3 Plastic Pipe Fittings PPR All Plastic Fittings Pipe Plastic Material Long Plug 1/2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

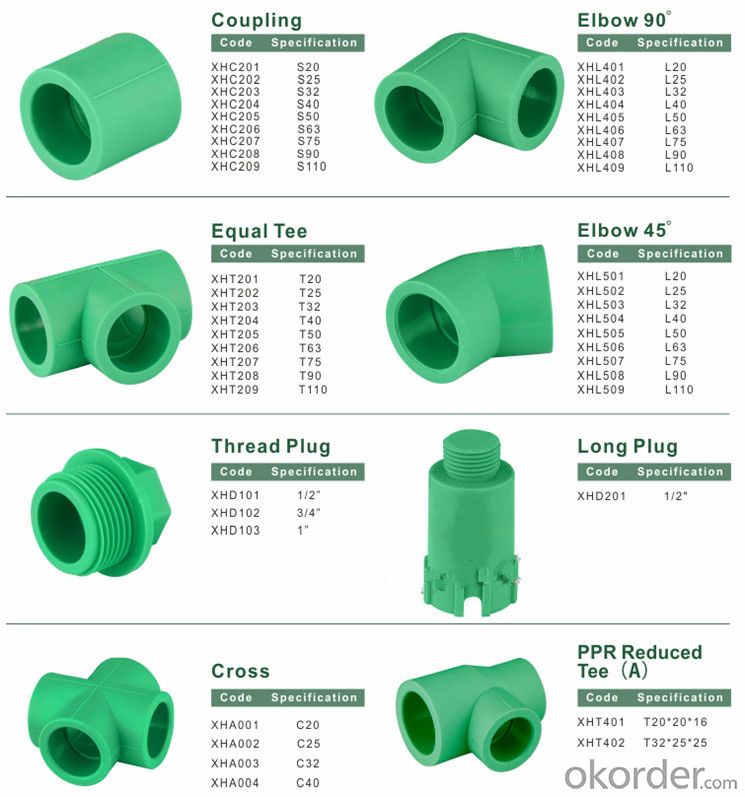

Specifications of PPR fittings pipe plastic material

1. size: 40-110mm

2. universal or OEM ODM

3.No heavy metal additives

China polypropylene fittings pipe plastic material of PPR fittings pipe plastic material

Recycled and Environmental friendly.

Applications of PPR fittings pipe plastic material:

1) Water supply systems: civil and industrial constructions, in residential buildings, hospitals,hotels,

school and office buildings, ship, building

2) Drinking water systems & food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities: swimming pools & stadiums

6) Rainwater utilization systems

Features & Advantages of PPR fittings pipe plastic material:

1.Sanitization & Non-poison: It is green building material without heavy metal additives,able to be used for pure clean drinking water pipe system.

2.High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

3.Corrosion-proof & Non-fouling: Resist chemical matters & electron chemical corrosion, avoiding fouling,blocking, blemish, rust on basin and bath.

4.Beautiful Appearance & Higher Flow Capacity: Smooth inner and outer surfaces, les flowing resistance,

soft color and beautiful figure.

5.Easy and Reliable Installation: Using heat melting joint without sleeve wire, and taking few seconds for connecting and adopting good quality copper inserts to connect the metal pipe and basin.

6.Long Using Life: able to be used for over 50 years under normal condition.

Sizes of PPR fittings pipe plastic material:

Pictures of PPR pipes and fittings

Packing of PPR pipes and fittings:

FAQ:

1. why choose our factory ?

we are the professional ppr maufacuter the products series is very completely .

we have the professnial exported team more exprience ,reasonable price and best sales service . we have office

all overthe world .the customer is spread over the world .the exported market is the southeast ,asica,the

north and south america ,the european and middle east place so on !

2.How to order?

do not hesitate to contact by online or Email as soon as possible once you are interested in our products. The specific quotation will be offered basing the request dimension and quantity.x

3. Can you offer sample pipes and visit my factory?

Yes, we can. But as usual, the buyer have to pay the shipment fee for the sample.

4. What about the quality?

all products according to ISO and National highest standard, also we can offer CE, ASTM certificate if necessary. The guarantee and insurance is 50 years upon rational usage.

5. What payment is available?

Most payment method is available such as L/C, T/T and so on. At usual, 30% t/t deposited before producing and 70% C/L upon B/L for huge purchase.

6.the advantage for us ?

You may be looking for good plastic supplier hard, and you may waste of much time to find similar products at simiar price, and maybe some trading company is wasting your time to chose by higher price .P send your purchase list and you will see how professional we are.

7.Guaranteed:

If products’ quality don’t accord to discription as we give or the promise before you place order,

we promise 100% refund.Our service formula: best quality+best price+best service=customer’s trust

- Q: Can plastic pipe fittings be used for HVAC systems?

- Yes, plastic pipe fittings can be used for HVAC systems. Plastic fittings, such as PVC or CPVC, are often used in HVAC applications due to their corrosion resistance, durability, and ease of installation. However, it is important to ensure that the plastic materials and fittings used are compatible with the specific HVAC system and meet the necessary codes and standards.

- Q: Are plastic pipe fittings compatible with compression couplings?

- Yes, plastic pipe fittings are compatible with compression couplings.

- Q: Spiral drain pipe fittings are not special pipe fittings

- NoThe drainage tube is made of high density polyethylene (HDPE) and other additives the exterior is a new drainage plastic pipe corrugated, corrugated pipe is through holes in the permeable groove tube around the outside of the outsourcing geotextile acupuncture and processing. According to the types of bellows, they can be divided into single wall permeable bellows and double wall permeable bellows.

- Q: What is the maximum temperature that plastic pipe fittings can handle?

- The maximum temperature that plastic pipe fittings can handle depends on the specific type of plastic used. However, most plastic pipe fittings can typically handle temperatures up to around 140°F (60°C) before they start to degrade or deform. It is important to consult the manufacturer's guidelines or specifications for the specific type of plastic pipe fittings being used to ensure safe and proper usage.

- Q: Are plastic pipe fittings more cost-effective than metal fittings?

- Plastic pipe fittings are generally considered to be more cost-effective than metal fittings. They are typically cheaper to manufacture, purchase, and install due to their lower production costs and lightweight nature. Additionally, plastic fittings do not require additional coatings or treatments for rust protection, which further reduces their overall cost. However, it is important to consider the specific application and requirements before deciding as certain scenarios may benefit from the durability and longevity of metal fittings despite their higher initial cost.

- Q: Are plastic pipe fittings resistant to oil and grease?

- Yes, plastic pipe fittings are generally resistant to oil and grease.

- Q: Are plastic pipe fittings suitable for wastewater treatment plants?

- Yes, plastic pipe fittings are suitable for wastewater treatment plants. They are commonly used due to their resistance to chemical corrosion, durability, and cost-effectiveness. Plastic fittings also offer ease of installation and maintenance, making them a popular choice in wastewater treatment facilities.

- Q: Do plastic pipe fittings require any special tools for removal?

- Yes, plastic pipe fittings often require special tools for removal. These tools may include pipe wrenches, pliers, or specialized fittings removal tools, depending on the type of fitting being used.

- Q: Are plastic pipe fittings resistant to pressure surges?

- Yes, plastic pipe fittings are generally resistant to pressure surges. Plastic materials such as PVC and CPVC are designed to withstand sudden increases in pressure without deformation or failure, making them suitable for handling pressure surges in plumbing and industrial applications. However, it is important to ensure that the fittings are properly installed and meet the required standards to ensure their maximum resistance to pressure surges.

- Q: Can plastic pipe fittings be used for pharmaceutical manufacturing?

- No, plastic pipe fittings are typically not used for pharmaceutical manufacturing as they may not meet the strict quality and safety standards required in the industry. Stainless steel or other specialized materials are commonly used in pharmaceutical manufacturing to ensure product integrity and prevent contamination.

Send your message to us

3 Plastic Pipe Fittings PPR All Plastic Fittings Pipe Plastic Material Long Plug 1/2

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords