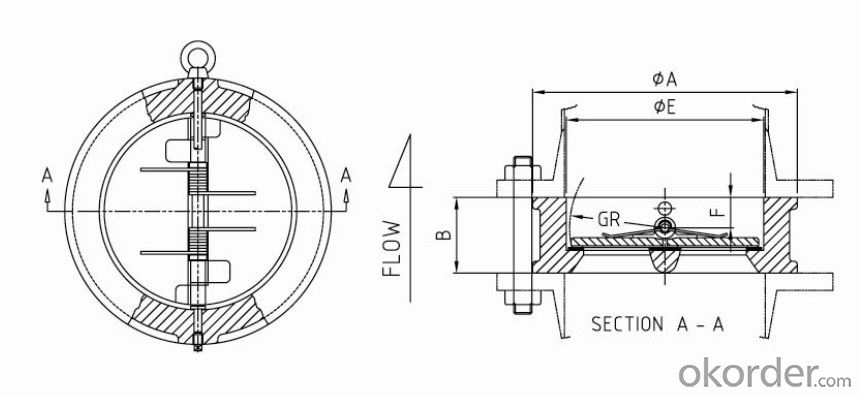

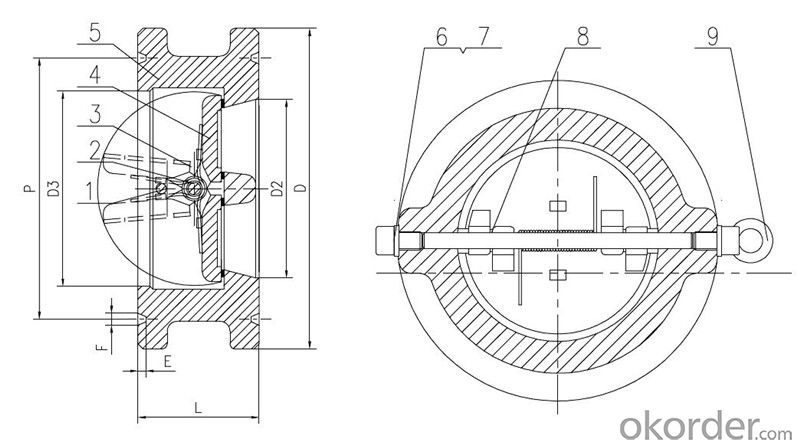

Swing Check Valve Wafer Type Double Disc DN 600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:Ive been tolding one or more of my valves is/are knocking, how can I fix this. Detail would be great, this is for a F0RD 460, from a 90. I was wondering if I can just buy some used heads(not sure if this comes with these things called valves, haha)but I can pick up some 460 heads, for pretty cheap.. on those and do a full swap, since mine is from 90 i dont know if year would matter. So how can I fix knocking valves., thanks

- Valve noise is usually caused by a bad hydraulic lifter, or a worn cam lobe, sometimes wear in the rocker arms also. I don't think changing the heads would help much in your case. I woud get a good mechanic to listen to it, and tell you first ok, because sometimes, just changing the oil and putting in an additive will stop noisy valves good luck

- Q:I'm installing a shut off valve under my sink. can you tell me all the materials that i need to install it by myself because to hire some body else is very expensive where i live. i need to change the old ones because they are leaking very bad when i want to use the sink.thanks a lot

- It sounds to me like they are leaking from the handle when you turn them on to use your sink? If this is the case all you need to do is shut iff the main take the screw out of the handle and remove handle. Then take off the packing nut and replace the packing material. There are only two types of packing either an O ring or rops packing. Talk to the guy at your local hardware store he can tell you what you have. You may not have to replace the actual shut off valve.

- Q:I have a 1997 Toyota Corolla. My check engine light has been on. I tried to get my car smogged and it failed. I then got an oil/air filter change and just yesterday I replaced the EGR valve which was the result given after 2 diagnostic tests. The mechanic gave me my car and the check engine light was off, I've only driven about 5miles and the light is back on. I have to pass smog asap to register my vehicle. I plan on calling the mechanic back and telling him the light is on, but could it just be a sensor?

- it could be a sensor ! the EGR code probably showed up because a sensor was interfering with the valve !

- Q:I'm at school reading a mag and all the internet is blocked except yahoo. So i'm trying to figure out what the diff is between 3 angle versus 5 angle valve jobs.

- The object of the valve angles is to produce a smooth transition to help air flow. So a 5 angle valve job is done to make a series of angles that are closer to a even radius or even parabolic. For street use, you not see that much difference. But when you are at the top levels of competition that little bit might be the difference between an also ran and a winner (read winnings).

- Q:and describe the direction and type of blood (oxygenated ot nonoxygenated) that flows through this valve.

- Mitral valve has two cusps. It is located between the left atrium and the left ventricle , oxygenated blood comes from the lungs by pulmonary veins and drains into the left atrium then the left atrium pumps this oxygenated blood through the mitral valve into the left ventricle. After that the left ventricle contracts pumping the blood through the aortic valve to the aorta..

- Q:Where are the valves. And how do I fix it? Will I have to buy anything? I have a 98 Honda fourtrax 300.

- ticking okorder /

- Q:The automotive machine shop who is working on my Corolla head and block said that one of the valves was severely burnt. What causes burnt valves???

- Several things, the most common being too much heat in the combustion chambers. The heat literally melts slots in the valve face-I had one from 4.9 Ford truck with a clogged radiator that made the valve look like a sand dollar. Anything causing it to run hot , or hotter than designed, needs to be addressed. The other common problem is opening the exhaust up TOO much-Exhaust valves(which, by the way, are the ones that burn 95% of the time), are designed to have exhaust system backpressure help seat them when they close, thereby transferring the maximum amount of heat from the valve face onto the valve seat, which cools them down before the next cycle. Taking off converters, and staight-piping the exhaust will almost always result in burnt valves. An inoperative EGR system, which by design lowers the combustion chamber temperature , can contribute to valves burning.Overheating , however, is the most common cause.

- Q:after my hot water tank shuts off about 1/4 cup of water comes out therelief valve. i changed the relief valve. the tank is 6 months old

- Do you mean the heating (burner or heating coils) shuts off. If that is the case then you may need an expansion tank. If there is a reverse flow valve at your meter (most locations now require this feature to prevent back flow of water to the main line.) the pressure in your system can build up higher than normal when the hot water tank is heating. Most systems have a small expansion tank installed near the hot water heater to deal with this problem.

- Q:I live in Houston (where it hardly EVER freezes during the winter..) This winter it froze and the valve on the sprinkler system flew off and water started shooting straight up. Now that it's getting warmer and I'm going to need the sprinkler.. I have to repair it. Is this an easy fix that I can do myself? Or should I call someone.

- If you are talking about the above ground vacuum breaker go buy one that looks just like it some couplings pipe and glue and a small saw . The rest should be obvious .

- Q:I own a 2001 Chevy cavalier Z24 with a dual cam... Just got it tuned up and noticed oil in my spark plug sockets, which leaves me to assume either the valve cover gaskets or the cam carrier gasket is leaking oil... I would prefer to so this by myself considering I'm sure it's going to be costly.. Anyone have any ideas on how I go about replacing either?

- valve cover shouldn't be that much of a problem as long as you have some basic tools and some mechanical ability. Take it that its a 4 cylinder car, the size of the motor is very helpful when looking for tips. Just don't over torque your bolts when replacing. 89 in lbs is about normal on gm's valve covers

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords