2024 New Half Inch Plastic Pipe Fittings PPR Micro Solenoid Valve for Hot or Cold Water from China Professional

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Advantages

1.We named this kind of fittings as PPR reducing sleeve. ppr reducing coupling

2.A whole part of this PPR reducing sleeve is made of polypropylene.

3.As you know, all the fitting designed for connecting the pipe or change the piping path. This PPR reducing sleeve is able to connect the different diameter pipeline together. I believe you know how to use it.

4.All of these PPR pipe fitting come in 3 different colors: white, gray, green.

5.Our PPR pipe fitting had been pasted the ISO9001 authentication. And had been got the CE certification.

6.These PPR reducing sleeve makes use of completely 100% new PPR material import from Korea. To be ensured that it is much healthier than the pipe make use of the reclaim plastic.

7.We adopt the newest technology in the piping produce industry.

8.We had been piping manufacturer for over 10 years. And we are good at this.

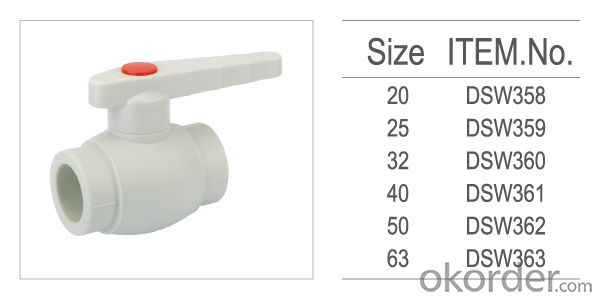

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

Product Show

Main Product Features:

1. Large drum hub to maximize cable life

2. Self-activating automatic brake hold the load securely when crank handle is released

3. With cable or strap

4. Safety guard cover available

5. Top quality with competitive price

6. Widely used in the double beam bridge crane and gantry crane

7. Easy to install and high quality

8. Compact structure and reasonable design

9. Could be mounted on t he ground or wall!

10. Double drum!!

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Can plastic pipe fittings be used for food processing systems?

- No, plastic pipe fittings are not suitable for food processing systems as they can potentially leach harmful chemicals into the food, compromising its safety and quality. Stainless steel or food-grade materials are recommended for such applications.

- Q: What are the characteristics, properties and uses of PVC plastics?

- PVC can be divided into soft PVC and hard PVC. Among them, hard PVC accounted for about 2/3 of the market, soft PVC accounted for 1/3. Soft PVC is generally used for flooring, ceiling and leather surface, but because the soft PVC contains softening agent (this is the difference between soft and hard PVC PVC), crisp, not easy to save, so the range of use is limited. The hard PVC does not contain softener, therefore, the utility model has the advantages of good flexibility, easy molding, uneasy brittleness, no poison, no pollution and long storage time, so the utility model has great development and application value. The essence of PVC is a kind of vacuum blister film. It is used in the surface packing of various panels, so it is also called decorative film and adhesive film. It is applied to many fields such as building materials, packaging, medicine and so on. Among them, the building materials industry accounted for the largest proportion, 60%, followed by the packaging industry, as well as other small range of applications.

- Q: Are plastic pipe fittings resistant to ground settlement?

- Plastic pipe fittings can vary in their resistance to ground settlement depending on the specific material and design. However, generally speaking, plastic pipe fittings are less rigid compared to metal fittings, which can make them more prone to movement and displacement in the event of ground settlement. It is important to consider factors such as the type of plastic used, the depth of the pipe installation, and the soil conditions when determining the overall resistance to ground settlement.

- Q: Are plastic pipe fittings resistant to high-temperature chemicals?

- Yes, plastic pipe fittings are generally resistant to high-temperature chemicals.

- Q: Do plastic pipe fittings require any special grounding or bonding?

- No, plastic pipe fittings do not require any special grounding or bonding as they are non-conductive and do not carry electrical currents.

- Q: What is the PVC pipe fitting?

- PVC pipe (PVC-U pipe) rigid PVC pipe is made of PVC resin and stabilizer, lubricant and so on. It is extruded and formed by hot pressing method. It is the earliest plastic pipe to be developed and applied. PVC-U pipes are corrosion resistant, easy to adhere, low in price and hard in texture, but because of the exudation of PVC-U monomers and additives, they are only suitable for the feed water system with a temperature of not more than 45 DEG C. Plastic pipes are used to transport potable water, waste water, chemicals, heating and cooling fluids, foodstuffs, ultrapure liquids, slurries, gases, compressed air, and vacuum systems.

- Q: Are plastic pipe fittings resistant to extreme temperatures?

- Yes, plastic pipe fittings are generally resistant to extreme temperatures. However, the specific type of plastic used in the fittings can determine the extent of their temperature resistance. Some plastic materials are designed to withstand high temperatures, while others may have limitations. It is advisable to consult the manufacturer's specifications or guidelines for the specific plastic pipe fittings in question to determine their temperature resistance capabilities.

- Q: What is the maximum temperature that plastic pipe fittings can withstand?

- The maximum temperature that plastic pipe fittings can withstand varies depending on the type of plastic used. Generally, most plastic fittings can withstand temperatures ranging from 140 to 180 degrees Fahrenheit (60 to 82 degrees Celsius). However, it is important to consult the manufacturer's specifications for the specific type of plastic fitting to ensure it can handle the desired temperature.

- Q: Do plastic pipe fittings have a maximum operating flow rate?

- Yes, plastic pipe fittings typically have a maximum operating flow rate. This rate is determined by the design and material of the fitting, as well as the pressure and temperature conditions it will be subjected to. It is important to consult the manufacturer's specifications and guidelines to ensure that the flow rate does not exceed the recommended limits for the specific fitting being used.

- Q: Can plastic pipe fittings be used for rainwater harvesting systems?

- Yes, plastic pipe fittings can be used for rainwater harvesting systems. Plastic fittings are commonly used in rainwater harvesting systems due to their durability, affordability, and resistance to corrosion. They provide a reliable and efficient way to connect and distribute water from gutters and downspouts to storage tanks or other collection points. Additionally, plastic fittings are lightweight and easy to install, making them a popular choice for DIY rainwater harvesting projects.

Send your message to us

2024 New Half Inch Plastic Pipe Fittings PPR Micro Solenoid Valve for Hot or Cold Water from China Professional

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords