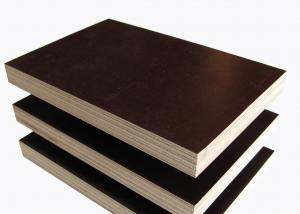

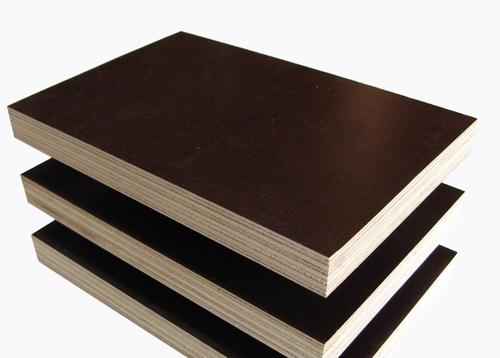

1/2 Birch Plywood - 18mm Film Faced Plywood, MR/Melamine WBP Glue Film Faced Plywood, Poplar Core/Hardwood Core Shuttering Plywood for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

uick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| Size: | Thickness: | Core: | |||

| Color of film: | Tensile adhesion: | Bending Strength: | |||

| Compressive Strengt: | Compressive Strength: | Warp: |

Packaging & Delivery

| Packaging Detail: | Inner packing: inside pallet is covered with 0.2mm plastic bag Outer packing: by pallet, wrapped in carton, reinforced with iron belt |

| Delivery Detail: | 15Days |

Specifications

film faced plywood

1 waterproof

2 UV capability not easily fade

3 Anti-scratch, anti-acid alkali

4 Environmentally, E1 gra

610*2500*20mm film faced plywood manufacturers,marine plywood

Specifications

1. More than 12 years production experience

2. More than 8 years export experience

3. Excellent after-sell service

1. Big Size: The biggest size is 2440*1220mm, 915*1830 mm, which could decrease the numbers of the joint and increase the working efficiency. And the planking will not deform and crack, it can resist water well, re-use many times and demoulds easily.

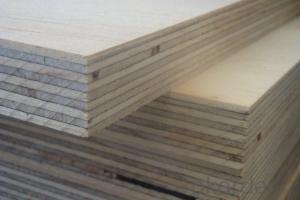

2. Light weight: It is more suitable for high-rise building and bridge construction.

3. Re-use number: For Melamine glue, usually can be used about 8 times, and for WBP glue, can be re-using above 15 times.

4. Concrete building: It can keep the surface smooth and beautiful when used for pouring, and you don’t need to plaster the wall for second time, for it can decorate directly that will decrease the construction period by 30%.

5. Corrosion resistance: It will not pollute the surface of the concrete.

6. Good moisture-retention: It is good for construction, and in winter it can be used as template for curved surface.

7. Good workability: It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling, it can be processed to template with all shapes according to needs.

Product advertage:

1.The transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2.It is good to keep surface warm so in winter the project can also be continued.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4. The film faced plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5.Environmentally friendly.

6.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

- Q: What is the general use of plywood in decoration works?

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Selection of plywood in plywood production

- Artificial veneer is the use of relatively low prices of logs cut into veneer, made by a certain process pressure made of wood, and then cut into a beautiful pattern decorated veneer.

- Q: Plywood can improve timber utilization and is a major way to save wood.

- side panels are made of pure solid wood, do not use any other form of wood-based panels

- Q: Further processing of the plywood

- plywood treated plywood plywood used in the manufacturing process or after manufacturing to deal with the physical properties of coupons.

- Q: The Preparation of plywood ingredients

- veneer veneer mountain peeling, semi-circular peeling, slicing or sawing the production of flakes of wood.

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: Hard fiber board is also a density board

- , the same tree species or similar tree species, the same processing method (peeling or slicing)

- Q: What is the plywood made of wood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: For the plywood environmental advice?

- E0 is the highest environmental rating. E1 grade glue to do the plywood can be used directly for the interior.

Send your message to us

1/2 Birch Plywood - 18mm Film Faced Plywood, MR/Melamine WBP Glue Film Faced Plywood, Poplar Core/Hardwood Core Shuttering Plywood for Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords