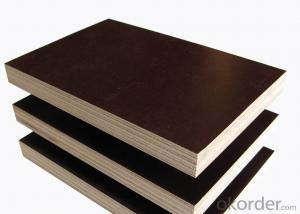

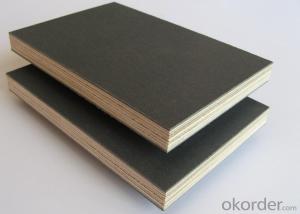

3/4 in Plywood Actual Thickness Black and Brown Film Faced Pywood 18x1250x2500mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

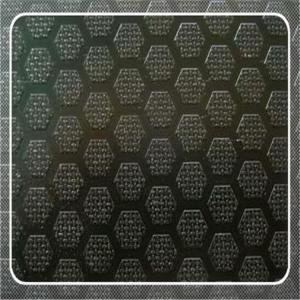

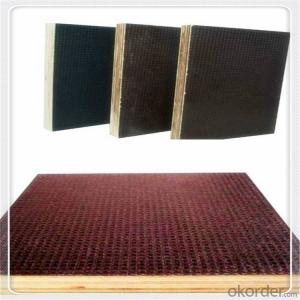

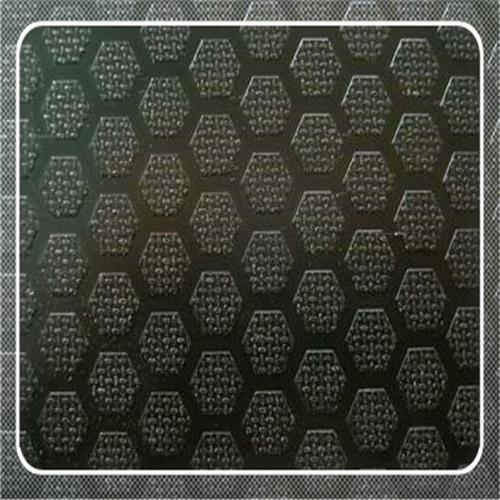

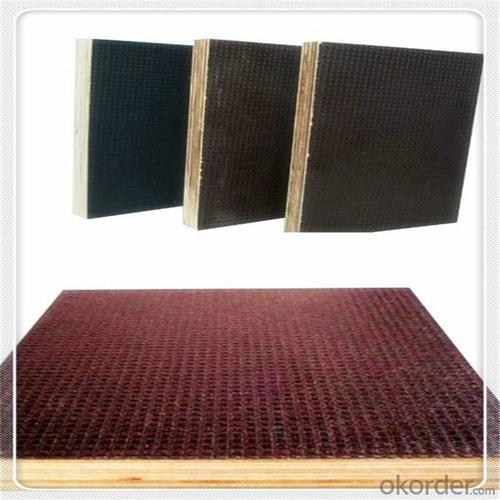

FILM FACED PLYWOO | |

Face and back | brwon/black/red film face. |

Core | poplar/Birch/hardwood/combi |

glue | wbp:dynea phenolic/melamine |

Size | 1220*2440mm, 1250*2500mm,or small sizes as your request. |

Thickness | 9/12/15/18/21mm |

Density | 520-700KG/M3 |

Tolerance of thickness | +/-0.5mm or as your request |

Moisture | 8%--15% |

Face and back weight | 80/120/240g/m2 |

Usage | construction, can be used for more than 10 times |

Certificate | |

Packaging & Shipping

Standard export packing with pallets. one is with carton board four sides, the top and bottom is with plywood packing.

the other is with 3mm plywod packing on four sides. the top and bottom is with thick plywood. Inner is with plastic film

FCL Loading with 18pallets/container,8 pallets/20GP.

Delievery Time: within 15 days after deposit/lc at sight.

Our Services

Supply film faced plywood,furniture plywood and flooring basic plywood with top quality.

Supply FSC/CE/ISO9001 Certificates

Supply best after-sales service.

Capacity:6000M3/month

Payment term:TT and LC

Contact:david zhao

Skype:davidz19627

mobile/whatsapp:00861346813389

Email:tomszhao@163.com

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Hard fiber board is also a density board, but its density is above 0.80g / cm3. Divided into one side of the light, the other side of the textured side of the hard fiber board and two-sided hard fiber board two.

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: How do I determine if plywood contains formaldehyde?

- The plywood itself is easy to identify because each side can see the shavings that are pressed together, but it becomes hard to find it after making furniture

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: The Preparation of plywood ingredients

- core core core sandwich panel or composite plywood center layer. Usually its thickness is greater than the other layers.

- Q: What is the difference between plywood glue E0E1?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What are the defects of the plywood?

- The intergrown knots are formed by the tree's live technique. Knots and the surrounding wood close together or with the surrounding wood part of the length of its cross-section than the length of 3/4, hard texture, normal structure

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Appearance level, size, physical and mechanical properties of the three tests are qualified to determine the product is a qualified product, or judged to be unqualified. P

Send your message to us

3/4 in Plywood Actual Thickness Black and Brown Film Faced Pywood 18x1250x2500mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords