Swing Check Valve Wafer Type Double Disc Body Material CF8M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

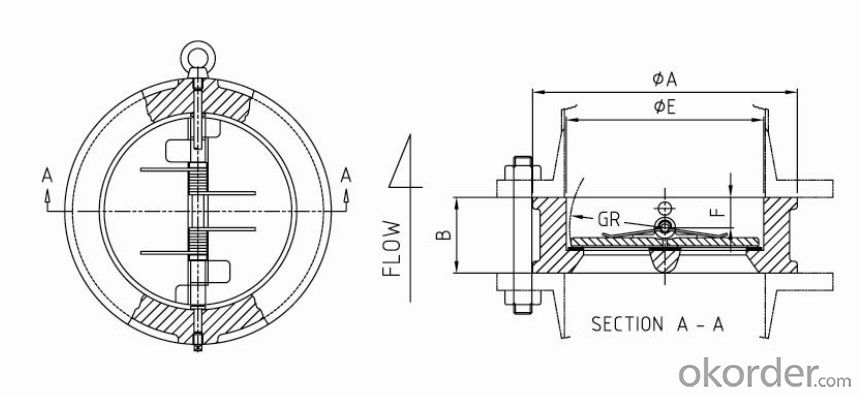

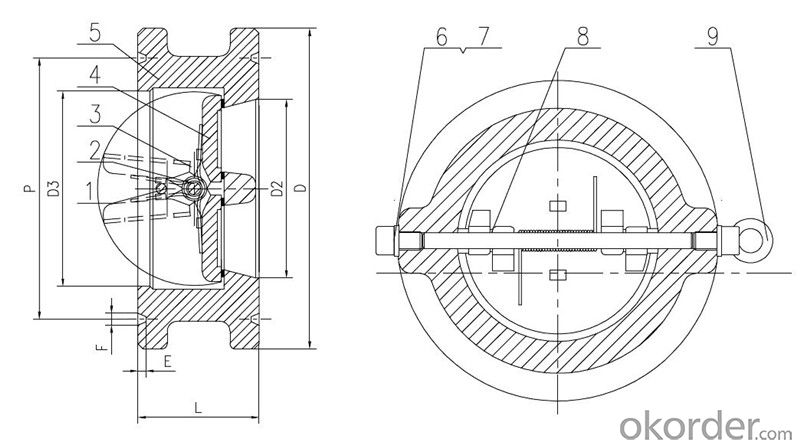

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customiz |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:the #2 valve on my marching bartone wont lock into place instead when i play the valve turns and the air is flow is disrupted i believe that the part that holds the valve in the right positoin is broken if so how much would it cost to repair?

- Virtually any physical exercise melts away unhealthy calories

- Q:I'm drawing a complete diagram of the heart, but I'm unsure of the positions of the different valves. I know there are the pulmoary valve, the aortic valve, tricuspid/right AV, bicuspid/left AV, semilunar valves, mitral...but I know there are several names for some of them, like I think the mitral and the bicuspid are the same...but there are so many sources online I don't know which to believe. If anyone knows for absolute sure the right names and where they are it would be very appreciated if you could help :)

- the bicuspid is the same as the mitral valve it seems like anatomy has 12 names for everything In anatomy, the heart valves maintain the unidirectional flow of blood in the heart by opening and closing depending on the difference in pressure on each side. They are mechanically similar to reed valves. There are four valves in the heart (not counting the valve of the coronary sinus, and the valve of the inferior vena cava): The two atrioventricular (AV) valves between the atria and the ventricles, also called tricuspid and bicuspid. The two semilunar (SL) valves, in the arteries leaving the heart, also called pulmonary and aortic. This I know for sure. Drawing pictures always helped me keep it straight and I just got an A in anatomy. best of luck to you

- Q:I really like the sound that a blow-off valve makes when they are in audi tts. So I was wondering if I got one for my '02 225hp Audi tt if it would damage the engine in any way. I have read that diverter valves are better, but I want the sound of the blow-off valve. Also any recommendations on blow-off/diverter valves would be great.

- Blow off valves are nice, but they aren't terribly good for your car. The main problem is that when the turbo isn't running, that open valve will suck unfiltered air into the engine and can seriously damage it. Blow offs are also pretty inefficient as you lose a good portion of the air in your turbo system. The best thing you can do is just get a good Forge diverter valve. Well made, looks nice, and will add a pretty decent amount of performance.

- Q:Friends,is there anyone know about LinX(Linear Exchage)Valve,how they work.thanks in advance

- A major improvement in the DWEER system has been the development of the LinX (LinearExchanger) valve, which was patented byShumway . This valve replaced eight two-way valves with asingle multi-port spool valve which simplifiedthe system, improved reliability, reducedmaintenance requirements and allowed for fastervalve switching, reducing the size (and thus cost)of the energy recovery vessels. DWEER systemsutilize long vessels which may be installed underthe membrane vessels. Atpresent, the largest available DWEER system has a capacity of 500 m?/h. DWEER (Dual Work Exchanger EnergyRecovery)

- Q:okay, well, I understand partials. But, on a trumpet, what does each valve do? I mean, I had this idea that each one was a half-step up from the previous...but that's not true. Is there some sort of pattern to them? Does each one have a different purpose?...Please answer as basically as possible. I don't play music very often, and I definitely don't speak brass-ish.

- Trumpet Valve

- Q:I need to know how to use a valve spring compressor, the type that looks like a c-clamp. I understand the fork side goes on top of the spring and the circular side goes on the valve to push and hold. There are also two little scoop things in the middle of the fork that i don't know what they are used for. If i can get a step by step instruction, you will get the best answer

- save yourself the hassle and throw that thing away go back to your local auto parts store and buy the l shaped spring compresser should be about twenty dollars make sure vehicle is at tdc remove rocker arm bolt remove rocker arms going valve by valve do not mix them up must go in exactly the same order they came out now lightly tap the top of valve with a rubber mallet will help loosen retainers place compresser on rocker arm stud take r.a. nut and tighten till valve locks fall out or can be removed very small dont lose use compressed air to hold valves in place at tdc sorry that should have been first not hard but not easy to do rebuilt 350 motor from the guts out spent alot of money on spring compressers only to find out the simplest one worked the best the one like u got will give u hell i tried napas version craftsman all of them trust me use the L bar

- Q:Cylinder head valves.Can't really differentiate the difference between burnt and just carbon build up on valves. Are they the same?If I the valves have no cracks or holes, can I clean the carbon off of them and reuse them.If they don't leak when I re-leak test them, are they then good to use?Had very little compression in one cylinder.What cleaner is safe to use on the valves?I know I should replace all, but any money I can save right now, helps a lot.Also I seen a method of re-lapping the valves by using a tool (stick with a suction cup on end that sticks to valve surface) that you spin while valve is seated. It refinishes the seat and recreates the seal/re-laps. Appears to work and seal just fine. Anything really wrong with this method?

- If the valve is burnt there is nothing you can do with it but replace it. If they only need cleaning up you can lap them in with a lapping compound the danger with that is that you need to watch that you do not get close to the edge of the valve, that is when you will end up with a burnt valve. The valve should not be flush with the valve seat that is way to close and the heat of combustion will have a stronger effect on the material.

- Q:what is a silicone purge valve.

- A purge valve is used when a system or object can sometimes be filled with unwanted substances during normal use, as a way to eliminate those substances without complete disassembly. A 'spit valve' (a kind of purge valve) is built into some musical instruments to allow getting rid of saliva which builds up inside during playing. Snorkels used for skindiving often have purge valves (some even made from silicone) to make clearing water easier. A purge valve may be used to drain occasional condensation from inside a gas line. If this is too general, please edit your question to add details.

- Q:Our water heater (bought in 2007 so still fairly new still under warranty luckily) seems to release water from the pressure release valve quite frequently. Everyone seems to say that it shouldn't do it often and ours probably does it a couple times per day. 2 main questions - 1. Is there really a risk of too much pressure building up and the water heater exploding (that's what the sales guy at Lowe's said) and 2. Any idea what the problem might be/what we should check out?

- Two possibilities: When cold water is heated by the water heater it expands. In most houses the tiny bit of extra volume caused by this expansion flows back out the main line toward the street and the water pressure in your home remains constant. Some homes get such high water pressure from the utility that a pressure regulator valve is added where the water main enters the house. But pressure regulators are, by nature, backflow preventers. So now the small increase in volume from heating water results in a large increase in pressure - which is bled off by the Watts valve on your water heater. The only problem is that Watts valves are designed to operate very infrequently and only in an overpressure emergency. Yours is operating multiple times per day and functioning as a pressure control rather than as an emergency release. This can lead to premature fialure and it cn be dangerous. If you have a pressure regulator or a backflow prevention valve on your water main, ten you must have a properly installed expansion tank. The other possibility is that the Watts valve is starting to fail and should be replaced - they normally last the life of the water heater - but you may have gotten a 'bad' one. So, check for a pressure regualtor or backflow preventer and if you have you get a pressure tank, otherwise try just installing a new Watts valve.

- Q:I have a 1994 Toyota 4x4 pickup with the 4 cylinder motor. How do I check to see if the pvc valve works?

- pull the pcv valve out and shake it, if it rattles, its good, also check to see if its working. start your truck and check for suction, by putting your thumb over the valve, if no suction, take the hose off and clean out the hose and fitting, its probably clogged up.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF8M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords