10.75in TitanShield Casing, 13.84mm WT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

9.625" CO₂ Injection Casing

CCUS Specialist: Handles 10,000ppm CO₂ environments

Tech Edge:

Internal Cladding: 1.0mm Inconel 625 layer

pH Resistance: 3.5-11.0

Expansion Joints: Accommodate 1.2% volume changes

Real-World Use:

At Norway's Sleipner CCS project, these casings maintained integrity through 50+ injection cycles over 8 years.

Key Specs:

Max OD: 244.5mm (9.625")

Pressure: 6,000psi working pressure

Coupling: Tapered trapezoidal thread

Offer: Free CO₂ corrosion calculator + 15-year performance guarantee

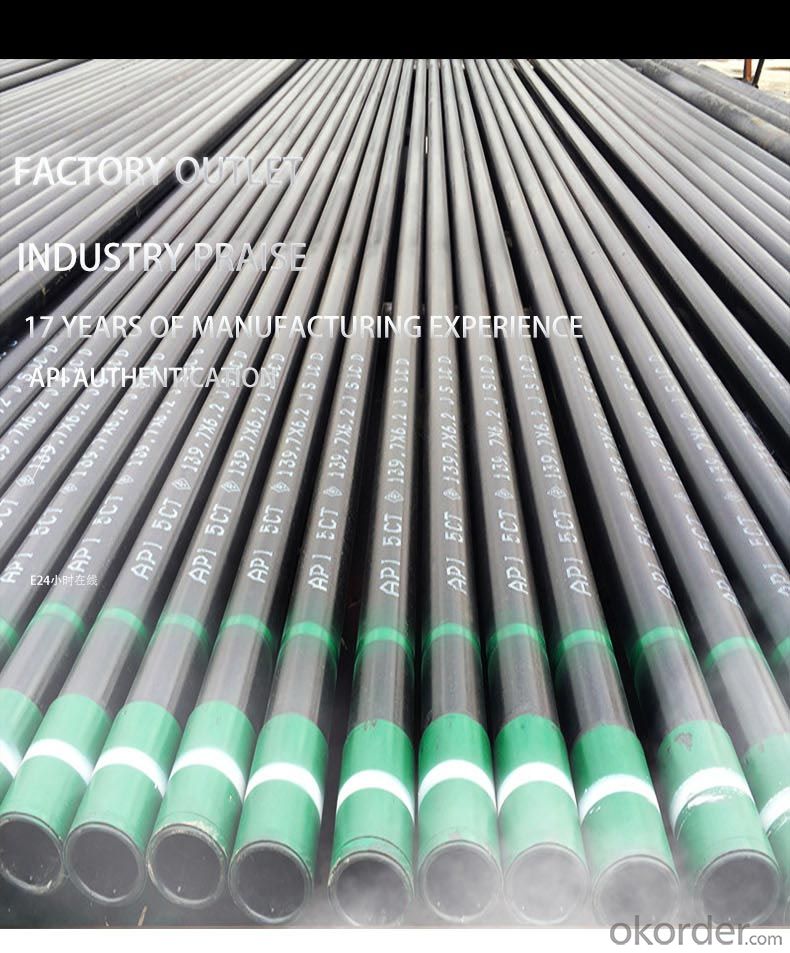

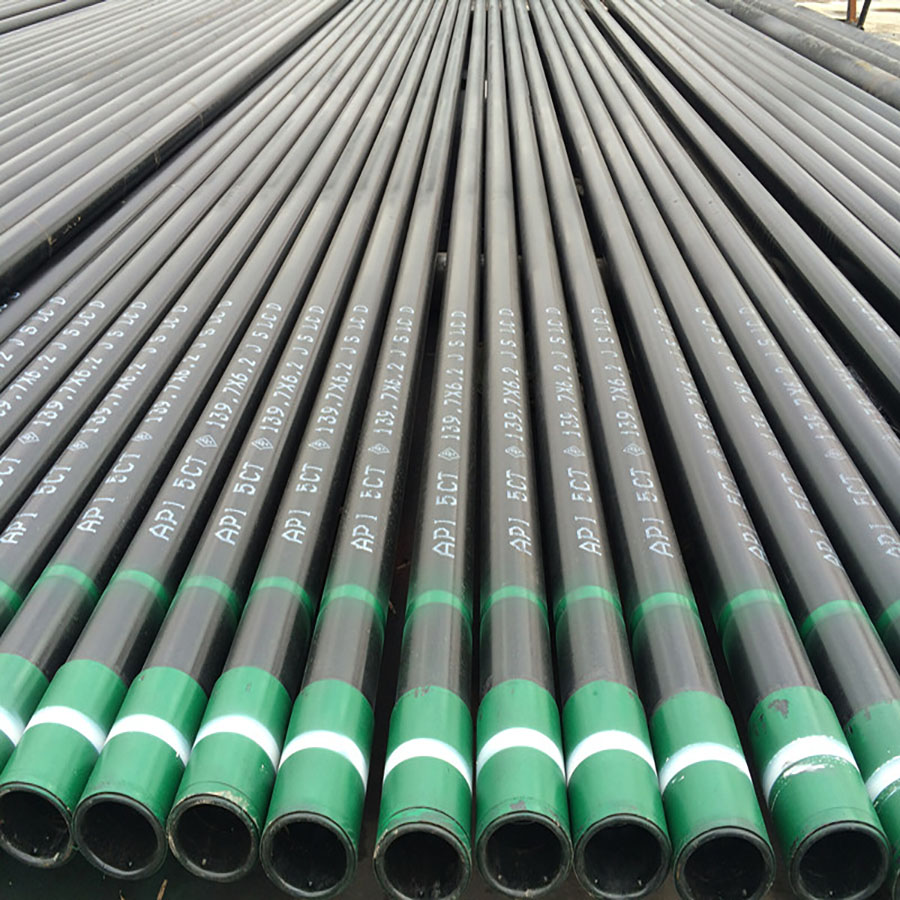

Petroleum Casing Product Information

1. Product Overview

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

2. Technical Specifications

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

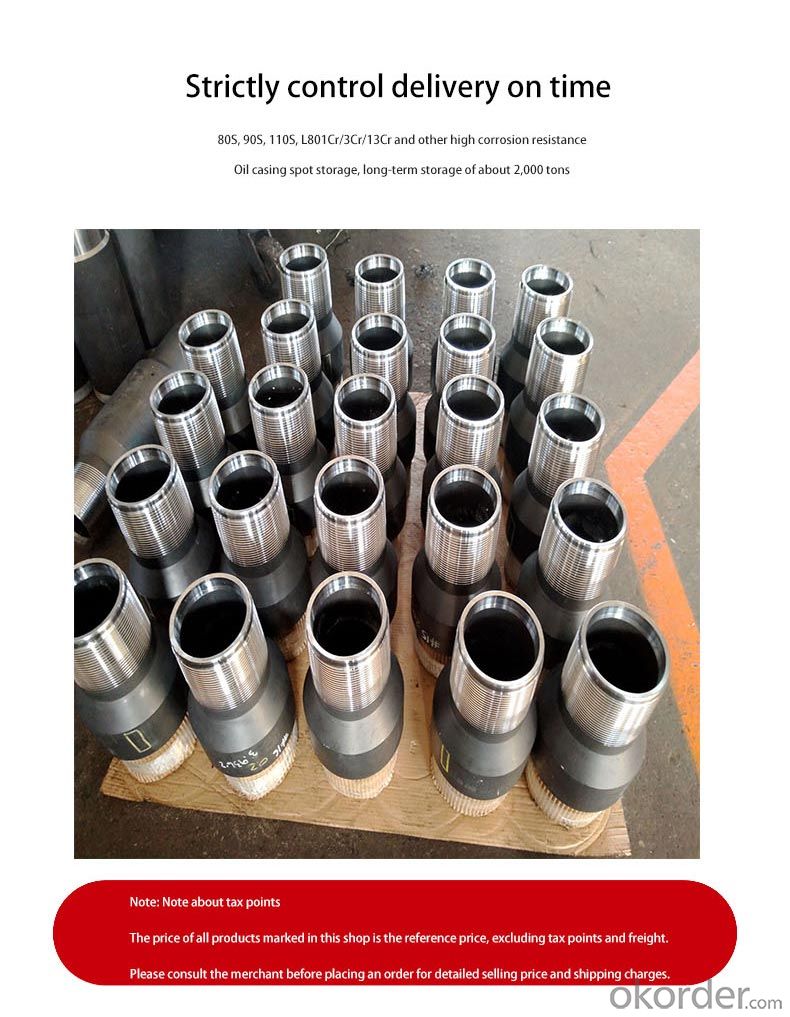

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

3. Chemical Composition (Example: L80 Grade)

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

4. Application Scenarios

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

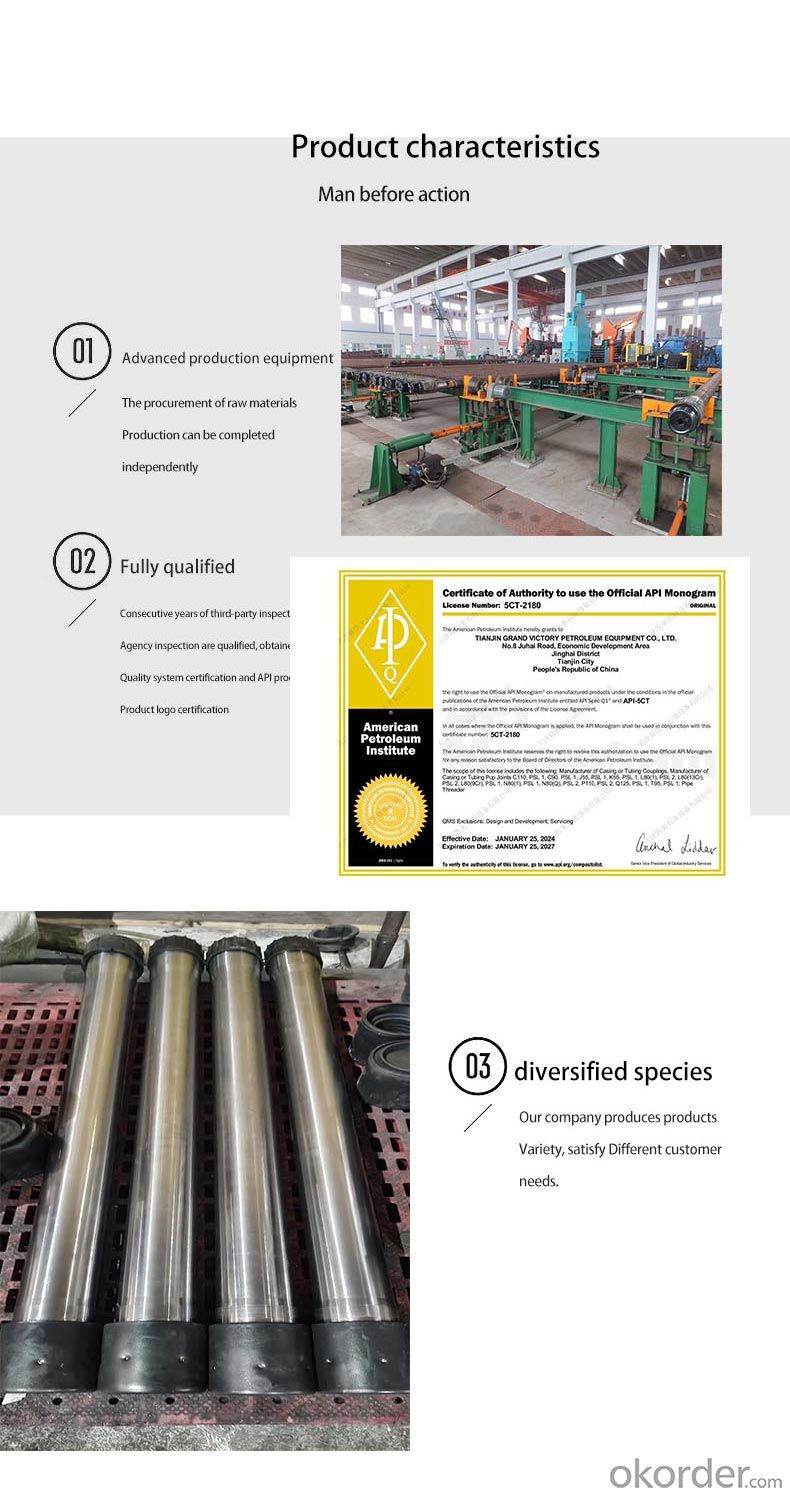

5. Production Process

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

- Q: How are steel pipes tested for mechanical strength?

- Steel pipes are tested for mechanical strength through various methods such as tensile testing, hydrostatic testing, and non-destructive testing. Tensile testing involves pulling the pipe until it breaks to measure its ultimate tensile strength. Hydrostatic testing involves pressurizing the pipe with water to check its ability to withstand high internal pressures. Non-destructive testing methods like ultrasonic testing or magnetic particle inspection are also used to detect any defects or weaknesses in the pipe without causing damage. These tests ensure that steel pipes are strong enough to withstand the required mechanical stresses.

- Q: How are steel pipes used in the manufacturing of heat exchangers?

- Steel pipes are commonly used in the manufacturing of heat exchangers due to their strength, durability, and ability to withstand high temperatures and pressures. These pipes are typically used to create the primary heat transfer surfaces within the heat exchanger, allowing for efficient transfer of heat between two fluids. The steel pipes are often arranged in a coil or tube bundle configuration, providing a large surface area for heat exchange to occur. Additionally, the corrosion-resistant properties of steel make it an ideal choice for handling various fluids in heat exchanger applications.

- Q: How are steel pipes used in the manufacturing of appliances?

- Steel pipes are commonly used in the manufacturing of appliances as they are strong, durable, and resistant to corrosion. These pipes are used for various purposes such as supply and distribution of water, gas, and other fluids, as well as for structural support and framework in appliances. They are often used for creating the internal plumbing systems, ventilation ducts, and electrical conduits in appliances, ensuring efficient functioning and reliability.

- Q: How are steel pipes protected against seismic activities?

- Steel pipes are protected against seismic activities through various measures. One common method is the use of seismic restraint systems, which include bracing, clamps, and supports that are designed to withstand the forces generated during an earthquake. Additionally, pipes can be coated with corrosion-resistant materials to enhance their durability and resistance to seismic events. Regular inspection and maintenance of the pipes are also essential to ensure their continued protection against seismic activities.

- Q: How are steel pipes protected from corrosion in corrosive environments?

- Steel pipes are protected from corrosion in corrosive environments through various methods such as applying protective coatings, using cathodic protection, and employing corrosion inhibitors.

- Q: What is the buckling type thin-wall steel pipe? What is a tight set of thin-walled steel tubes? What's the difference between the two?

- The wire pipe thread (box, cup lock fastening points) (JDG) and buckling type (KBG) two. Products are made of high-quality steel pipe, through precise stamping molding, supply pipe and terminal box connection. The nut is hexagonal, and the convex point is punched at the six corner so as to form a good multi-point contact after being connected with the junction box.

- Q: How are steel pipes coated to prevent internal corrosion?

- Steel pipes are coated to prevent internal corrosion by applying a protective layer or coating, such as epoxy or polyethylene, on the inner surface of the pipes. This coating acts as a barrier, preventing contact between the steel and corrosive substances in the fluid being transported, thereby reducing the risk of corrosion.

- Q: How are steel pipes used in the food and beverage industry?

- Steel pipes are commonly used in the food and beverage industry for various applications such as transporting liquids and gases, including water, beverages, and food ingredients. They are chosen for their durability, resistance to corrosion, and ability to maintain hygiene standards. Steel pipes are used to facilitate the flow of materials throughout the production process, ensuring safe and efficient operations in the food and beverage industry.

- Q: What are the common maintenance practices for steel pipes?

- Common maintenance practices for steel pipes include regular inspections, cleaning, and corrosion prevention. Regular inspections are crucial to identify any signs of damage or wear. This can involve visual inspections, as well as non-destructive testing methods such as ultrasonic testing or magnetic particle inspection. Inspections should be carried out on a scheduled basis to ensure any issues are detected early on and can be addressed promptly. Cleaning is another important maintenance practice for steel pipes. This involves removing any dirt, debris, or scale that may accumulate both on the inside and outside of the pipes. Regular cleaning helps to prevent blockages, improve flow efficiency, and reduce the risk of corrosion. Corrosion prevention is a key aspect of maintaining steel pipes. Various methods can be employed to protect the pipes from corrosion, such as applying protective coatings, using cathodic protection systems, or implementing corrosion inhibitors. These measures help to extend the lifespan of the pipes and ensure their structural integrity over time. Other maintenance practices may include repairing or replacing damaged sections of the pipes, maintaining proper insulation to prevent heat loss or gain, and monitoring the pipes for any signs of leakage or pressure drops. Overall, regular inspections, cleaning, and corrosion prevention are essential maintenance practices for steel pipes. By implementing these practices, the lifespan of the pipes can be prolonged, and potential issues can be identified and addressed before they cause significant damage or disruptions.

- Q: What are the factors to consider when selecting steel pipes?

- Some factors to consider when selecting steel pipes include the intended application and environment, the required strength and durability, the size and thickness of the pipes, the corrosion resistance, the cost, and the availability of different types of steel pipes.

Send your message to us

10.75in TitanShield Casing, 13.84mm WT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords