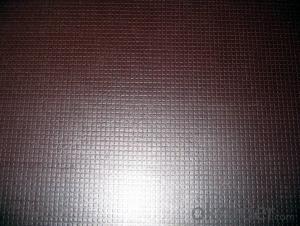

1 Inch Okume Face and Back Block Board for Packing Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Okume face and back Block Block are widely used in construction, furniture, Decoration, especially for packing.

Characters:

Light, easy to install and disassemble; less glue, more environmental.

Products Details:

Detailed Specification:

Product name: Block Board

Size:1220*2440 or as requested

Thickness: 12/15/18/21mm

Core: Poplar/Hardwood/ Mixed Core or etc

Glue: Mr/ E2

Face & Back: Poplar/Okoume/BintangorSapelli/ Pencil cedar/Birch etc

Grade: BB/BB, BB/CC, C+/C

Density: 460-720KGS

Certificate: CE/ISO/FORM A&E

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP CNT-----8PLTS/22M3/15TONS

40’GP CNT----16PLTS/44M3/23TONS

40’HQ CNT----18PLTS/55M3/28TONS

Train: 48PLTS/110M3/60Tons/Train

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.What’s the raw material of Blockboard?

A1: Main raw materials are poplar core, falcata core, pine core or Paulownia core.

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: defects are divided into four grades

- Appearance grade: ordinary plywood according to the processing of plywood can be seen on the material defects

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: Plywood can improve timber utilization and is a major way to save wood.

- Pure solid wood furniture is that all the furniture materials are solid wood, including the desktop, wardrobe doors,

- Q: How do you choose plywood in plywood production?

- Several kinds of said in the "veneer", "slices", "veneer" are reflected in the "plaque" the basic characteristics. But can not be cedar plywood, ash willow plywood and other abbreviations, because these referred to as refers to the plywood panel, the floor by the cedar or Ash made.

- Q: What plywood is now commonly used?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Multilayer board and plywood difference

- A group of boards are usually made of mutually adjacent panels in the direction of the adjacent layers.

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Why is the plywood commonly used in the singular layer

- This is a good understanding of the regardless of the plywood and plywood they are for the sake of their each of them are vertical lines of the

- Q: The basic principle of plywood

- but the symmetrical center plane in any two layers of symmetrical veneer on both sides and the same thickness. The panel does not allow the same species.

Send your message to us

1 Inch Okume Face and Back Block Board for Packing Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords