Submerged Arc Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Submerged Arc Furnace

Submerged Arc Furnace Profile

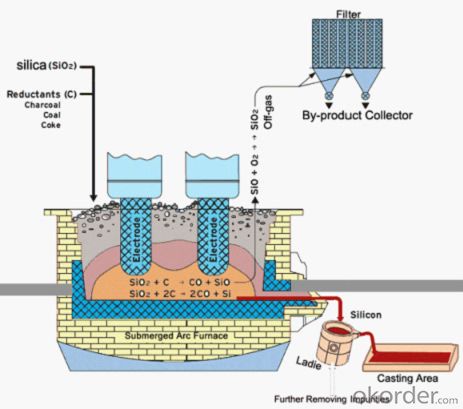

Submerged arc furnace—it’s also known as electric arc furnace or resistance electric furnace. It is mainly used to reducing smelting ore, carbonaceous reducing agent and solvent etc. Mainly adapts to production of ferrosilicon, ferromanganese, ferrochrome, ferrotungsten, silicon manganese alloy and other ferrous alloys, it is an important smelting furnace in metallurgical industry for production of industrial raw materials and calcium carbide and so on chemical raw materials. The working character is to use carbon or magnesia refractory materials as furnace lining, use self roasting electrode. Electrode inserts into the materials inside the furnace for submerged arc operation, using arc energy and current through the materials, and due to the resistance of the materials and produce energy to melt metal. It’s a kind of industrial furnace which is worked continuously, charged material in succession, and tapped out metal or slag in intermittent.

Submerged Arc Furnace---Major categories and application

Category | Main raw-material | Final products | Reaction | Power | ||

Ferroalloy | Ferrosilicon | (45%) | Ferrosilicon, | Ferrosilicon | 1550-1770 | 2100-5500 |

(75%) | 8000-11000 | |||||

Ferromanganese furnace | Manganese | Ferromanganese | 1500-1400 | 2400-4000 | ||

Ferrochrome furnace | Chrome ore, | Ferrochrome | 1600-1750 | 3200-6000 | ||

Ferrotungsten furnace | Tungsten | Ferrotungsten | 2400-2900 | 3000-5000 | ||

Silicon chromium furnace | Ferrochrome, | Silicon chrome | 1600-1750 | 3500-6500 | ||

Silicon manganese furnace | Manganese | Silicon | 1350-1400 | 3500-4000 | ||

Steelmaking electric furnace | Iron ore, coke | Pig iron | 1500-1600 | 1800-2500 | ||

Calcium carbide furnace | Limestone, coke | Calcium carbide | 1900-2000 | 2900-3200 | ||

Boron carbide furnace | Boron oxide, | Boron carbide | 1800-2500 |

| ||

Notes: The above is roughly value. According to the difference of the raw material composition, finished product components, electric furnace capacity and etc. the power consumption value will be much different.

Submerged Arc Furnace---Structure characteristics

Submerged arc furnace is a kind of industrial furnace which consumes much power. Full set equipment mainly consists of furnace shell, fume hoods, lining, short net, cooling system, exhaust system, de-dusting system, electrode shell, electrode lifting system, loading and unloading system, electrode holder, arc burner, hydraulic systems, submerged arc furnace transformer and various of electrical equipments.

Submerged arc furnace equipment is divided into three layer arrangement

The 1st layer is furnace body (including furnace bottom support, furnace shell, furnace lining), tapping system (including the ladle and ladle car.), arc burner etc.

The 2nd layer

1、Fume hood: At present, mostly of submerged arc furnace adopts closed or semi-closed low hood structure, with the characteristics of environmental protection, facilitate maintenance and improve the operation environment. The closed structure can also collect the exhaust gas (main ingredient is carbon monoxide) which is generated in the production and used in synthetically. Also can reduce the heat loss of the circuit, decrease the temperature of the electrode, and improve the operating environment.

2、Electrode holder: Most of submerged arc furnace with three-phase power supply. Electrode in triangle or inverted triangle, symmetrical position placed in the middle of furnace chamber. Large submerged arc furnace generally adopts anthracite, coke and coal tar pitch mixed as electrode material, in the process of smelting , it roasting by itself as electrode.

3、Short net

4、Copper tile

5、Electrode shell

6、Unloading system

7、Stoking machine

8、Fume exhaust system

9、Water-cooling system

10、Submerged arc furnace transformer

11、Operating system

The 3rd layer

1、Hydraulic system

2、Electrode press and release device

3、Electrode lifting system

4、Steel platform

5、Hopper and cycle material distribution car

Other additional: skew Bridge feeding system, electronic batching system, etc.

- Q:What is the difference in structure between industrial furnace and boiler?

- From the way: industrial furnace (electricity, natural gas, gas, induction heating is considered electricity), boilers (coal, all kinds of hot exhaust gas, a variety of gas, seemingly less electricity).

- Q:What are the advantages of a vacuum furnace?

- The accuracy of furnace temperature measurement and monitoring is obviously improved. The indicating temperature of the thermocouple and the temperature of the furnace reach 1.5 C. But there is a large temperature difference in a large number of workpieces in different parts of the furnace. If the forced circulation of the rarefied gas is adopted, the temperature range of the temperature range of + 5 DEG C can still be controlled.

- Q:Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q:Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q:What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q:Brief introduction to repair of industrial furnace

- Compared with other equipment, industrial furnace repair has many characteristics: more repair times, more maintenance costs, more non-standard equipment and unsafe factors.

- Q:What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q:What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q:How to use industrial furnace equipment?

- The protection device of the exposed transmission department shall be installed with the correct installation position. The structure is reasonable. The wire rope pulley of the furnace car shall be intact and undamaged. All the pulleys and sprockets on the furnace are in good condition, without defects and flexible in rolling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Submerged Arc Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords