Swing Check Valve Wafer Type Double PN 4 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

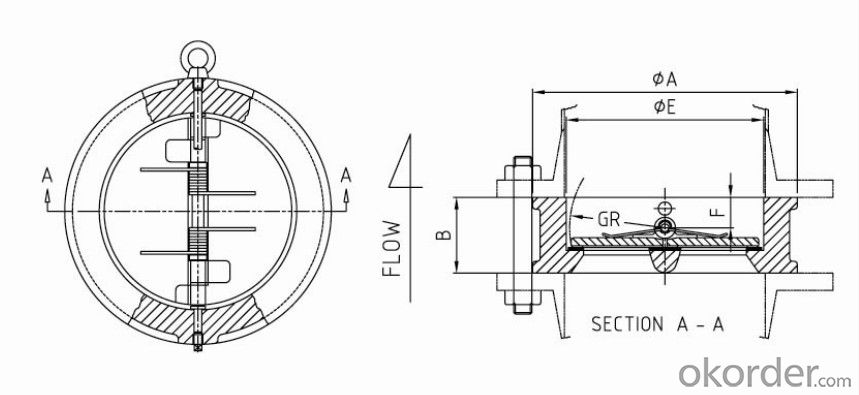

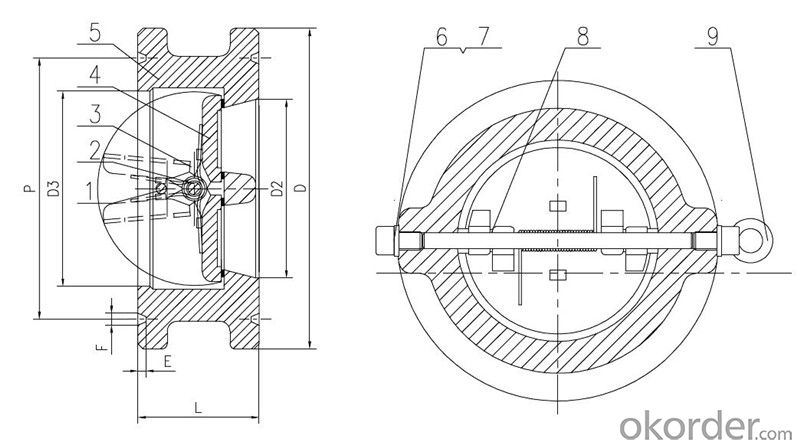

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:I recently converted my furnace from l.p. gas to natural gas. It's been maybe two weeks of me troubleshooting and replacing. I have a new gas valve and transformer in the furnace. There is 24v running to the valve and it clicks to open but no gas comes out. I have exhausted all my options with the mechanical/electrical components on the furnace. I have bled the valve to be sure that there was gas making it to the inlet side. Does anyone have an idea as to why the valve stopped opening once I converted it over?

- I don't know if this will help without seeing your furnace but this is similar to what happened when I light ours in the fall.Where the pilot light is if you have one there is a wire sensor and that gets dirty sometimes and needs cleaned at the tip by the pilot,on ours it connects to the gas valve and signals it to open.Good luck to you hope this helps,it also could be a bad valve.

- Q:i want to know where we must use swing check valve and where we must use lift check valve in petrochemical companies. what are the differences ? are they different from the appearance? how can we distinguish between them visually?

- Horizontal Lift Check Valve

- Q:The tricuspid valve is closed: a. during the rapid filling of the ventriclesb. when the mitral valve is openc. during ejection of blood from the ventriclesHelp plzThank you!

- The tricuspid valve is the connection between the right atrium and the right ventricle, so when blood is rapidly flowing from the RA to the RV, the tricuspid must be open, so it's not A. The tricuspid and the mitral valve open simultaneously so it's not B. As the RV contracts to eject the blood from its chamber to the pulmonary artery, the pressure created within the chamber closes the tricuspid valve to prevent the blood from flowing back to the R Atrium, so the answer is C.

- Q:How many valves are involved in th etypical 4-stroke cycle? Is it the intake and exhaust valves only? If my car engine has 12 valves, how many cylinders does it have?

- nowadays usually it's four valves per cylinder, though still u may find 2 valves per cylinder. u cann't know how many cylinders u have from knowing the number of valves, it depends on the design.

- Q:We just got a new washer and cannot remove the old hoses from the pipes with the shut off valves on them. I don't want to bend or break anything. any suggestions?

- Hold the valve with a pair of pliers and use another pair to loosen the hose connection. This will prevent twisting the valve and its piping. You could spray a little wd-40 on them first.

- Q:Liquid propane leaving the reflux pump of a distillation column flows through a 3.5 in ID pipe at a flowrate of 90 lbm/s. There is a flowrate control valve in this line, and it is set such that the pressure drop across the valve (delta)P=15 lbf/in^2. Upstream of the valve , the pressure P1=18 bar and the temperature T1=310 K. Assume there is negligible heat transfer with the surroundings and that the density of the liquid does not change significantly.a) What is the kinetic energy change across the valve?b) What is the enthalpy change across the valve?c) What is the temperature change across the valve?d) What is the entropy change across the valve?

- If there is NO change in the density of liquid propane as it passes through the valve, and if the size (area) of the pipe upstream and downstream of the valve is the same, then a) there will be no change in the velocity of propane, hence there will be no kinetic energy change. b) this is a process of throttling, with no change in kinetic energy, hence there is no change in the enthalpy. c) temperature change can be determined using the detailed property table of propane, but if it is an almost-incompressible liquid, then this too, will be negligible. d) dh = T ds + v dp. Since there is no change in h, integrate this along a constant h line from inlet to exit (upstream to downstream) and you will get ds = -(v/T) dp. Since p reduces from inlet to exit, the change in entropy will be positive. This is as expected. If we assume density (=1/v) and temperature (T) to remain constant, then the change in entropy will be s_downstream - s_upstream = (p_upstream - p_downstream) v /T.

- Q:Hi all,My 1995 nissan altima (122k on the odometer) stalled for a few minutes this morning. I noticed that one of the sparkplug holes ( where the cable from the distributer connects to the spark plug) is sorrounded by oil. I cleaned it out and it got filled with oil again. luckily for me, and by god's grace it somehow started normally and i drove home. I am sure its the valve gasket. There is not much oil leakage, the oil level is fine.I need to know if its going to damage my engine if I ignored the problem for 3-4days.Thanks.

- Check okorder /

- Q:is it possible to check valve to piston clearance with out taking the heads off? I want to buy a bigger camshaft for my 351 windsor stock pistons with 1970 heads. cam is 230 duration (280) and 512 lift

- The piston isn't the issue here, the issue would be the valve springs. Stock Ford small block springs will bind at .500 lift, this cam will require new springs. If you don't have adjustable rocker arms (most Fords are a postive stop or torque value) you will need an adjustable valve train also. 351s and 289s BOTH use 4 inch pistons, and you CAN'T put a 3.5 inch (351) crank in a 289!

- Q:Which is worse ? And what causes it? I was told I had mitro valve prolapse but I m symptoms had worsen and so I saw a cardiologist again today and they said I have mitro valve regeritation.

- MItral vale prolapse is the problem that is causing the regurgitation. Regurgitation is backward flow of blood. Prolapse is a situation where an anatomical part has slipped out of its normal position. When a heart valve is prolapsed it doesn't close completely, and blood leaks backwards when the heart beats.

- Q:My vehicle has 160,000 miles and has burned 2 quarts of oil at 3000 miles. Someone told me to change the PCV valve because sometimes a bad PCV valve can cause oil consumption. I appreciate your assistance.

- It coming out of the valve cover(s) there maybe more than one. You can tell what it is by the way it bends at 90 degrees and to remove it just pull up on it it'll pop right out. If you shake it and it clicks. That's not your problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double PN 4 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords