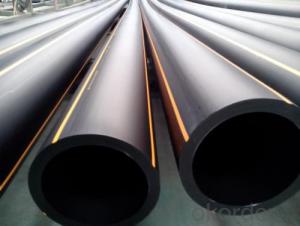

0.4MPa/0.4MPa/0.6MPa/1.0MPa PE pipe for gas pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Name: polyethylene pipes for gas supply

Standard: GB 15558.1-2003

Nominal Pressure: 0.4MPa/0.4MPa/0.6MPa/1.0MPa

Nominal Diameter: 16mm-630mm

Wall Thickness: 2.3mm-57.3mm

PE pipe for gas pipe

Product Name: polyethylene pipes for gas supply

PE gas pipe is made of PE80 and PE100 to be produced by extrusion molding ,suitable for operating at temperature of -20℃~40℃.According to production and testing requirements of national standards GB15558.1-2003 (Gas buried polyethylene pipe) ,wall thickness can be divided into: SDR11 and SDR17.6.SDR11 series for transporting artificial gas, natural gas, liquefied gas;SDR17.6 series for transporting natural gas;nominal diameter of DN16-DN630mm.

Features of PE gas pipe:

PE gas pipeline has many excellent features, such as corrosion resistance, toughness, hardness and softness;also reflects the excellent performancein some special applications . For example,polyethylene pipe has solved corrossion and leakage presence of the traditional steel pipe fittings , and low cost. In addition, the outdoor line and pipeline is laying in the corrosive soil or in the earthquake zone, mountainous and swampy areas .

Main advantages

(1) corrosion resistance

Polyethylene is an inert material, except for a few strong oxidant, can be resistant to a variety of chemical media. No electrochemical corrosion, no coating.

(2) does not leak

Polyethylene pipe use mainly hot melt connection or fused connection,to achieve integration between joint and tubing. Compared with the rubber ring joints or other mechanical joints, because there is not dangerous that joint distortion causes leakage.

(3) High toughness

The elongation at break generally over 50%. excellent seismic performance had become proved in Wenchuan earthquake.

(4) PE pipe has excellent flexibility to be coiled.

Longer length supply without the need for a variety of connection fittings.

(5) good anti-scratch ability

Ability to resist scratches and slow crack growth (SCG) is close.Studies have shown, PE80 gas pipe has better ability and resistance to scratches . PE100 gas pipe have a better ability to resist ing scratches.

(6) Excellent resistance to rapid crack pass.

(7) Long service life up to 50 years

(8) good impact resistance, heavy directly pressure through the pipe will not cause pipeline rupture.

(9) compared with steel, cast iron pipe and steel mesh composite pipe , convenient construction and lower total cost.

Application:

1. Gas Transportation

2. Liquied gas transportation

3. artificial gas transport

4. Industrial gas

5. Industrial corrosive liquid feed delivery

Physcial performance of PE gas pipe

number | item | requirement | test standard | |

1 | long-term hydrostatic strength,Mpa(20℃,50 year,95%) | ≥8.0 | GB15558.1-2003 | |

2 | short-term hydrostatic strength Mpa | 20℃ | ductile failure time 9.0 (h)≥100 | |

80℃ | brittle failure time 4.5 (h)≥165 | |||

Failure time 4.0(h)≥1000 | ||||

3 | thermal stadility(200℃),min | >20 | ||

4 | resistance to stress cracking, h(80℃,4MGpa) | ≥1000 | ||

≥170 | ||||

5 | compression recovery(80℃,4MGpa) | >170 | ||

6 | Longitudinal reversion rate(110℃),% | ≤3 | ||

7 | Elongation at break% | ≥350 | ||

8 | weathering (accumulation pipe by ≥3.5KMJ / m after aging energy) | still meet the performance requirements of 2.3.7, and maintain good weldability | ||

Note: for working temperature -20 ℃ -40 ℃, the maximum working pressure ≤0.4Mpa artificial coal gas and natural gas, liquefied petroleum gas. | ||||

Specification:

nominal outside diameter (mm) | PE80 | PE100 | ||

SDR17.6(≦0.2MPa) | SDR11(≦0.4MPa) | SDR17.6(≦0.6MPa) | SDR11(≦1.0MPa) | |

wall thickness (mm) | wall thickness (mm) | wall thickness (mm) | wall thickness (mm) | |

16 | 2.3 | 3.0 | 2.3 | 3.0 |

20 | 2.3 | 3.0 | 2.3 | 3.0 |

25 | 2.3 | 3.0 | 2.3 | 3.0 |

32 | 2.3 | 3.0 | 2.3 | 3.0 |

40 | 2.3 | 3.7 | 2.3 | 3.7 |

50 | 2.9 | 4.6 | 2.9 | 4.6 |

63 | 3.6 | 5.8 | 3.6 | 5.8 |

75 | 4.3 | 6.8 | 4.3 | 6.8 |

90 | 5.2 | 8.2 | 5.2 | 8.2 |

110 | 6.3 | 10.0 | 6.3 | 10.0 |

125 | 7.1 | 11.4 | 7.1 | 11.4 |

140 | 8.0 | 12.7 | 8.0 | 12.7 |

160 | 9.1 | 14.6 | 9.1 | 14.6 |

200 | 11.4 | 18.2 | 11.4 | 18.2 |

225 | 12.8 | 20.5 | 12.8 | 20.5 |

250 | 14.2 | 22.7 | 14.2 | 22.7 |

280 | 15.9 | 25.4 | 15.9 | 25.4 |

315 | 17.9 | 28.6 | 17.9 | 28.6 |

355 | 20.2 | 32.3 | 20.2 | 32.3 |

400 | 22.8 | 36.4 | 22.8 | 36.4 |

450 | 25.6 | 40.9 | 25.6 | 40.9 |

500 | 28.4 | 45.5 | 28.4 | 45.5 |

560 | 31.9 | 50.9 | 31.9 | 50.9 |

630 | 35.8 | 57.3 | 35.8 | 57.3 |

- Q: Hose wire is it? What's the function?

- Such as suction hose, spiral steel wire in addition to play a part of the enhanced pressure role, mainly from the role of vacuum pumping; second is mainly to enhance the role of pressure, such as steel wire braided hose / steel wire winding hose.

- Q: What are the matters that should be paid attention to when installing rubber hose joint in water pump?

- Know the rubber pipe joint is also called rubber joints, with vibration and noise reduction effect in the pipeline, and if used in water pump, so its main function is to prevent the suction flat and bear short time pressure, avoid water pump power and vibration and suction pipe bottom swing, the uniform flow and promotion in addition, the pump power consumption is reduced, because the rubber joint wall vertical groove, and prevent the vortex pump water, thereby improving the efficiency of water pump.

- Q: Three yuan ethylene propylene rubber tube covered with nylon PA66, what glue can not afford the layer?

- Rubber and nylon 66 composite needs special treatment, high temperature vulcanization will not rise layer, we can wait for production, need to produce details, Baidu search: rubber technology, Li Yuan studio.

- Q: Production process and raw material of rubber

- Raw materials: all kinds of rubber, rubber compounding agent, as well as the fiber and metal skeleton materials.

- Q: Petroleum gas has a corrosive effect on ordinary rubber pipes and is easy to cause air leakage. So, what kind of hose must be used?

- In order to remind people of the leakage of liquefied petroleum gas in a timely manner, the processing plant often mixes a small amount of foul odor mercaptan or thioether compounds into liquefied petroleum gas, which is the source of special odor.

- Q: Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: Stainless steel metal hose and flexible rubber joint which is easy to use?

- Stainless steel metal hoses and flexible rubber couplings are used for pump inlet and outlet to absorb vibration and noise during the operation of the pipe pump. The two products are common in the case of ordinary media.

- Q: What are the types of hose connectors?

- Joint classification of common are: expansion joints, quick couplings, withhold joints, removable fittings, compression fittings, flared joint is in welded joints.

- Q: What are the pipes in the air conditioner?

- General automotive air conditioning work principle: compressor exhaust, condenser, liquid storage dryer, expansion valve, evaporator, compressor suctionEach of the arrows (except the expansion valve to the evaporator) represents an air conditioning line. Some of them are rubber tubes and some are made of metal tubes.

- Q: How should we distinguish between the silicone hose and the rubber tube?

- Silicone hose is relatively soft, flexible, and looks better than other rubber tube gloss, color is mostly red, blue, translucent and other colors. Others, such as three yuan ethylene propylene and nitrile rubber hose, are basically black.

Send your message to us

0.4MPa/0.4MPa/0.6MPa/1.0MPa PE pipe for gas pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords