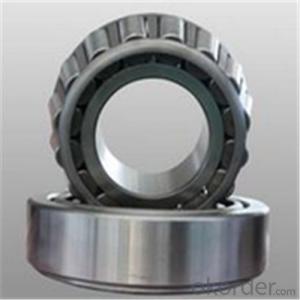

30226 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q: What are the conditions for the normal and reverse loading of tapered roller bearings?

- 2. anti loaded (outer ring width relative end) horns contact ball bearing or tapered roller bearing pressure center distance is greater than two at the midpoint of the bearing span, known as anti loading, obviously, axial thermal expansion will increase the axial clearance of bearing. In addition, the structure of reverse loading is more complicated, and it is inconvenient to assemble, disassemble and adjust.Stiffness analysis of positive and negative when the transmission parts of cantilever installation, shaft reverse mounting stiffness ratio of forward shafting high, this is because the distance from the center of pressure bearing with large, maximum bending moment of the bearing force, deformation and axial deformation and are less formal.

- Q: Is the tapered roller bearing so correct?

- For example, the middle roller you draw is cylindrical, and the roller of the tapered roller bearing is a frustum of a cone

- Q: How does the roller of tapered roller bearings fit in?

- Tapered roller bearings in the production of equipment, it is the first roller and cage assembly, and then into the inner ring, composed of components. Tapered roller bearings as long as the assembly, even if completed the inner ring, because the outer ring is only one ring.I don't know if you'll understand.

- Q: What items should be inspected for tapered bearings?

- 1, the tapered roller bearing without cracks, sharp edges, plants and rust; on the road has not agreed to the raceway of machining trace; super fine traces in the outer ring, the steel ball surface should be symmetrical task differences, not to have scratches, bumps;

- Q: Tapered roller bearing: Bearing expert why burned or locked

- Shaft tolerance is relatively small and fine head, the inner shell inside and nose has obvious signs of friction. If there are traces of friction on one side or on both sides of the inner shell, there is an abnormal contact with the inner shell of the bearing and the friction of the inner shell of the bearing.2, the inner shell shell burning marks are not serious, roller black even deformation, generally is the inner shell or casing tolerance, Ambassador bearing gap smaller, and even negative tolerance caused by burning. Or in the maintenance of the bearing selection is not correct, you can use large clearance bearings.3, the shell burned seriously, the inner shell, roller are no obvious changes, you can observe whether the shell has traces of friction. There are traces of friction on the outside, and it can be considered that the tolerance between the bearing shell and the shaft is insufficient, which results in abnormal friction caused by the slipping of the housing. If there are traces of friction on one side or on both sides of the shell, there is an abnormal contact between the component relative to the bearing housing and the bearing housing, and the heat generated by friction will be burned out.

- Q: Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.So, we use bearing technology or design personnel, only need to control your speed in the following catalog bearing manufacturers can.In addition, oil lubrication is better than grease lubrication at the same speed.

- Q: Tapered roller bearings. Are the rollers tapered?

- The cone can be seen as a right angled triangle revolving around a right angle, with a point at the top.

- Q: Online cylinder cones are GB/T4663, what do you mean?

- Which size do you want, eldest brother? How do I make so much?GB/T: recommended national standards; GB: mandatory national standards4663: taper roller national standard codeThere is a missing release year later!It should be: GB/T 4663-1994

- Q: Tapered roller bearing suffix code YA2 stands for what does that mean?

- SatisfyHappiness is merely material meet? Of course not, happiness is not simple and get food and drink happy nor personal desires superficial meet. Wealth has sometimes not happy, luxury, and happiness cannot lead a gay life equate. Therefore, the material does not meet the real happiness.It is the balance of happiness tends to meet the spirit of Confucius, "there are friends from afar" or "awfully";

- Q: Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- The utility model relates to a special measuring tool for the axial clearance of a tapered roller bearing, relating to a measuring tool used for measuring the gap between single row tapered roller bearings. Including about two relative PTFE gland set, the upper and lower ends of the gland in two PTFE is formed in the end of the notch, which formed a central notch, a notch in the center of the PTFE sleeve in the two or so is PTFE gland and PTFE sleeve are connected together by wing screw. The utility model has the advantages of greatly improving the measuring accuracy and accuracy, reducing the measuring error, and improving the maintenance efficiency and quality. It avoids the deviation in the maintenance process due to the different experience of the operator, and is simple and easy to operate.

Send your message to us

30226 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords