300 Copper Continous Extrusion Machine with High Capactity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Extrusion Machine for all series

- The History of the copper extrusion machine

The Conform Extrusion/Copper Extrusion Machine is a newly-developed [Metal Plastic Processing Technology] .

- The Application of the copper extrusion machine

To produce:

l Copper bus bar from copper extrusion machine

l Copper flat wire from copper extrusion machine

l Copper round wire from copper extrusion machine

l Shaped copper material under approximate any size… …

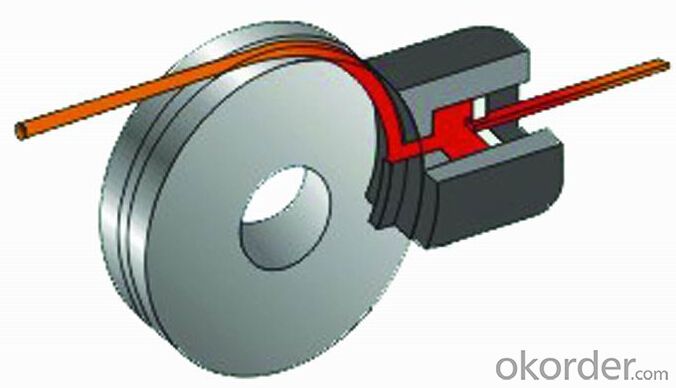

- The theory of the copper extrusion machine

Tooling and Steps of the conform theory:

[1] the continuously-rotating extrusion wheel,

[2] the frictional force between the wheel groove,

[3] continuous rod’s pulling,

[4] the plastic deformation happens inner the die chamber.

[5] And finally the output is extruded out.

For continuous cladding process, two aluminum feed-stocks are employed, and the chamber is fitted on the upper position of the extrusion wheel. The core wire or steel wire is fed in the tangential direction, and the aluminum feed-stocks are formed into the aluminum pipe through the chamber, then the aluminum pipe wraps around the core wire to be formed into the cladding or sheathing product.

The revolving extrusion wheel is driven by a motor, and it guides the feedstock to enter the wheel groove. The feedstock is dragged into the chamber by the friction between the wheel groove and feedstock. The friction generates high temperature and heavy pressure, under the high temperate and pressure, the metal is formed into the pipe or profile through a die.

Advantages of copper extrusion machine

1. Lower energy consumption

2. Better microstructure

The continuous extrusion method use oxygen free copper rod and has natural closed space during extruding and can easily produce oxygen free copper bar. It is impossible for the traditional process.

3. Higher material using ratio

The excess stock of traditional extrusion process and waste heads after drawing process cause low utilization ratio of material

4. Lower labor and processing cost

The traditional process needs more manpower and great worker's labor intensity,

Tech. parameters of production line | ||||

Type | SNLD350 | SNLD400 | SNLD500 | |

Nominal Diam. of extrusion wheel (mm) | 350 | 400 | 500 | |

Material type (Up-ward oxygen free copper rod) | Pure copper /brass copper | Pure copper /brass copper | Pure copper /brass copper | |

Max. product width (mm) | 80 | 170 | 240 | |

Max. sectional area (mm²) | 600 | 2000 | 3800 | |

Production capacity (kg/h) | 860 | 1300 | 2000 | |

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed.

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine ideal

- Q: What raw material does the extruder use?

- The utility model has the function that the plastic melt from the extruder barrel is well distributed in the die runner so as to be extruded and formed from the die at a uniform speed. The forming action of an extrusion die is in the process of complete extrusion (see plastics processing). A plastic extruder consists of an extrusion system, a drive system and a heating and cooling system. The classification system of extrusion system includes 1. extrusion screw, barrel, hopper, head, and mould, plastic extrusion system by plasticizing evenly into the melt, the establishment of Liu Hesheng basic information name in this process and Liu Hesheng taught: - professional engineering

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc. 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- It depends on experience, and the lines made by squeezing it are solid. When you make the line, you can see the expansion and skewness of the material!

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

Send your message to us

300 Copper Continous Extrusion Machine with High Capactity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches