3.2m Fiberglass FRP gel coat flat panel special for truck body making machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

This production line can produce lighting sheet, color sheet, common flat sheet, gel coat sheet.

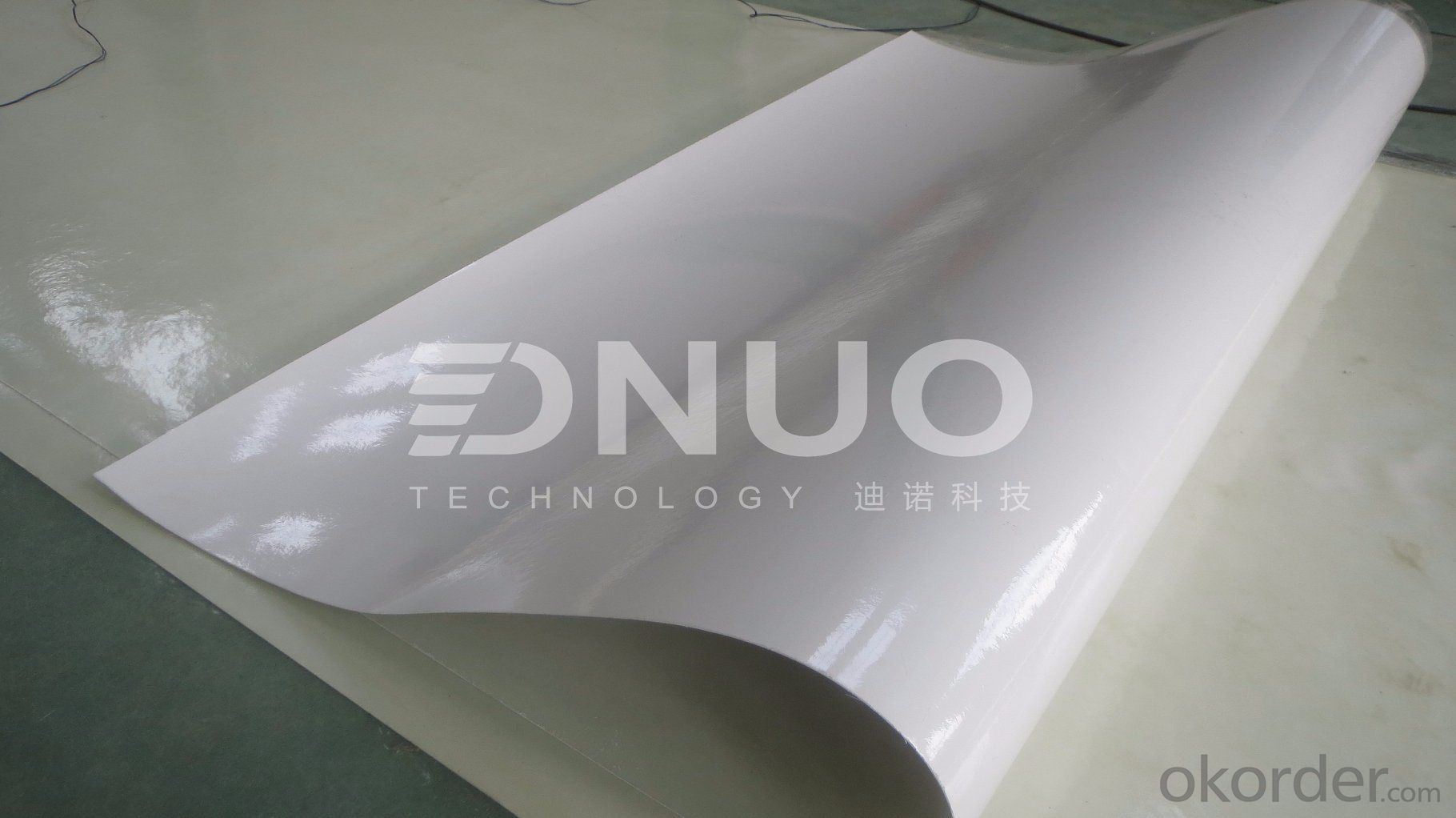

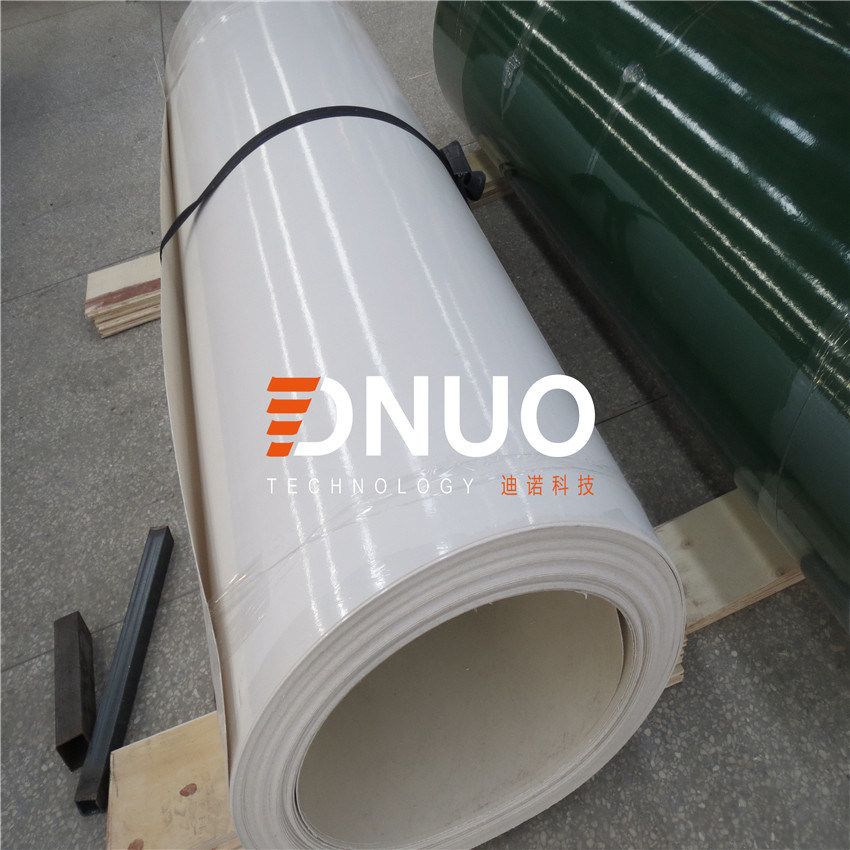

Products Show

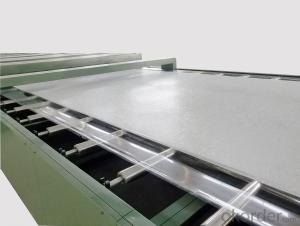

Process production

Machine character

1、 Apply high precision import forging doctor blade, smaller error, Thin & even gel coat coating.

2、 Gel coat curing area apply clip flatten roller designed by Dnuo technology company, easy operation & good tensioning effect.

3、 The impregnation table can control temperature independently & accurately. It can adapt to the outside temperature fast, impregnation fast and improve the production speed effectively.

4、 Pulse free metering system, accurate metering, and wide flow rate adjustment range. It can add powder filler.

5、 Easy operation based on PLC intellectual control system. Operate by two computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

6、 Three separate ovens for temperature control, Unique temperature control arithmetic makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively. This way makes sheets curing better.

7、 Metering control system and Roving chopper speed can be synchronous with the production line.

8、 Special cross cutting machine and good synchronization performance make cutting accurately..

9、 All the machine parts adopt international standard steel make machine with high stability.

10、System failure can be automatically alarmed and show fault point. Make maintenance easily.

11、Particular parts adopt special purpose wire, durable in use.

12、Size and layout of machine can be made according to customer requirements

13、Electric system adopt siemens brand.

Our Factory

We are professional manufacturer of FRP sheet production line. We are the first domestic production of FRP sheet making machine and biggest-selling company. We can provide many types of FRP sheet forming production lines, like FRP lighting sheet production line, FRP gel coat sheet production line, FRP embossed sheet production line and FRP decorative sheet production line etc. Dnuo has occupied more than 60%-70% domestic market with obvious advantage. The product has been exported to the USA, Saudi Arabia, Jordan, India, Indonesia, Malaysia, Vietnam and Azerbaijan etc.

Over the years we have been focusing on the FRP sheet continuous forming techniques. We have successfully provided the professional FRP sheet continuous shape forming equipment to several well-known enterprises domestic and abroad. We provide a perfect solution to enterprises who aim at high efficiency production of high quality FRP sheet.

Exhibition

After sale service

Package

For the large-sized parts, we take some measures to fix them.

For the other parts,we pack them with polywood.

we declare that we will try our best to pack

our goods well make them arrive in destination safely.

Guarantee and After-sale Service

1. Guarantee for 1 year excluding wear and electrical parts. Extra fee is paid if out of date. Any damage to the machine caused by improper use will be charged.

2. The equipment is fully test before delivery

3. Free installation, training and commissioning on site to help the operators operate as soon as possible

4. We will provide wear and electrical parts at an agency price when you need replacement.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory. Certainly if you need other special product, we will do our bestto help you, so we can build a long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

Q: Why we are your best choice?

A: We have direct factory and many years of export experience, and offer the best price withhigh quality product, timely delivery, also have good after-sales service, therefore with goodreputation on boards and with many clients have good long-term business relationship.

Q: How many years experience do you have in this industry ?

A: Our factory was established in 1999, thanks for 17 years old development, our design and production team became stronger and stronger.By now we have became the fist large scale enterprise on this field.

- Q: What are the methods of forming plastic products introduced in this course?

- 6 、 heating moldingHeat - forming thermoplastics are used to heat the plastic sheet into an elastic state and then press it to form a mold attached to the mold. Production of dishware, disc type products.7, foaming moldingThe foaming molding adds the foaming agent to the foam, then the foam is injected into the mold and is solidified into a product. The utility model is used for making cushioning packages for precise instruments and meters.8, moldingMolding for thermosetting plastics. This is a powder, flake or granular thermosetting resins and additives, directly close mold in mold, heating, pressurizing, plastic and liquefaction, chemical reaction and curing, cooling after the products. Producing plates and electrical appliances, machinery parts,9, casting jade moldingCast molding for thermosetting plastics. The molding powder into the barrel heating to heat plasticizing, pressed into the mold, and the product complete solidification under pressure. Complex products production needs to block metal objects.10, casting moldingCast molding is used to heat resistant plastics. It is a thermosetting plastic that is plasticized and injected into the mold. It is cured at atmospheric pressure, cooled and released

- Q: How much is the general control of plastic products profit? Thank you

- 20%, the profit specification. Our plastic material only 20% gross profit, the finished product should be more than 20%.

- Q: Which plastic is suitable for processing 3mm threaded holes and is best resistant to corrosion?

- Nylon plastic is suitable for processing 3mm thread hole, nylon is widely used in chemical machinery, corrosion protection equipment, gear and parts, broken material.

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Moreover, the after-sale service of the manufacturer is very good. So it works very well. I recommend you to Shandong Qufu (Confucius's hometown) to look at the side of field visit, actually there's a purchase as clear as noonday, Shengxin machinery Bao Aiqing is the manager of a professional, give you a ball 897026688 and ask what questions or ask professional better.

- Q: What method or machine do you want to throw bright?

- Some plastic products come out very smooth, not in plastic polishing, polishing on the mold

- Q: What kind of machinery does a plastic product factory need?

- See what you want to produce, pipe, pipe machine, what do you need to do? I can help you with it. The price should be cheaper than that of the whole set. The quality is the same as the quality of the whole set of equipment!

- Q: I would like to ask you how to produce plastic products, the need for mold, but also the need for large machinery, thank you all

- Depending on what you do, different products have different requirements. Plastic products are injection molding, extrusion, injection blowing, extrusion and blowing equipment.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- How big is the product? How big is the injection machine? The machine has been bought. Waste of electricity and high price; the product made by buying small is not good. The injection machine 100 grams may in 6 to 8, in case Taiwan, {brand is not the same, the price difference is very big. } to do PA, if it is enhanced, it is necessary to do special screw and barrel, wear-resistant.

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

3.2m Fiberglass FRP gel coat flat panel special for truck body making machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches