0.4mm 1050 1060 3003 thin aluminum strip is suitable for blinds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Blinds are a kind of soft decoration for new homes. Now new buildings are basically used for decoration. "Aluminum alloy blinds" are a widely used type of curtains, made in the shape of blinds. Aluminum alloy blinds are mainly made of aluminum alloys that are not easy to rust.

Commonly used aluminum strip alloys for blinds include 1050, 1060, 3003, 3004, 3104 and 5052. These alloys are widely used in blinds because they have good performance and applicability.

Performance advantages of aluminum strips for blinds:

1. Lightweight characteristics: easy to install, use and carry, reducing the burden on building structures.

2. Corrosion resistance: an aluminum oxide film is formed on the surface to effectively resist wind and rain erosion and oxidation corrosion.

3. Good processability: easy to process into various shapes and sizes to meet diverse design needs.

4. Aesthetics: The surface is smooth and shiny, with good decorative effect and supports personalized surface treatment.

Aluminum strip specifications:

| Alloy | 1050 1060 3003 5052 etc |

| Temper | H14, H24, H16, etc. |

| Thickness | 0.1-0.5mm |

| Width | Common widths are 16mm, 25mm, 50mm, etc. The specific size can be customized according to the specifications of the blinds. |

| Surface treatment: | (1) Anodizing: Improves corrosion resistance and increases color options. (2) Coating treatment: Apply weather-resistant paint to enhance decorativeness. (3) Brushed, frosted treatment: Provides a textured surface. |

| Quality | No rust, oil stains, rolling marks, edge damage, flaring, dents, holes, broken wires, scratches |

| Application | blinds, window curtains, etc. |

| Packaging | Export wooden pallets, kraft paper. |

| MOQ | 1-3 tons |

| Delivery time | 7-15 days after payment |

Application scenarios:

Aluminum strip blinds are widely used in various buildings and home environments, such as offices, residences, schools, hospitals, etc. They not only provide good shading and ventilation functions, but also increase the beauty and practicality of the building.

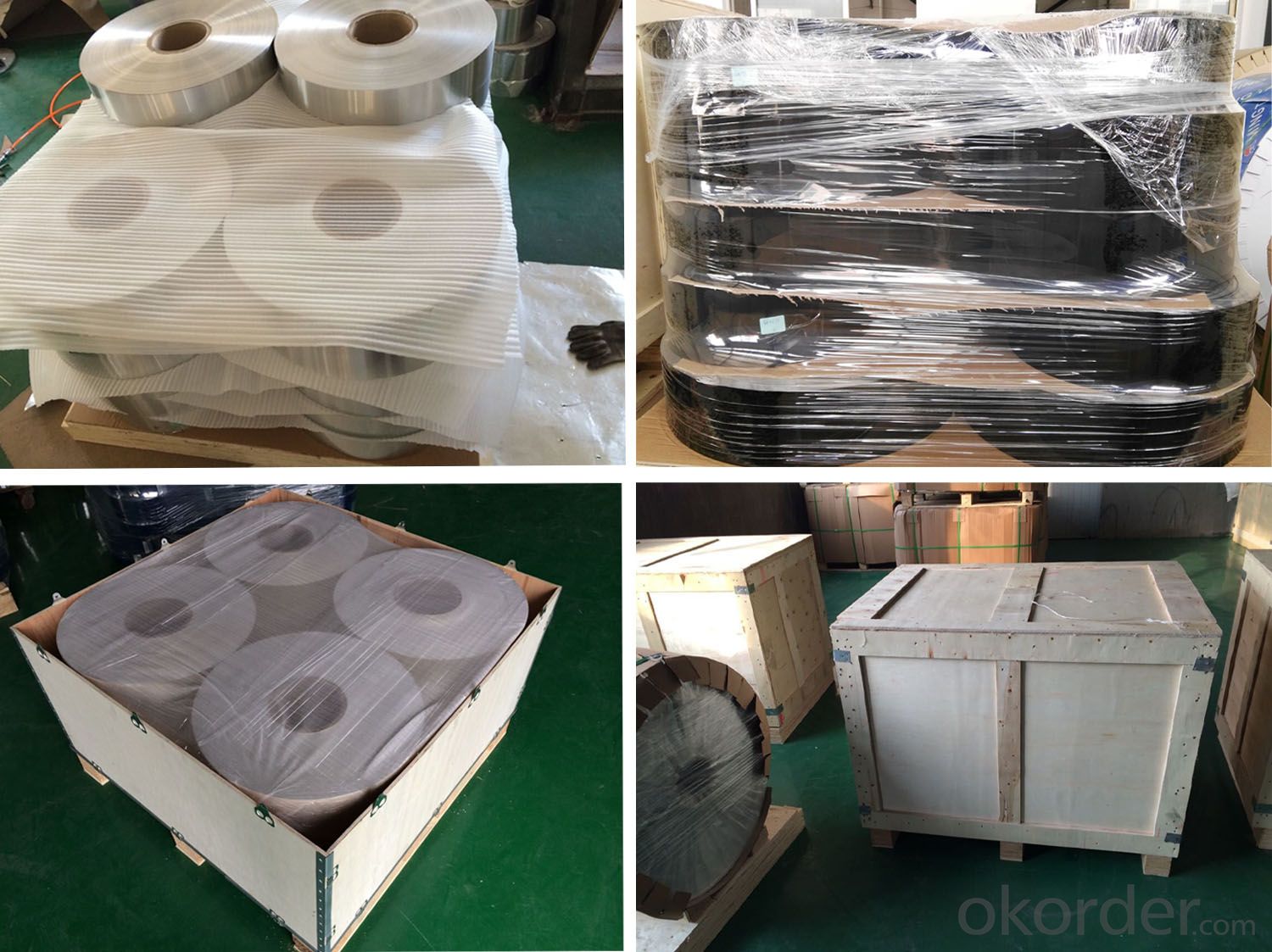

Packing:

(1) Standard seaborne export packaging, wooden pallets, with plastic protection coils and sheets;

(2) 15-20 tons can be loaded into a 20-foot container. We try to use 20-foot containers. The sea freight is much cheaper than 40-foot containers.

(3) Other packaging can be made according to customer requirements.

(4) The packaging is very strong, with 3 layers, thick fiber, foam, plastic. The bottom is a wooden pallet. You can see the detailed packaging information below.

FAQ:

Q1: How to ensure quality?

A1: Factory test certification is provided with shipment, third-party inspection can be provided

Q2. What are your company's main products?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, etc.

Q3: Where is your factory?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

Q5: How is your price?

A5: Our price is very competitive. If you are interested in our products, please feel free to contact us at sales @ alummc . com.

Aluminum strip products have a wide range of market uses. Our company has many types of equipment, including multiple longitudinal shearing equipment, complete equipment models, and products can cover all alloy series. The product supply forms are diverse and can meet all customer needs. The strip thickness of our company ranges from 0.08mm-10mm, and the width ranges from 12mm-2600mm, and coils are supplied.

- Q: This question asks for a step-by-step guide on how to measure and cut an aluminum strip to fit a specific project.

- <p>To measure and cut an aluminum strip for your project, first determine the required length and width. Use a measuring tape or ruler for precise dimensions. Mark the measurements on the strip with a marker. For cutting, use a hacksaw or a metal cutting saw for straight cuts. Ensure the strip is secured in a vise or clamped to prevent movement. Cut along the marked lines, and use metal files or sandpaper to smooth any rough edges. For curved cuts, use a jigsaw with a metal cutting blade. Always wear safety goggles and gloves to protect yourself from metal shards and sharp edges.</p>

- Q: Inquiring about the durability of aluminum strips.

- <p>Aluminum strips are known for their durability. They are resistant to corrosion and weathering, making them suitable for long-term use in various environments. Their strength and light weight also contribute to their durability, allowing them to withstand significant stress without breaking. However, their longevity can be affected by factors such as the quality of the aluminum, the manufacturing process, and the specific conditions they are exposed to. Proper maintenance and handling can further enhance their durability.</p>

- Q: Can the high frequency of aluminum band replace the high frequency of professional high-power loudspeaker box?

- The same volume, sound intensity, ribbon horn may have burned out, and horn speakers have not worked out.

- Q: Is there any risk associated with the use of aluminum strips for roofing and siding purposes?

- <p>While aluminum strips are generally safe for roofing and siding, there are a few concerns to consider. Aluminum can expand and contract with temperature changes, which may lead to buckling or warping over time. Additionally, it is a good conductor of heat and electricity, so it may not provide the best insulation or protection against lightning strikes. Aluminum is also prone to denting and can be noisy in heavy rain or hail. However, it is lightweight, durable, and resistant to corrosion, making it a popular choice for many homeowners. Proper installation and maintenance are crucial to minimize these risks.</p>

- Q: Can aluminum strips be recycled repeatedly without any loss in quality?

- <p>Yes, aluminum strips can be recycled indefinitely without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the metal's properties. In fact, recycled aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. This makes aluminum recycling an environmentally friendly and sustainable practice.</p>

- Q: Is it possible to use aluminum strips as a material for roofing purposes?

- <p>Yes, aluminum strips can be used for roofing. They are known for their durability, corrosion resistance, and lightweight properties, making them a popular choice for metal roofing. Aluminum roofing strips are low maintenance, energy-efficient, and can be recycled, offering environmental benefits. They are also resistant to harsh weather conditions and can last for several decades with proper installation and care.</p>

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: What are the various types of waterproofing materials that utilize aluminum strips in their composition?

- <p>Aluminum strips are used in several types of waterproofing materials due to their durability and resistance to corrosion. Some common types include: 1) Aluminum Foil Tapes: These are adhesive tapes with an aluminum foil backing, used for sealing joints and seams. 2) Aluminum Coated Fabrics: Fabrics coated with aluminum to provide a barrier against water and UV rays, often used in construction and roofing. 3) Aluminum Flashing: Sheets of aluminum used to cover joints and intersections in roofing and walls to prevent water infiltration. 4) Aluminum Waterproofing Membranes: These are flexible sheets that can be applied to surfaces to create a waterproof barrier. 5) Aluminum Coated Self-Adhesive Sheets: These are sheets with a self-adhesive backing and an aluminum coating, used for sealing and waterproofing applications. Each type serves specific waterproofing needs and is chosen based on the application and environmental conditions.</p>

- Q: What are the various classifications of aluminum strip based on their properties and applications?

- <p>Aluminum strips are classified into different grades based on their alloy composition, mechanical properties, and applications. Common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicium alloys). Each grade has specific characteristics, such as corrosion resistance, formability, and strength, making them suitable for various industries like construction, automotive, and packaging.</p>

- Q: How can the aluminium band be welded to the steel shell?

- If it is more than 0.5 mm by resistance heating welding, welding materials need to use the 303B welding wire Odin wei.Welding tools: carbon block welding, welding with two electrodes.

Send your message to us

0.4mm 1050 1060 3003 thin aluminum strip is suitable for blinds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords