Static Var Compensator(SVC)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Static Var Compensator(SVC)

SVC-solved problems

Electric arc furnace

When the electric arc furnace connects to grid as one nonlinear and ruleless load, it will trigger a series of harmful effects, which mainly includes:

1. Severe 3-phase unbalance of grid, and negative sequence current.

2. Higher harmonics, the coexistence of 2f, 4f, the even harmonics and 3f, 5f, 7f, the odd harmonics, which will perplex the voltage distortion.

3. Severe voltage flicker.

4. Low PF.

The only way to completely solve above mentioned problems is that user must provide the SVC with rapid response speed for electric arc furnace. Since the response time of SVC is less than 10ms, it can completely meet the strict technical requirements, swiftly provide reactive current for EAF, stabilize system voltage, increase output of metallurgical active power and enhance production efficiency, as well as minimize the flicker effect. The phase splitting compensation capability of SVC can eliminate 3-phase unbalance caused by EAF. Harmonics filtering device can remove harmful higher harmonics, improve power quality and increase PF by transferring capacitive reactive power to system.

◆ Rolling mill

The reactive power impact caused by rolling mill and other industrial symmetrical loads during normal operation will cause the following effects for grid:

1 gird voltage decreasing and fluctuation, or even the electrical devices can not work normally, production efficiency will be reduced.

2 PF decreasing

3 Harmful higher harmonics existing in load transmission device, like 5f, 7f, 11f and 13f odd harmonics, will distort grid severely.

SVC can solve the above mentioned problems easily and perfectly, through stabilizing the busbar voltage without harmonics disturbance, making PF approaching to 1.

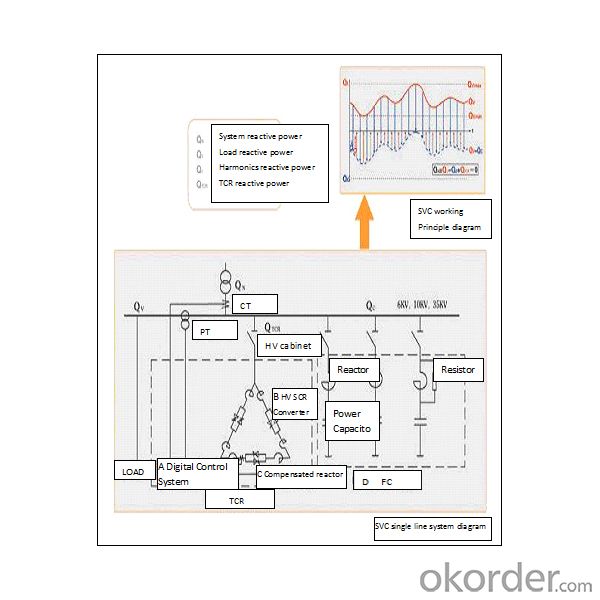

SVC principle

TCR type SVC is widely used in the world, it can eliminate reactive power impact, filter higher harmonics and balance 3-phase grid.As shown in this diagram, SVC is connected with system, capacitor provides fixed capacitive reactive power Qc, current passing the compensated reactor determines the output value of inductive reactive power QTCR of compensated reactor, then inductive reactive power offsets capacitive reactive power. As long as system reactive power Qn=Qv (demand by system)-Qc+QTCR=constant (or 0), then grid power factor will equal to one constant, voltage will not be unstable any more. For this purpose, the contact angle of thyristor must be controlled precisely in order to get the required current value passing the compensated reactor, while converter and control system of thyrister can help to achieve this through calculating the contact angle opening after combining the collected current and voltage values of busbar reactive power, and comparing it with setting constant reactive power (maybe 0), and then setting the required current for thyrister by triggering device.

For asysmetrical loads, steinmetz theory will be used to adjust phases separately, eliminate negative sequence current and balance 3-phase grid.

SVC Composition

A. Whole digital control system

Cabinet structure, timely calculate reactive power of grid, control opening of thyrister contact angle, so as to control compensated reactive power.

B. HV thyrister converter

Cabinet structure

Receive signal from control system, change opening of thyrister contact angle, so as to produce corresponding reactive compensating current.

C.Compensated reactor

Hollow dry type, upper and lower double windings, natural cooling

When current from thyrister passes compensated reactor, it will produce the inductive reactive power required by system, which will balance system reactive power, stabilize busbar voltage and pf.

D.Filter of higher harmonics

Composition: reactor, electric capacitor and resistor (used for high pass channel) compose one harmonics filtering channel, however, based on system requirements, they can compose several channels used for corresponding higher harmonics filtering.

Structure: reactor is hollow dry type, upper and lower double windings, natural cooling; electric capacitor is of combined frame, natural cooling.

Function: eliminate the higher harmonics of system, provide capacitive reactive power for system and increase power factor.

Connection: each harmonics filtering channel is connected with system busbar directly or through HV switchgear.

SVC-technical parameters

Items | Specifications | ||||

Grid voltage (kV) | 6 | 10 | 27.5 | 35 | 66 |

TCR rated power |

| ||||

Thyrister valve structure | Opened combined frame type | ||||

Thyrister cooling mode | Heat pipe self-cooling, water cooling | ||||

Thyrister type | Electric triggering thyrister (ETT) or light controlled thyrister (LTT) | ||||

Triggering mode | Optical or light | ||||

Control system | DSP digital control system | ||||

Control mode | Reactive power | ||||

Adjusting range of reactive power | -100%—+100% | ||||

Adjusting mode | Phase-splitting adjustment | ||||

Response time of adjusting system | ‹10ms | ||||

Noise level | Self cooling, no noise | ||||

Power supply voltage of auxiliary grid | 380V±15% | ||||

Lifespan | ›20 years | ||||

HV and LV passive filter

HV harmonics filter

HV harmonics filter is dedicated for passive filtering device which is used for filtering of 3f, 5f, 7f, 11f, 13f, or even higher harmonics. It is adaptable for equipment with large harmonics, such like, medium frequency furnace, arc furnace, frequency conversion, hot milling, rectifying device, etc. Harmonics filter uses resonance absorption circuit composed by cascade connected reactor and capacitor, to absorb harmonics efficiently, so as to avoid harmonics current being feeding back to transformer and grid, meanwhile it can decrease grid harmonics efficiently, avails normal operation of transformer, decrease power loss and increase reliability of equipment and other electrical components. Besides, this equipment is also equipped with certain reactive power compensation, which can increase operation efficiency of user’s load. Each equipment is designed based on user’s requirements and is provided with best harmonics filtering performance and reactive power compensation ability, so that it can increase efficiency of user’ load and get efficient investment interest.

Composition and principle

It is composed of several groups of FC single turning filter and high pass filtering branches, while each group is composed of harmonics filtering capacitor and reactor. It absorbs featured harmonics effectively, thereby decreases system harmonics.

Main technical index

Executive standard GB50227-95 GB3983-89 JB7111-93 GB/T 14549-93

ambient temp. -10 ℃~ + 55 ℃

relative humidity <90%RH( 25 ℃ )

rated voltage 6 ~ 35KV

harmonics filtering times F5,F7,F11,F13(depends on actual conditions )

harmonics absorption rate >85%

PF at reactive power PCC testing point is larger than 0.92

Indoor or outdoor arrangement, structure, opening cabinet

Indoor opening harmonics filtering device

Cabinet type harmonics filtering devices

Outdoor 35KV HV harmonics filtering devices

LV harmonics filterThe LV harmonics filtering system includes harmonics filter and reactive power compensator, it can eliminates harmonics directly through being installed at LV AC side of medium frequency furnace transformer, so that this system is adaptable for condition that there are few medium frequency furnaces (1-2 sets) or the medium frequency furnace is scattered in different power supply systems, however, this system costs high and requires high centralized treatment, for example, those medium frequency furnaces with 12 pulses and 24 pulses, the filtering system is needed in each side of transformer’s dual secondary sides, that means, one medium frequency furnace of 12 pulses needs 2 sets, and one medium frequency furnace of 24 pulses needs 4 sets.

Harmonics filter can eliminate characteristic harmonics of different voltage levels, for this purpose, it is composed by filter capacitor, filter reactor, non-inductive resistor, which can remove corresponding characteristic harmonics and reduce harmonic pollution. Filter has cabinet and opening structures. Our company has very mature technology of harmonics treatment at LV side, dozens of our products have already run normally.

LV cabinet harmonics filter

LV opened harmonics filter

- Q:What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

- Q:What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q:What's the role of anchor bricks in industrial furnaces?

- Anchorage brick is a new type of anchor brick relates to an industrial furnace, in particular to anchor brick of an industrial furnace roof, including column hanging end and the anchor structure, opened in the anchor on the surface of the spacing of the grooves in the anchor on at least one surface is arranged along the length direction ribs is provided with ribs, the ribs of the reinforcement and anchorage tension, tensile and flexural strength was obviously improved, the stress generated in the groove at the bar at the barrier can not continue to transfer, so the anchor brick of this kind of structure is not easy to break.

- Q:Should the industrial furnace shell cool down?

- If the furnace shell temperature is too high, it shows that the lining is not good or damaged, so it should be repaired in time. If you do not repair, take the cooling way, undesirable. Because this will cause a lot of heat loss, resulting in waste of energy, increase production costs, and affect the service life of the furnace.

- Q:Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q:What is an industrial furnace pit?

- Later, a chamber kiln with a semi closed or fully enclosed kiln made of refractory bricks can be used as fuel for coal, gas or oil, and electricity can be used as heat source. The workpiece will be heated in the kiln hearth.

- Q:How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q:What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Static Var Compensator(SVC)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords