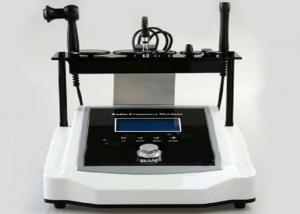

RF Skin Beauty Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit unit

- Supply Capability:

- 250 Units per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

RF Skin Beauty Machine

1.suitable for face and body skin

2.can work with different probes

3.Heads imported from Korea

4.Safe

RF Skin Beauty Machine from our factory, MODEL: L-28C

Features of Monopolar RF Machine

1. Rolling Electrode Type and oriented Pad Type available, aim at diffierent treating requirements.

2. Electronic digital control system: Adjust frequency and time, very simple and convenient.

3. Special design on RF heads: It equipps with different sizes of RF heads, suitable for face skin or body different parts.

4. Safety switch: it controls emergency pause to prevent overeating and inducint accidents.

5. Start form ‘Zero’: To prevent any possible accidents.

6. Inner Time Control: Treated time between 5 to 50 minutes, safe and free.

Technical Parameter:

Operating Frequency | 0.25-1Mhz |

Output Power | 300W |

Output current | 3A |

Net Weight | 4.25kg |

Gross Weight | 7.85kg |

Machine Dimensions | 850px*900px*450px |

Dimensions after Packaging | 1100px*1100px*875px |

- Q:What kind of hot air plastic welding torch and plastic welding machine made in China? Used to weld plastic sheets and tubing

- Wuxi Nicle ultrasonic welding machine can also be ah. You can consult under specific circumstances

- Q:Ultrasonic plastic welding machine power, the better the better?

- Welding products mainly depends on the size of your workpiece and welding results, not the bigger the better.

- Q:What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- Ultrasonic welding machine is to use high-frequency vibration to produce high temperature plastic welding. Hot plate welding is done by heating the tube directly against the heating of the plastic.

- Q:How many kinds of ultrasonic welding machine power are there?

- Is the power or frequency? Zhengzhou the Yellow River ultrasonic company has ultrasonic technology engineers, you ask him to ask, about the ultrasonic technology problems, he can answer you

- Q:What's wrong with high ultrasonic plastic welding machines that have been overloaded?

- Do I have an ultrasound when overloaded?

- Q:Please describe in detail the 2015 mould material manufacturing process, pay attention to the problem, the relevant difficult solution

- You may often have this idea: the welding head design and production is very simple. Don't be misled, when using an improper processing or without tuning of the welding head, will give you the production to bring expensive losses -- it will damage the welding effect, even more serious damage will directly lead to the transducer or the generator. So the design of the welding head like it's not as simple as that, on the contrary will need a lot of professional knowledge and skills, how to ensure the welding head can be the most economical work? How to ensure the welding head can be mechanical vibration transducer conversion can be effectively delivered to the workpiece, forming stable welding in Nicle ultrasonic, our engineers will each link are considered very full. Even if has several years of experience in the design and development, we still believe that only through the strict test and quality control to produce the best welding head. Through the analysis of the application as a finite element (FEM) of this process, our engineers will be acoustic properties and mechanical properties of the welding head of the perfect combination, design the products in line with customer needs. Each set of welding head and mould our production, whether standard products or customized according to customer requirements, are all made of the best materials and after repeated test. Welding head shape, intensity and audio etc. various parameters after many tests, can accord with the most stringent standards, welding head and mould achieve the most perfect match. Material is one of the main reasons to ensure the effect of ultrasonic mold life on welding products, and the process of mold completion is complicated. Therefore, not only the mold engineer design must carefully select material, but also need to understand its own product requirements, the use of what kind of material, avoid negligence and affect its timeliness and quality.

- Q:Must be able to believe 8700AD ultrasonic plastic welding machine often appear failures and treatment methods?

- I must be your dear brother.

- Q:What does ultrasonic plastic welding machine "15k20k" mean?

- Ultrasonic plastic welding machine 15k20k refers to the transducer working frequency is 15KHz, 20KHz. And the ultrasonic plastic welding machine also has 35KHz, 40KHz. The higher the relative frequency of ultrasonic plastic welding machine, the more expensive the price.15KHz ultrasonic plastic welder power can be divided into 2200W, 2600W, 3000W, 3200W, 4200W five kinds, 20KHz ultrasonic welding machine power 1200W, 1500W, 1800W, 2000W and so on.Ultrasonic plastic welding machine is widely used for traffic equipment industry, automobile industry, electronics industry, communications equipment industry, plastic industry, communication industry, medical industry, household appliances industry, non-woven clothing, stationery and office supplies, packaging and environmental protection industry, food industry, cosmetic industry, toy industry and other daily necessities.Equipment features of LH-2012F ultrasonic plastic welding machine:1 、 adopt the German PINOT original transducer, titanium alloy horn, the output power is large and stable, strong and durable, standard welding mode.2 、 Germany high-quality automatic shock constant balance circuit, automatic frequency tracking function.3, the design of the whole machine is smart, the German linear cross rail device, the chassis platform 4 point level design, very convenient operation.4 、 Japan man-machine interface, PLC control, control time accuracy up to 0.01 seconds. Chinese and English input operation, simple and convenient.5 、 Visual limit adjustment mode, convenient adjustment, high accuracy.6 、 visual fine tuning depth control mode design, cylinder, transducer three in one, direct drive, welding stability.7 、 this machine is specially used for welding precision microelectronic plastic workpieces.8, but also suitable for precision workpiece spot welding, riveting, embossing, dots and other welding processes.

- Q:Which brand is the best for ultrasonic plastic welding machine?

- To the collection of auxiliary equipment for plastic welding machine, plastic welding machine, the supply of a large number of users, different types of.

- Q:For example: can PP and HDPE be soldered together? What's the strength?

- No, PP can only be welded with PP. Pan ultrasound will be happy to answer it for you

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

RF Skin Beauty Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Unit unit

- Supply Capability:

- 250 Units per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches