2024 New Plastic Tubes PPR Pipe Fitting for Hot or Cold Water Expansion Valve High Class Quality Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

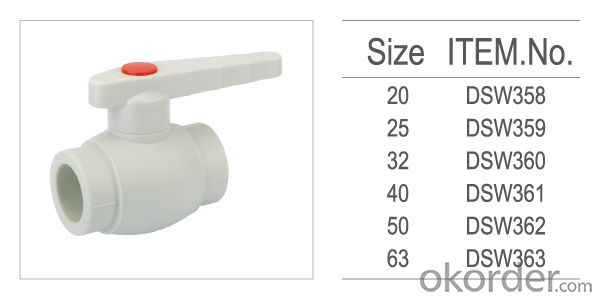

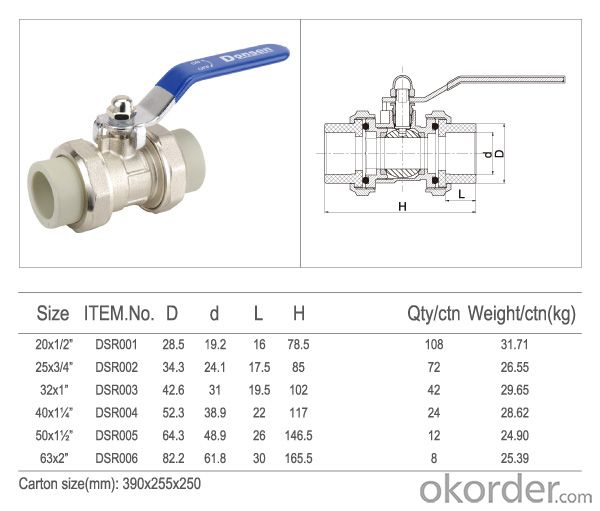

Specification

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Advantanges

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Can plastic tubes be used for chemical dispensing?

- Yes, plastic tubes can be used for chemical dispensing as long as the plastic material is compatible with the specific chemicals being dispensed to avoid any reactions or contamination.

- Q: How do plastic tubes compare to ABS tubes in terms of impact resistance?

- In terms of impact resistance, plastic tubes generally offer lower resistance compared to ABS tubes. ABS (Acrylonitrile Butadiene Styrene) tubes are known for their superior impact resistance, making them more resilient to accidental drops or heavy impacts. Plastic tubes, on the other hand, may be more susceptible to cracking or breaking when subjected to the same level of force.

- Q: Are plastic tubes resistant to UV discoloration?

- Yes, plastic tubes are generally resistant to UV discoloration. They are designed to withstand exposure to sunlight and other environmental factors without fading or discoloring.

- Q: Can you smoke hookah with just a plastic tube?

- no, you need something to put the hookah in, and you need something to light it. And you don't want to burn the plastic and breathe the fumes!

- Q: If a kid has to be intubated due to a respiratory infection, what do they do? Do they keep you asleep until you can breathe on your own while you're intubated or can you be awake while the tube is in? How long do they usually leave it in? How do they put it in if you're in respiratory distress?

- When someone needs to be intubated, they place narrow plastic tube down into their throat, just above the patients lungs. This can be done in respiratory distress. How long the tube stays in place all depends on how sick the patient is. That can be days to weeks. The patient is usually sleeping to help them breath more easily with the ventilator, but if someone is able to remain comftorble, they may allow them to be more awake.

- Q: What are the plastic pipes that can be welded?

- General PP, PE pipe can be used hot melt welding, using PVC glue adhesive.

- Q: I pick up trash off the road today, it was like plastic tube and kinda like a cement thing, a lil farther down I saw a dead raccoon, when I got home I ate but forgot to wash my hands does this means I have rabies?I went over the raccon with my bike also and I kinda leaned on the tire after I ran it overIs there any chance tha I have rabies?

- Did you film it? This is Home All Categories Computers Internet Internet YouTube .

- Q: How do plastic tubes perform in high-altitude environments?

- Plastic tubes generally perform well in high-altitude environments due to their lightweight and durable nature. However, their performance can vary depending on factors such as temperature fluctuations, pressure changes, and exposure to UV radiation. It is important to choose appropriate materials and designs that can withstand these conditions and prevent any potential degradation or failure.

- Q: What are the advantages of using plastic tubes in the medical industry?

- There are several advantages of using plastic tubes in the medical industry. Firstly, plastic tubes are lightweight and flexible, allowing for ease of use and manipulation during medical procedures. They are also transparent, enabling healthcare professionals to easily monitor the flow and contents of fluids. Additionally, plastic tubes are highly durable and resistant to breakage, reducing the risk of contamination and ensuring patient safety. Moreover, plastic tubes can be manufactured in various sizes and shapes to accommodate different medical applications, making them versatile and adaptable. Lastly, plastic tubes are cost-effective compared to other materials, making them a practical choice for healthcare facilities.

- Q: How do plastic tubes compare to polycarbonate tubes in terms of impact resistance?

- Polycarbonate tubes generally have higher impact resistance compared to plastic tubes.

Send your message to us

2024 New Plastic Tubes PPR Pipe Fitting for Hot or Cold Water Expansion Valve High Class Quality Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords