18KG/M Stainless steel billet for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 18KG/M Stainless steel billet for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

18KG/M Stainless steel billet for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's 18KG/M Stainless steel billet for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

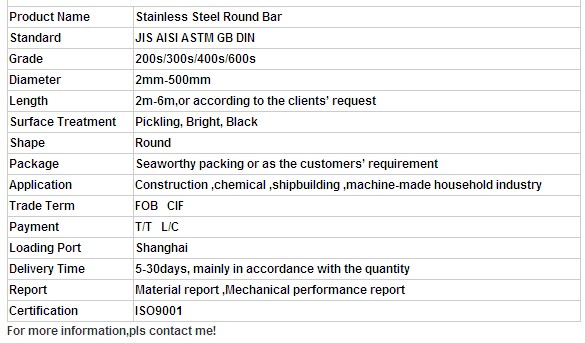

Product Specifications:

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: On the market, 8mm Round Bar is not 9 meters a root? How much does it weigh about 300 meters? How much does it cost?

- The weight is 0.395 kilograms / meter by the theory. Can be rolled, is not the foot, the largest is 7.5 diameter, the price depends on the place, and the price is different from place to place

- Q: Can steel round bars be used for making fuel system components?

- Yes, steel round bars can be used for making fuel system components. Steel is a common material used in the manufacturing of various fuel system components due to its strength, durability, and resistance to corrosion. Steel round bars can be machined, welded, and formed into different shapes and sizes, making them suitable for a wide range of fuel system applications. Additionally, steel's high melting point and ability to withstand high pressure and temperature conditions make it a reliable choice for fuel system components that are exposed to extreme conditions.

- Q: What are the common sizes of steel round bars?

- The common sizes of steel round bars vary, but some frequently used diameters range from 1/4 inch to 12 inches.

- Q: Are steel round bars suitable for the production of axles?

- Indeed, axles can be produced using steel round bars. Steel, being a robust and long-lasting material, offers exceptional strength and stability, rendering it an optimal selection for axles. The circular form of these bars facilitates effortless machining and shaping processes, guaranteeing an accurate and efficient axle design. Moreover, steel round bars possess commendable resistance against wear, fatigue, and impact, indispensable attributes for axles that must endure demanding loads and harsh environments. All in all, steel round bars are a dependable and extensively employed material in diverse industries, including automotive, manufacturing, and construction, for axle production.

- Q: Are steel round bars suitable for use in the construction of bridges?

- Indeed, steel round bars prove to be a suitable choice for the construction of bridges. Offering a multitude of advantages, they are an ideal option for such projects. To begin with, steel round bars exhibit remarkable tensile strength, enabling them to withstand substantial loads and forces without undergoing deformation or breakage. This attribute holds paramount importance for bridges, as they bear the weight of vehicles and pedestrians. By possessing high tensile strength, steel round bars ensure the structural integrity and safety of the bridge. Furthermore, steel round bars boast exceptional durability and resistance to corrosion. Considering the exposure of bridges to adverse environmental conditions like rain, snow, and saltwater, materials employed in their construction are susceptible to corrosion and deterioration. However, steel round bars are specifically designed to counteract these effects, guaranteeing the longevity and dependability of the bridge. Moreover, steel round bars are widely available in various sizes and lengths, catering to the versatility and adaptability required for different bridge designs and configurations. The uniform circular shape of these bars simplifies the construction process, enabling easy cutting, bending, and welding to meet the necessary specifications. In addition, steel round bars offer cost-effectiveness in bridge construction. Their favorable strength-to-weight ratio allows them to provide the required strength while minimizing the overall weight of the bridge. Consequently, this reduces the amount of material needed and lowers transportation costs during construction. In conclusion, steel round bars are highly suitable for bridge construction due to their high tensile strength, durability, corrosion resistance, versatility, and cost-effectiveness. They deliver the necessary strength and reliability to support heavy loads and withstand adverse environmental conditions, ensuring the safety and durability of the bridge.

- Q: What are the advantages of using cobalt-alloy steel round bars?

- There are several advantages to using cobalt-alloy steel round bars in various industries and applications. Firstly, cobalt-alloy steel has exceptional strength and hardness, making it highly resistant to wear, corrosion, and high temperatures. This makes it suitable for demanding environments where other materials would fail or degrade quickly. Secondly, cobalt-alloy steel has excellent dimensional stability, meaning it maintains its shape and size even under extreme conditions. This makes it ideal for applications that require precise tolerances and minimal deformation, such as in the aerospace and automotive industries. Additionally, cobalt-alloy steel has excellent heat resistance, allowing it to retain its mechanical properties even at elevated temperatures. This makes it valuable in applications that involve high-speed machining, cutting tools, and turbine components. Moreover, cobalt-alloy steel round bars can be easily machined and fabricated, allowing for customization and versatility in various applications. Their high machinability and weldability make them suitable for use in manufacturing processes, such as forging, casting, and machining. Furthermore, cobalt-alloy steel round bars have excellent fatigue resistance, ensuring long-lasting performance and durability. This makes them suitable for applications that involve repetitive stress or cyclic loading, such as shafts, springs, and fasteners. Lastly, cobalt-alloy steel is known for its biocompatibility, making it suitable for medical and dental applications. It is commonly used in orthopedic implants, surgical tools, and dental instruments due to its corrosion resistance and biocompatibility properties. In summary, the advantages of using cobalt-alloy steel round bars include exceptional strength, hardness, and dimensional stability, as well as heat resistance, machinability, fatigue resistance, and biocompatibility. These qualities make them valuable in a wide range of industries and applications, offering reliability, durability, and performance.

- Q: What is the difference between a cold-drawn and a polished steel round bar?

- The manufacturing processes and resulting properties of a cold-drawn steel round bar and a polished steel round bar are different. To produce a cold-drawn steel round bar, a hot-rolled steel bar is pulled or drawn through a die or series of dies at room temperature. This reduces its diameter and increases its length. This process imparts specific characteristics to the steel. Cold-drawn steel bars have a smooth and shiny surface, with tight dimensional tolerances and improved mechanical properties. The cold drawing process refines the microstructure of the steel, making it stronger, more uniform, and less prone to defects. These bars are commonly used in applications that require high strength, precision, and resistance to fatigue, such as automotive components, machinery, and tooling. In contrast, a polished steel round bar undergoes a different treatment process. Once the steel bar is formed, it undergoes polishing, which involves grinding or buffing the surface to achieve a smooth and reflective finish. Polished steel bars have a shiny and mirror-like appearance due to the removal of surface imperfections and contaminants. This process is primarily done for aesthetic purposes and does not significantly alter the mechanical properties of the steel. Polished steel round bars are commonly used in decorative applications, architectural designs, and furniture. In conclusion, the main distinction between a cold-drawn and a polished steel round bar lies in their manufacturing processes and intended applications. Cold-drawn bars go through a precise cold drawing process to enhance their mechanical properties, while polished bars undergo surface polishing for an aesthetically pleasing finish.

- Q: What is the typical tolerance for diameter and length in steel round bars?

- The tolerance for diameter and length in steel round bars can vary depending on the industry standards and requirements specific to each sector. Generally, the tolerance for diameter in steel round bars is typically between +/- 0.005 and 0.010 inches. This means that the bar's actual diameter can deviate up to 0.010 inches from the specified diameter, either larger or smaller. Likewise, the tolerance for length in steel round bars is usually around +/- 0.125 to 0.250 inches. Consequently, the actual length of the bar can differ up to 0.250 inches from the specified length, either longer or shorter. It is essential to highlight that these tolerances can differ based on the intended application and the manufacturing industry's specific standards. Therefore, it is vital to refer to the relevant industry standards or the manufacturer's specifications to determine the precise tolerances required for a specific steel round bar.

- Q: Can steel round bars be used in the manufacturing of couplings?

- The manufacturing of couplings can indeed make use of steel round bars. Steel round bars find widespread usage in a variety of industrial applications owing to their strength, durability, and versatility. When it comes to couplings, these are mechanical devices employed for connecting two shafts, either for power transmission or to accommodate the misalignment of the shafts. There exist diverse types of couplings, such as rigid couplings, flexible couplings, or universal couplings, each of which can be fabricated by machining, forming, or welding steel round bars. By utilizing steel round bars in the production process, the resulting couplings possess exceptional tensile strength, enabling them to endure heavy loads and torque. Moreover, steel round bars can be subjected to heat treatment, thereby augmenting their mechanical properties and rendering them suitable for an array of operating conditions and environments. Consequently, steel round bars hold considerable popularity as a preferred choice for the manufacturing of couplings.

- Q: Can steel round bars be used for making kitchen utensils?

- Kitchen utensils can indeed be made using steel round bars. Steel, being a robust and long-lasting material, is frequently employed in the manufacturing of kitchen utensils because of its ability to withstand corrosion, heat, and chemical harm. By effortlessly shaping and molding steel round bars, they can be transformed into a variety of utensils like spoons, forks, knives, and ladles. Moreover, steel utensils are non-reactive, ensuring that they do not release any harmful substances into food, thereby offering a safe option for cooking and food preparation.

Send your message to us

18KG/M Stainless steel billet for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords