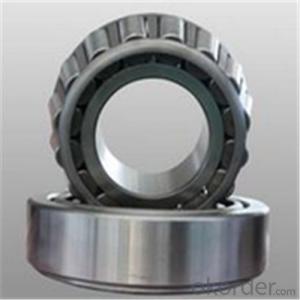

30230 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: What is the size of tapered roller bearings 352214?

- Bearing type: tapered roller bearingNew model: 352214Old model: 97514EInternal diameter (mm):70Outside diameter (mm):125Width (mm):75

- Q: What are the conditions for the normal and reverse loading of tapered roller bearings?

- Hello, I'm Camry KMR bearingsTapered roller bearings are generally used in pairs, according to the adjustment, installation and use of different occasions, there are two following arrangement. The 1. suits (outer ring relatively narrow end) corner contact ball bearing or tapered roller bearing pressure center distance is less than two bearing mid span, called dress. The shafting of this method is simple in structure, easy to assemble, disassemble and adjust, but the heating elongation of the shaft will reduce the axial clearance of the bearing and even die.

- Q: Is the tapered roller bearing so correct?

- Tapered roller bearings are designed for the inner ring, outer ring raceway and roller cone vertex on the central axis of the bearing, radial load acting on the bearing, axial force is generated. Therefore, it is necessary to use the 2 bearings for use, or as double pairs of bearings, double row bearings. Combination and double row tapered roller bearings, when radial loads act on tapered roller bearings

- Q: What are the E and Y values of the 30209 bearings of tapered roller bearings?

- The shoulder of the positioning shaft is positioned; the transition shaft shoulder is provided for the disassembly of the parts on the shaft or the prevention of the stress concentration. But the axial shoulder will inevitably increase the diameter of the shaft, and the shoulder of the axle will change due to the stress concentration.

- Q: How does the roller of tapered roller bearings fit in?

- Tapered roller bearings are made up of outer rings, inner rings, rollers, and cages. The outer ring is a single body, and the inner ring, roller and cage are assembled together. They are called inner components. Tapered roller bearings belong to separable bearings, and when installed, the two components (inner and outer rings) can be fitted together.

- Q: Tapered roller bearings 32010x, two matching, how to install?

- Bearing type: tapered roller bearingNew model: 32010XOld model: 2007110EInternal diameter (mm):50Outside diameter (mm):80Width (mm):19Tapered roller bearings are mainly used to support radial load and axial load, which should not be subjected to axial load alone.

- Q: The installation of tapered roller bearings

- 2, when installed, the direction of the roller tilt there is a regulation? Must be the same as the following picture?:You say that the direction of the tilt is actually the same direction of the bearings, the installation of the problem to different ah!

- Q: What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q: that is to say, the taper head is the face and the back is the back

- The installation of tapered roller bearings is not only to pay attention to the direction of installation, there are many other places to pay attention to, is a very professional technical activities

- Q: Tapered roller bearings, 70 in diameter, please tell me the model number

- What about outside diameter (D) and width (B)? You didn't say?.Following are all series of codes and sizes for tapered roller bearings (single column and double row). I hope they can help.Single row tapered roller bearings (taken from GB/T 297-1994)Bearing code |30000: 32914 X2Basic size /mm|d: 70Basic dimensions /mm| D: 100Basic size /mm|T: 20Basic size /mm|B: 19Basic size /mm|C: 16Installation size /mm|da (min):-Installation size /mm|db (max):-Installation dimension /mm| Da (min):-Installation size /mm|Da (max):-Installation size /mm|Db (min):-Installation size /mm|a1 (min): 4Installation size /mm|a2 (min): 6Installation size /mm|ra (max): 1Installation size /mm|rb (max): 1The other is /mm|a size: 19Other sizes /mm|r (min): 1Other sizes /mm|r1 (min): 1The calculated coefficient is |e: 0.33The calculated coefficient is |Y: 1.8The calculated coefficient is |Y0: 1Basic rated load /kN|Cr: 53.2Basic rated load /kN|C0r: 85.5The speed limit / (r/min) | fat: 3600The speed limit / (r/min) | oil: 4500The weight is /kg|W:-

Send your message to us

30230 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords