Stainless Steel Plate 420 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Stainless Steel Plate 420 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

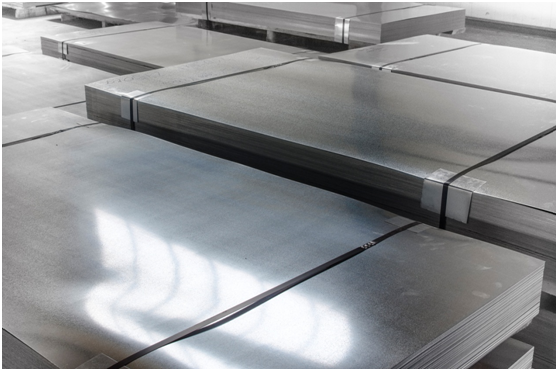

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

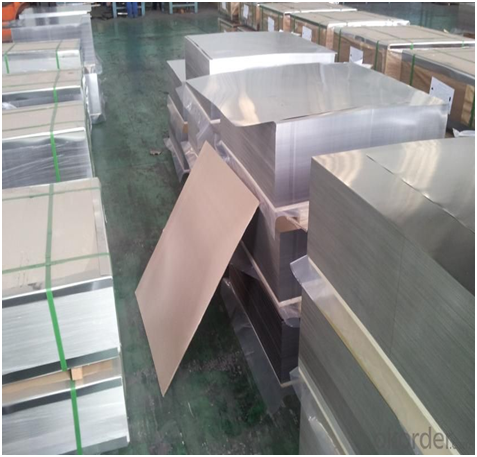

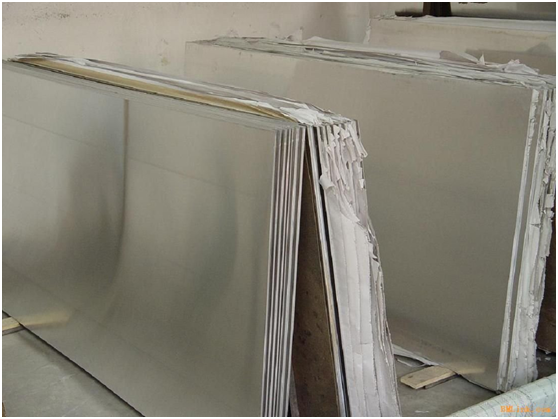

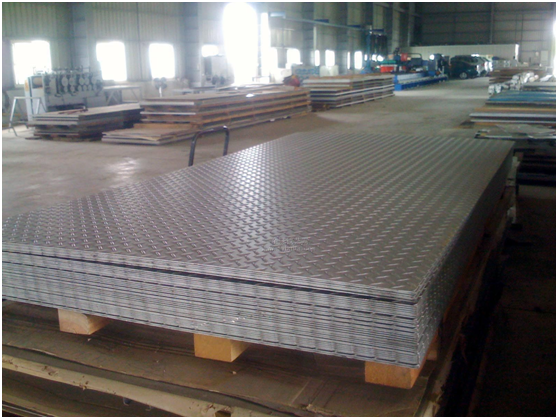

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that is known for its durability, sleek appearance, and resistance to corrosion. It can be easily shaped, engraved, or finished in various ways to create visually appealing designs for elevator doors or panels. Additionally, stainless steel's hygienic properties make it a popular choice for elevator applications.

- Q:Can stainless steel sheets be used for elevator doors or panels?

- Indeed, elevator doors or panels can make use of stainless steel sheets. The utilization of stainless steel in elevator construction is widespread owing to its endurance, robustness, and pleasing appearance. Its resistance to corrosion is vital for elevator doors and panels exposed to diverse environmental circumstances. The adaptability and ease with which stainless steel sheets can be shaped and crafted make them readily customizable to meet the distinct design prerequisites of elevator doors and panels. Furthermore, stainless steel's effortless cleanliness and maintenance contribute to its popularity as a preferred option for heavily trafficked regions such as elevators.

- Q:Are stainless steel sheets suitable for dairy processing equipment?

- Yes, stainless steel sheets are highly suitable for dairy processing equipment. Stainless steel is known for its corrosion resistance, durability, and hygiene properties, making it an ideal material for equipment used in the dairy industry. It is easy to clean, resistant to bacterial growth, and does not react with dairy products, ensuring the safety and quality of the processed food.

- Q:What are the different types of stainless steel sheet finishes for decorative purposes?

- There are several different types of stainless steel sheet finishes that are commonly used for decorative purposes. These finishes are achieved by various surface treatments and processes, each resulting in a unique appearance and texture. Some of the most popular finishes include: 1. No. 4 finish: Also known as brushed or satin finish, it is achieved by applying a series of abrasive belts to the surface, resulting in a smooth, satin-like appearance. This finish is commonly used in architectural and decorative applications. 2. No. 8 mirror finish: This finish is achieved by polishing the surface to a highly reflective mirror-like appearance. It is often used in applications where aesthetic appeal is important, such as wall cladding, signage, and decorative elements. 3. Hairline finish: This finish features a fine, directional grain pattern created by polishing the surface with fine abrasive belts. It provides a subtle and elegant look, commonly used in interior design applications like elevators, appliances, and furniture. 4. Embossed finish: In this finish, the stainless steel sheet is pressed with a pattern or texture, creating a three-dimensional surface. This finish is often used in architectural applications, such as wall panels, ceiling tiles, and decorative trim. 5. Bead blasted finish: This finish is achieved by blasting the surface with fine glass beads under high pressure, resulting in a uniform, matte appearance. It provides a unique texture and is commonly used in applications where a non-reflective surface is desired, such as countertops, kitchen appliances, and signage. 6. Colored finishes: Stainless steel sheets can also be coated with various colors through processes like PVD (Physical Vapor Deposition) or powder coating. These finishes provide a wide range of color options, allowing for more design flexibility in decorative applications. Overall, the choice of stainless steel sheet finish for decorative purposes depends on the desired aesthetic, functionality, and application requirements. Each finish offers its own unique look and feel, allowing for versatile design possibilities in various industries.

- Q:Are stainless steel sheets suitable for brewery equipment?

- Yes, stainless steel sheets are highly suitable for brewery equipment. Stainless steel is a preferred material in the brewing industry due to its many beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for equipment that comes into contact with liquids and chemicals used in the brewing process. This corrosion resistance helps maintain the quality and purity of the beer being brewed. Additionally, stainless steel is easy to clean and sanitize, which is crucial in maintaining hygiene standards in a brewery. It is non-porous, meaning it does not absorb or retain odors, flavors, or bacteria, ensuring the beer is not contaminated during production. Stainless steel also has a smooth surface, preventing the buildup of bacteria or other contaminants that could affect the quality of the beer. Furthermore, stainless steel is durable and long-lasting, able to withstand the demanding conditions of a brewery environment, including high temperatures, moisture, and constant use. This durability ensures that brewery equipment made from stainless steel sheets will have a longer lifespan, reducing the need for frequent replacement or repairs. Overall, stainless steel sheets are an excellent choice for brewery equipment due to their corrosion resistance, ease of cleaning, sanitation properties, and durability. Using stainless steel in brewery equipment helps maintain the quality and purity of the beer, ensuring a better end product for consumers.

- Q:How do you prevent galvanic corrosion when using stainless steel sheets?

- One effective method to prevent galvanic corrosion when using stainless steel sheets is to ensure they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials or coatings, such as rubber gaskets or paint, between the stainless steel sheets and other metals. Additionally, regular maintenance and cleaning of the stainless steel surfaces can help prevent the accumulation of corrosive substances that could lead to galvanic corrosion.

- Q:What are the different types of perforations available for stainless steel sheets?

- There are several types of perforations available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each type has its own unique characteristics and is suitable for different applications and aesthetic preferences.

- Q:Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular material choice for medical equipment due to its corrosion resistance, durability, and easy maintenance. It is commonly used in surgical instruments, medical devices, hospital furniture, and other medical applications.

- Q:Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and it can be melted down and reused to produce new stainless steel products. Recycling stainless steel not only conserves natural resources but also helps to reduce waste and minimize environmental impact.

- Q:What factors affect the cost of stainless steel sheets?

- There are several factors that can affect the cost of stainless steel sheets. These include the type and grade of stainless steel, the thickness and size of the sheets, the quantity being purchased, market demand and availability, production and labor costs, and any additional processing or finishing requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Plate 420 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords