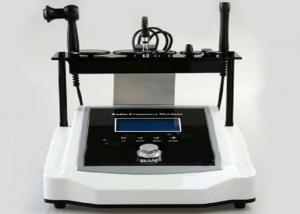

Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ultrasonic Plastic welder

1.quality, stable power output

2.make customized sonotrode

3.easy maintenance

4.adjustable base

Ultrasonic Plastic Welder from our factory

- Suitable for thermoplastics welding

- Can weld plastic + metal

- able to make customized sonotrode / welding mold for customers

Advantages of Ultrasonic Welding:

This technique is fast, efficient, non-contaminating and requires no consumables.

Features:

1.high quality air-drive mechanism & components

2.ceramic coated converter, ensure constant and powerful output

3.titanium alloy booster

4.adjustable base plate

5.Integrated design or Seperate design available

6.easy maintenance

7.Custom made is welcome

8.WE CAN MAKE CUSTOMIZED MOLD BASED ON CUSTOMER NEEDS

Specifications:

Model No. |

HN-1500 |

Ultrasonic Power |

1500W |

Ultrasonic Frequency |

20Khz |

Ultrasonic time |

0.1-5 seconds |

Welding Machine Dimension |

40 * 68 * 110 CM |

Ultrasonic Generator case |

38*54*14 CM |

Steel shelf |

have |

Net weight |

130 kg |

Power supply |

AC100V-120V, AC220V-240V |

We pride ourselves on supplying customers with high quality machines and offering technical knowledge and cleaning solutions. We also manufacture Automatic Welding systems.

Our factory is committed to doing most so that customers can meet business and operational requirements. Let our 18 years of experience work for you.

OTHER MODELS AVAILABLE FOR REFERNCE

Model |

HN-400 |

HN-800 |

HN-1200 |

HN-1500 |

HN-2000 |

Ultrasonic Power |

400W |

800W |

1200W |

1500W |

2000W |

Ultrasonic Frequency |

28/40 Khz |

28/40 Khz |

15/20 Khz |

15/20Khz |

15/20Khz |

Pneumatic Cylinder |

75 mm |

75 mm |

75mm |

75mm |

75mm |

Ultrasonic Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Stay Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Lingerin Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Power supply |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

How Ultrasonic Plastic Welders work:

Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

- Q:What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- Wuxi Nicle ultrasonic welding machine can also be ah. You can consult under specific circumstances

- Q:Ultrasonic plastic welding machine die is not durable, what material good?

- Titanium alloy will certainly be better. Just expensive.

- Q:What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- HelloBy ultrasonic Xiaobian for you to answer: the principle of ultrasonic plastic welding machine 20KHz is generated by the generator (or 15KHz) high voltage and high frequency signal, through changing systems, converts the signal into high frequency mechanical vibration on plastic workpieces,Through the surface of the workpiece and friction between molecules and the transfer to the interface temperature, when the temperature reaches the melting point of the workpiece itself, the interface is rapidly melting, and then fill in the gaps between the interface, when the motion stops, workpiece cooling under pressure at the same time, then achieve perfect welding.The hot melt machine adopts a pumping plate structure, and the heat of the heating plate is transferred to the welding surface of the upper and lower plastic heating parts by the electric heating method. The surface is melted, and the heating plate is rapidly exited, and the upper and the lower two heating elements are heated, and the fused surface is fused, solidified and integrated.Therefore, ultrasonic plastic welding machine through high-frequency mechanical vibration, friction heat generation plastic welding, and hot melt machine is heated by electric heating plastic softening welding

- Q:What's wrong with high ultrasonic plastic welding machines that have been overloaded?

- Do I have an ultrasound when overloaded?

- Q:What's the difference between metal welding machine and plastic welding machine?

- The difference is big, general welding metal welding machine is not welding blister, plastic can use high frequency welding machine welding;

- Q:Must be able to believe 8700AD ultrasonic plastic welding machine often appear failures and treatment methods?

- BRANSON 8700 imported from the United States, as long as the maintenance of good, nothing

- Q:What are the causes of the high power transistors in ultrasonic plastic welding machines?

- The driving signal drives the high power triode (IGBT) to work at high frequency (hard switching), which is susceptible to interference (mainly high-frequency)

- Q:Ultrasonic plastic welding machine die wave is not strong, how to repair?

- The gray section of the section (whether it looks like a powder after breaking) should be caused by excessive welding and possible causes:1, the welding time is too long, can be appropriate to reduce the delay time or welding time, welding speed or decrease;2, the machine power is too large, you can reduce gear, or choose a smaller power of the machine.If it feels that the wave is not strong, it can be modified as follows: reduce the total height, increase the frequency, and increase the waist height to reduce the frequency. But be careful not to drift out of the best total height.In addition, there may be a strong wave transfer mode is improper, as current mode without impaction, not adjusted to the best state.

- Q:For example: can PP and HDPE be soldered together? What's the strength?

- The same kind of material is easy to solder, PP melting point is higher, not easy to weld, try a good point

- Q:What are their differences? What are the manufacturers of high frequency welding machines?

- Plastic welding machine buy high frequency welding machine? Or ultrasonic plastic welding machine? Is based on their own products, requirements to determine, ultrasonic plastic welding machine is plastic, plastic welding, high-frequency machine is blister, 2 different products

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords