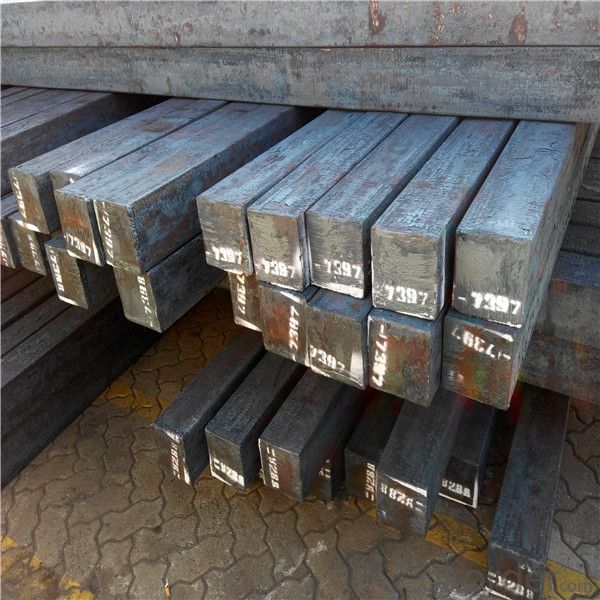

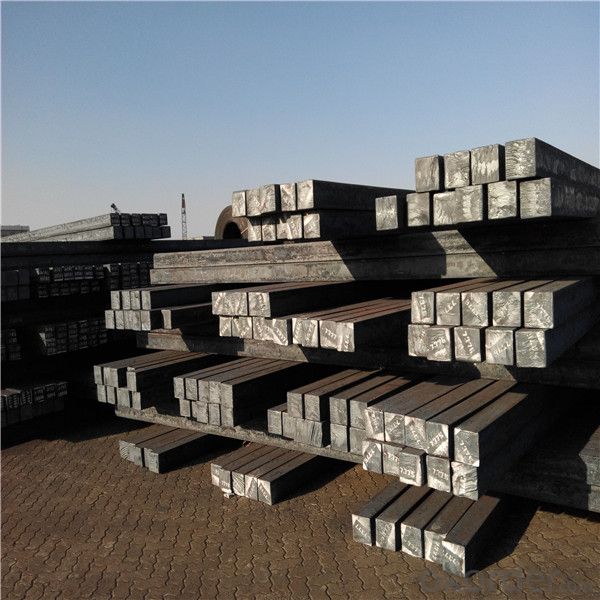

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

Used for the plant, the bridge,shipment building high rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:How do steel billets contribute to the overall energy efficiency of a structure?

- Steel billets contribute to the overall energy efficiency of a structure in several ways. Firstly, steel is a highly durable and long-lasting material, meaning that structures built with steel billets have a longer lifespan. This reduces the need for frequent maintenance and repairs, which in turn lowers energy consumption and costs over time. Secondly, steel is an excellent conductor of heat and electricity. This property allows for efficient distribution of thermal energy throughout the structure, reducing the need for additional heating or cooling systems. Steel structures can effectively regulate internal temperature and minimize energy loss, resulting in improved energy efficiency. Furthermore, steel manufacturing processes have become increasingly energy-efficient over the years. Modern steel production techniques involve recycling scrap steel, using electric arc furnaces, and implementing advanced technologies to minimize energy consumption during the production of steel billets. This focus on energy efficiency in the manufacturing stage translates into reduced environmental impact and energy savings throughout the life cycle of the structure. Additionally, steel structures can be designed to maximize natural lighting and ventilation, reducing the reliance on artificial lighting and mechanical ventilation systems. By incorporating features such as large windows, skylights, and well-designed air circulation systems, steel structures can minimize the need for energy-consuming lighting fixtures and HVAC systems, further enhancing energy efficiency. In summary, steel billets contribute to the overall energy efficiency of a structure through their durability, thermal conductivity, and the energy-efficient manufacturing processes used to produce them. By choosing steel as a building material, structures can benefit from reduced maintenance needs, efficient temperature regulation, and minimized energy consumption, leading to long-term energy savings and a more sustainable built environment.

- Q:How do steel billets contribute to the manufacturing of household appliances?

- The manufacturing of household appliances heavily relies on steel billets, as they serve as the fundamental material for creating various components and structures used in these appliances. To begin with, steel billets are utilized in the production of frames and structures for appliances like refrigerators, washing machines, and dishwashers. The exceptional strength and durability of steel make it an ideal choice for these purposes, ensuring that the appliances can endure constant use and heavy loads. Moreover, steel billets are employed in the manufacturing of both inner and outer panels for household appliances. These panels require a material that possesses strength, resistance to corrosion, and aesthetic appeal. Steel perfectly meets these criteria, providing a sleek and long-lasting surface that can be easily cleaned and maintained. In addition, steel billets are essential for creating various components found within household appliances, including heating elements, motors, and electrical parts. Steel's remarkable thermal conductivity and electrical properties make it a suitable material for these crucial components, guaranteeing efficient operation and reliable performance. Additionally, steel billets contribute significantly to the overall safety of household appliances. Steel is highly resistant to fire, reducing the risk of accidents caused by overheating or electrical malfunctions. Furthermore, its strength and stability play a vital role in preventing structural failures that could lead to accidents or injuries. In summary, the strength, durability, corrosion resistance, and thermal/electrical properties of steel billets make them indispensable in the manufacturing of household appliances. By providing the necessary raw material, steel billets enable the production of robust structures, appealing panels, critical components, and safe appliances that meet the expectations and demands of consumers.

- Q:What are the different methods of steel billet surface etching?

- There are several methods of steel billet surface etching, including chemical etching, electrochemical etching, and laser etching. Chemical etching involves immersing the billet in a solution that reacts with the surface to remove a thin layer of material. Electrochemical etching uses an electric current to dissolve the surface of the billet in a controlled manner. Laser etching uses a high-powered laser to selectively remove material from the surface, creating a permanent etched pattern. These methods offer different levels of precision, depth control, and speed, allowing for various applications in steel manufacturing and surface treatment.

- Q:What are the main factors affecting the formability of stainless steel billets?

- The formability of stainless steel billets is influenced by several key factors. These factors include the steel's composition, the forming temperature, the grain size and structure of the material, and the level of deformation applied during the forming process. To begin with, the composition of the stainless steel billet is a critical factor in determining its formability. The steel's composition, including the presence of alloying elements like chromium, nickel, and molybdenum, impacts its mechanical properties. For instance, higher levels of chromium can enhance corrosion resistance but may reduce formability. Therefore, selecting the appropriate stainless steel grade is essential to ensure optimal formability for a specific application. Furthermore, the temperature at which the stainless steel billet is formed is influential. Elevated temperatures increase the steel's ductility and, consequently, its formability. Heating the billet lowers its yield strength and facilitates easier deformation. However, excessive heating can result in grain growth and diminished mechanical properties. Thus, finding the right balance between temperature and formability is crucial. The grain size and structure of the stainless steel billet also affect its formability. In general, materials with finer grains exhibit better formability compared to those with coarser grains. Finer grains allow for more uniform deformation and reduce the likelihood of cracking or tearing during forming processes. Additionally, the presence of microstructural features like precipitates or twins can also impact the formability of stainless steel billets. Lastly, the amount of deformation applied during the forming process has a significant effect on the formability of the stainless steel billet. Excessive deformation can lead to strain hardening, making the material less ductile and more prone to cracking. Thus, careful control of the amount and distribution of deformation is necessary to achieve optimal formability. In summary, the formability of stainless steel billets is influenced by the composition of the steel, the forming temperature, the grain size and structure of the material, and the level of deformation applied during the forming process. Understanding and managing these factors are essential for achieving the desired formability and ensuring successful manufacturing of stainless steel components.

- Q:How are steel billets inspected for defects?

- Steel billets are inspected for defects through a series of thorough and systematic processes to ensure the quality and integrity of the final product. The inspection methods used may vary depending on the specific requirements and standards of the industry, but generally, the following techniques are commonly employed: 1. Visual Inspection: Skilled inspectors visually examine the surface of the billets for any visible defects such as cracks, surface irregularities, seams, or any other abnormalities. This is the initial step to identify any obvious defects that may affect the quality of the billets. 2. Magnetic Particle Testing (MPT): MPT is a non-destructive testing method that utilizes magnetic fields and iron particles to detect surface and near-surface defects in steel billets. The billets are magnetized, and iron particles are applied to the surface. If there are any defects, the magnetic field will cause the particles to cluster around them, making them visible to the inspector. 3. Ultrasonic Testing (UT): UT uses high-frequency sound waves to inspect the internal structure of steel billets. A probe is used to transmit ultrasonic waves into the billet, and the reflected waves are analyzed to determine the presence of any internal defects like voids, inclusions, or cracks. 4. Eddy Current Testing (ECT): This technique uses electromagnetic induction to identify surface and subsurface defects. A probe is used to create eddy currents within the billet, and any disruptions caused by defects will alter the electrical conductivity, which can be detected and analyzed. 5. Radiographic Testing (RT): RT involves the use of X-rays or gamma rays to inspect the internal structure of steel billets. The billets are exposed to radiation, and the resulting image is examined for any internal defects such as cracks, voids, or inclusions. 6. Ultrasonic Phased Array Testing (PAUT): PAUT utilizes multiple ultrasonic beams to inspect the entire volume of the billet. This technique allows for better defect detection and sizing by controlling the beam angle, frequency, and focus. These inspection methods are typically performed at various stages of the manufacturing process, including before and after the billets are heated, rolled, or further processed. By implementing these rigorous inspection techniques, manufacturers can identify and address any defects early on, ensuring the quality and reliability of the steel billets.

- Q:Billet production process

- Billets are produced by three process methods:First, through the steelmaking system of continuous casting equipment, from the direct pouring of molten steel billet;

- Q:What are the different types of heat treatment processes used for steel billets?

- There are several different types of heat treatment processes used for steel billets. Some commonly used methods include annealing, normalizing, quenching and tempering, and case hardening. Each process has its own purpose and is used to achieve specific properties in the steel billets.

- Q:Are there any alternative materials to steel billets in certain applications?

- There exist several alternative materials to steel billets in certain applications, encompassing the following: 1. Aluminum: Exhibiting a lightweight nature and resistance to corrosion, aluminum serves as a prevalent substitute for steel in situations where reducing weight holds significance, particularly in the aerospace industry. 2. Copper: Possessing ductility and high conductivity, copper frequently finds usage in electrical and plumbing applications, offering an alternative to steel billets when elevated electrical conductivity becomes necessary. 3. Titanium: As a lightweight and robust material, titanium commonly serves in scenarios requiring both strength and resistance to corrosion, notably in the automotive and aerospace industries. 4. Composite materials: Carbon fiber reinforced polymers and similar composite materials increasingly serve as alternatives to steel in critical applications where weight reduction and high strength prove imperative, such as aircraft construction and high-performance sports equipment. 5. Plastic: For applications not demanding substantial strength or durability, plastic can substitute steel billets. Plastic showcases a lightweight quality, cost-effectiveness, and ease of molding into diverse shapes. When selecting an alternative material to steel billets, it remains crucial to consider the specific requirements of each application, as each material possesses its distinct properties and limitations.

- Q:What is the drop per minute of the billet temperature at 850?

- Cold rolling is not considered. The initial rolling temperature (surface) of the billet is generally 1000-1150 degrees.

- Q:Can steel billets be used in the production of railway infrastructure?

- Steel billets have the capability to be utilized in the production of railway infrastructure. These semi-finished products are commonly employed as raw materials in the manufacturing of different steel products. In the context of railway infrastructure, steel billets can undergo further processing and shaping to create various components like rails, sleepers, and fasteners. Rails, which serve as the tracks on which trains operate, are typically crafted from steel billets. These billets are heated and passed through a rolling mill to achieve the desired rail profile. The resultant rail then goes through additional processing to meet specific requirements such as strength, durability, and resistance to wear and fatigue. Similarly, steel billets can also be employed in the production of sleepers, which are the supportive structures that hold the rails in place. Sleepers are commonly made from prestressed concrete or steel, and steel billets can be used as the raw material for manufacturing steel sleepers. Furthermore, steel billets are also applicable in the production of various fasteners that are integral to railway infrastructure. These fasteners include rail clips, bolts, nuts, and washers, which are used to securely fasten rails to sleepers and other components. In summary, steel billets play a critical role in the production of railway infrastructure. They provide the essential raw materials for manufacturing rails, sleepers, and fasteners, thereby contributing to the construction and maintenance of railway tracks, bridges, and other indispensable infrastructure elements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billet Low Price in high quality hot sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords