1/2 Plastic Pipe Fittings - 2024 New PPR Pipe Fitting for Hot or Cold Water Orbital Ball Valve Made in China Professional

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: Zhejiang, China (Mainland)

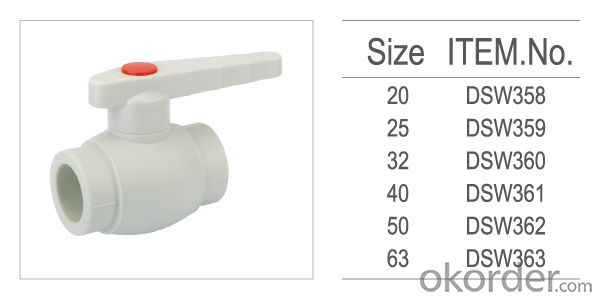

Model Number: DSW358-363

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Excellent heat-insulation property from minimum thermal conductivity

4) Lightweight, convenient to transport and handle, good for labor-saving

5) Smooth inner walls reduce pressure loss and increase flow speed

6) Sound insulation (reduced by 40% compared to galvanized steel pipes

7) Light colors and excellent design ensure suitability for both exposed and hidden installation

8) Recyclable, environment-friendly, accords with GBM standards

Applications

1. Distribution for cool and hot water;

2. Duct for drinkable water system;

3. Pipes for kinds of high-temperature and low-temperature heating system;

4. Pipes for heating and coolling settings in solar energy system;

5. Connecting pipe for air conditioners.

FAQ

Q1:How can i get a sample?

A1: You can get samples by communicate with our export sales.

Q2:How long is delivery?

A2:Delivery time will be 30-45 days according to order quantity.

- Q: Are plastic pipe fittings resistant to wear and tear?

- Yes, plastic pipe fittings are generally resistant to wear and tear. They are designed to withstand regular use and exposure to various elements without deteriorating or becoming damaged easily. However, the level of resistance may vary depending on the specific type and quality of the plastic used in the fittings.

- Q: What is the lifespan of plastic pipe fittings?

- The lifespan of plastic pipe fittings can vary depending on various factors such as the type of plastic used, the quality of the fittings, and the conditions they are exposed to. However, on average, plastic pipe fittings are known to have a lifespan of around 50-100 years.

- Q: Can the PPR pipe be injected with the same pipe as the PVC pipe?

- Used machines look at machine precision. The main view is whether the template is even, and whether the track is worn badly. Second, look at the circuit is chaotic, chaotic, indicating that many times the maintenance, the oil circuit is leaking, leakage, that is already very old.

- Q: Can plastic pipe fittings be used in fireproof systems?

- No, plastic pipe fittings cannot be used in fireproof systems. Fireproof systems require materials that can withstand and resist high temperatures, such as metal fittings.

- Q: Are plastic pipe fittings suitable for laboratory installations?

- Yes, plastic pipe fittings can be suitable for laboratory installations. They are commonly used in laboratories due to their corrosion resistance, durability, and affordability. Additionally, plastic pipe fittings are easy to install and maintain, making them a popular choice in laboratory settings.

- Q: Natural gas aluminum pipe, what fittings are best used?

- Aluminum plastic pipe in the installation and use, should try to avoid small radius bending, in order to prevent the aluminum tube part of the rupture; at the same time avoid connecting pipe buried in the wall, underground, in order to facilitate inspection and maintenance.

- Q: PSP plastic steel composite pressure pipe has several ways of connecting

- (3) it can be installed without any anti-corrosion treatment, thus saving the project cost.(4) the complete steel pipe layer is the main pressure bearing layer of the pipe body, so the bearing capacity of the pipe is not affected by the change of the plastic layer.(5) it has excellent sealing performance, anti stripping, easy to install, and also has the adaptive ability of various deformation of pipes and pipelines.

- Q: What are the machines for making plastic plugs?

- Plastic plug production machine: material drawing machine, cold heading machine, injection molding machine, wire rolling machine, CNC lathe, etc..

- Q: Are plastic pipe fittings resistant to sunlight exposure?

- Yes, plastic pipe fittings are generally resistant to sunlight exposure.

- Q: How do plastic pipe fittings compare to metal fittings?

- Plastic pipe fittings are generally less expensive, more lightweight, and easier to install compared to metal fittings. However, metal fittings are typically more durable, have higher heat resistance, and offer better pressure handling capabilities. The choice between plastic and metal fittings depends on the specific application, budget, and desired performance.

Send your message to us

1/2 Plastic Pipe Fittings - 2024 New PPR Pipe Fitting for Hot or Cold Water Orbital Ball Valve Made in China Professional

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords