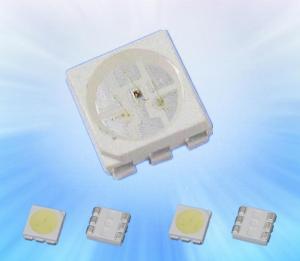

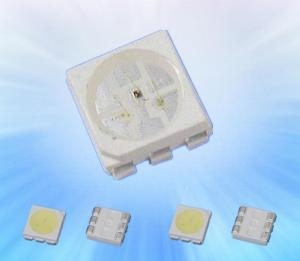

3014 SMD LED Component SMD Wholesale

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3014 SMD LED Component

1.VF:3.0-3.6V

2.Power:0.1W

3.Brightness:9-10lm/10-11lm

4.ISO9001 factory

3014 SMD LED Component

3014 SMD LED Component Features:

ABSOLUTE MAXIMUM RATING (Ta=25°C)

Item | Symbol | Value | Unit |

Peak Forward Current | IFp | 60 | mA |

Reverse Voltage | VR | 5.0 | V |

Continuous Forward Current | IF | 30 | mA |

Operating Temperature | Topr | -40 to 85 | °C |

Storage Temperature | Tstg | -40 to 100 | °C |

Lead Soldering Temperature | Tsol | 260°C For 3 Seconds | |

CHARACTERISTICS (Ta=25°C)

Parameter | Condition | Symbol | Min | Typ | Max | Units |

Power Dissipation | IF=30mA | Pd | - | 100 | - | mw |

Correlated Color Temperature | IF=20mA | CCT | 5000 | / | 8000 | K |

Forward Voltage | IF=20mA | VF | 2.8 | 3.2 | 3.8 | v |

Reverse Current | VR=5V | IR | / | / | 10 | μA |

Chromaticity Coordinates | IF=20mA | X | / | 0.31 | / | |

Y | / | 0.327 | / | |||

Luminous Flux | IF=20mA | φv | 5 | / | 9 | LM |

Luminous Flux | IF=30mA | φv | 7 | / | 13 | LM |

Color Rending Index | IF =20mA | CRI | / | 70 | / | Ra |

Full Viewing Angle | IF=20mA | 2θ1/2 | / | 120 | / | deg |

REMARK:1:1

Date | 2012-10-19 | Page | 1/1 | Model No. | SD3014WN | CHECKED |

|

REV No. |

A/0 |

Document No. |

1903014001 |

CUSTOMER |

|

APPROVED | Yucheng |

NOTE:

Testing tolerance: VF±0.1V, IV(Φv) ±10%, 2θ1/2±10% ,CCT(λD)±15%;

3014 SMD LED Component Application:

Indoor and outdoor lighting ,outdoor billboard, traffic lighting,car lighting ,LCD backlight portable and mobile lighting as flashlight , emergency lighting,and led dest lamp

- Q: What determines the brightness of the patch LED?

- Lamp brightness level itself, is also in the rated current situation, its brightness

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- (1): LED full color light emitting module display module is generally yellow green, pure green module price is more expensive; SMD full color LED display using pure green tube coreThe display module (2): LED full color pixel visual feeling is thick, low brightness, easy to have the mosaic phenomenon; patch LED full color consistent, high brightness;(3): maintenance module LED full color display is not easy to maintain, the whole module replacement cost is high; SMD full-color LED screen for easy maintenance, repair and replacement of single lamp;

- Q: What, in what way do I shunt the LED?

- LED lights are current driven, first of all, look at your LED's IF and VF values. How much power do you have?. Make sure the current is in line with the IF and the current limit can be achieved with resistors.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: Patch LED features

- The seismic resistance, high reliability, low operation cost system.It is easy to small, thin, lightweight, easy to shape without restrictions, made all kinds of application.

- Q: The quality of the LED patch module

- Quality of circuit board. In the same quality of LED, the quality of PCB will have an important impact on the life of LED. The circuit board is divided into aluminum plate, glass fiber board, semi glass fiber board and paperboard. The quality of aluminum is the best, the best cooling effect, but the cost is too high, the domestic manufacturers generally only in high-power LED products use, LED module manufacturers generally use cardboard, semi glass fiber and glass fiber board. Module, piranha, straw hat module monochrome is generally used in cardboard or semi glass, commonly used glass fiber or semi SMD glass fiber board. Colorful and full color module series generally at least half of glass fiber, so as to match.

- Q: Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q: How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- The welding speed and welding time because certainly give light foot heat, so the speed must be fast, tin wire and tip with better, while heating to tin iron head, avoid heating time is too long.

Send your message to us

3014 SMD LED Component SMD Wholesale

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 100000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords