2016 widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

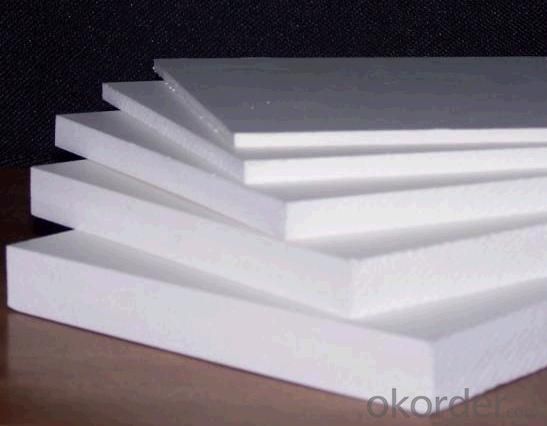

3. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

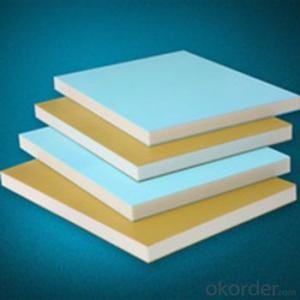

4. Pictures

- Q: Pollution in the production of plastic raw materials from petroleum production

- Petroleum - intermediate - polymerization monomer - resin - plastic particles - plastic products, the process of the above, each will have pollutants!

- Q: What material is best for plastic gears?

- The most commonly used is the POM. It can be made of carbon fiber reinforced, more stable size, of course, can also use high-end engineering plastics, such as: PEEK, SP-1, Teflon, LR, and so on. For different occasions, different characteristics of the use of choice

- Q: How many kinds of plastic do you have?

- General plasticsThere are five kinds of general plastics, namely polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and acrylonitrile butadiene styrene copolymer (ABS)

- Q: What are the POE plastic raw materials?

- Poe plastic raw materials are polymers of ethylene and butene, polymers of ethylene and isobutene.

- Q: Dissolve in 0.3 of the LDPE plastic raw materials what?

- The molecular structure of the conventional LLDPE is characterized by its linear backbone, with only a few or no long branched chains, but contains some short branched chains. Without long branched chains, the crystallinity of polymers is higher.In general, LLDPE resins are characterized by density and melt index. The density is determined by the concentration of comonomer in the polymer chain. The comonomer concentration determines the short branch chain in the polymer. The length of the short branched chain depends on the type of comonomer. The higher the concentration of comonomer, the lower the density of the resin. In addition, the melt index is a reflection of the average molecular weight of the resin, mainly determined by the reaction temperature (solution method) and the addition of chain transfer agents (gas phase method). The average molecular weight is independent of the molecular weight distribution, and the latter is mainly influenced by the type of catalyst.

- Q: What raw material (HDPE) made of plastic bags, high transparency, good sense of light master?

- Fillers, also called fillers, can improve the strength and heat resistance of plastics and reduce costs. For example, adding wood powder to phenolic resin can greatly reduce the cost, and make phenolic plastic one of the cheapest plastics, and can also significantly improve the mechanical strength. Packing can be divided into two kinds of organic fillers and inorganic filler, the former such as wood powder, rags, paper and all kinds of fabric, the latter such as glass fiber, diatomite, asbestos, carbon black.

- Q: ABS plastic storage conditions

- If it is ABS raw materials, storage: rainproof, moisture-proof, anti lightPacking is best provided with a PE inner bag for moisture proofThere is no place to pay more attention.

- Q: PVC what is the difference between raw and recycled raw materials?

- Products using recycled materials are brittle, easy to break or burst, very durable.

- Q: PP plastic stool surface with those raw materials, what is the ratio?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water).

- Q: I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- PC lenses also have an important feature, that is, PC lenses have the effect of isolating harmful ultraviolet rays, but their disadvantages also include surface scratching easily.

Send your message to us

2016 widely perfect high quality PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches