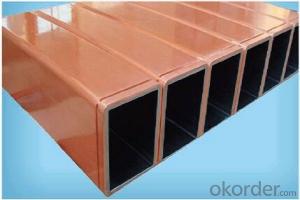

Refrigeration Copper Pipe for New Refrigeration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refrigerant Copper Pipe Type R410A

Model: TP2、TU1、TU2、T2

Application:

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Type Specifications: TP2, TU1, TU2, T2

Primarily applied in household and commercial central air conditioning system; pressure resistant product made by large water seal extruder through degrease process, without residual oil and with low dust load, suitable for refrigeration systems using new refrigerant

Specifications:

Item | air conditioner copper pipe |

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q:I am doing a project for year 9 science, and am a little confused to why copper is such a good conductor. I have tried researching, but dont understand the information I have found.Thankyouxoxox

- Copper is a good conductor because electrons can flow through it easly. Simple as that. The reason why it is a worse conductor cold, is because electrons slow down in cold temperatures. If you heat an object up, such as the material tungston (inside your tv). It moves electrons so fast it shoots them off of the material and at your tv screen which creates an image. Hents why your old color tube tv needed to take a few seconds to warm up before the picture was crisp.

- Q:I HAVE OLD COPPER PIPE TURNING GREEN AND DIRTY INSIDE. CAN I STILL USE FOR MY HOME PLUMBING?

- Clean the inside with vinegar and make sure to clean the ends and the inside of the fittings very good with a brush and emery cloth.

- Q:I am running all new lines and can‘t seem to get a good answer as to why to run copper, but experienced plumbers all say to do it. Is it just the old school mentality or is there some good reasoning? I know cost is a huge difference, but I am willing to go with which ever offers the best benefit to me. I believe plastic is in its 3rd generation and is becoming more commonplace in new construction. Any advice is welcome.

- I have done both as well as galvanized steel and I only do CPVC Schedule 40 for interior water both hot and cold now. It does not sweat in humid weather, insulates hot water feeds and is easy to work with and cheap. It also does not corrode like the old steel did. I have seen the old steel pipes go from 3/4 inch to less than 1/16th when they rusted and had to be replaced. One issue that the older guys have with it is that it does not have the structural strength of metal. So you have to support it properly and watch for sag if you are running it under a floor perpendicular to the floor joist or dropping to a laundry faucet. Also if you do have to open a pipe up there are no unions but that is the same with copper. You don't have to sweat the joints like copper either. As long as you properly support it CPVC is great to work with, lasts a long time and is cheap. Good Luck

- Q:What is the ratio of the capillary and copper tube in the fridge and freezer?

- Horizontal freezer with a diameter of 8mm copper tube coil in general, from the mouth of 5-6cm refrigerator dish in the first circle, and then by ring down plate, each ring spacing of 7cm, about 10cm from the bottom end. The coil is connected to the top of the capillary, the bottom corner opening is connected with the compressor inlet. The coil should be smooth, turn to be accurate, appropriate length of the two parts the card will be fixed on the aluminum coil clamp fixed on the inner wall of refrigerator, without width.The length of the coil: measurement of horizontal freezer freezer wall in a circle circumference; the depth of upper vacated 5CM, at the bottom of the rest of the vacated 10CM, according to the depth of every 7CM disc in a circle, the circle number required coil plus 1 ring (the first circle); the total length of the coil is finally on the perimeter. As measured. The freezer is 1.6 meters, depth of 50 cm.Formula: total length m= (/m-0.15m / 0.07m+ refrigerator freezer depth) /m X - /m perimeter perimeterFor example: the total length of m= (0.5m-0.15m), 0.07m+1.6m X1.6m=10.56mCapillary, no matter how long it is outside the original box, keep the original length, and then the 1.2-1.5m (the length that was buried in the box) is the same as the capillary tube of the specificationThrough the capillary clings to the bottom from the upper angle into the first ring (tube hole should be close to the corner, wearing at the bottom of the capillary and the return pipe are from hole piercing). Such as refrigerated dual-purpose freezer, frozen capillary advanced tube.Compared with the vertical coil pipe has three sideways point: 1, do not waste the corner (not accounted for) refrigerator space; 2, no accumulation of condensed water, so as to avoid the wall decay; 3, running or stopping after the initial boot can effectively avoid liquid hammer compressor.Fast method of self-made refrigerator evaporator and capillary tube!

- Q:What family is the element copper in?

- Copper is a metal, and it's in the 11th group (family) of the periodic table.

- Q:can i use copper pipe for natural gas?

- Hello Balsaxx, There is so much hype regarding natural gas and copper pipes. Just to give you some peace of mind, Many people will say not to connect copper pipes to natural gas, is what they fail to tell you, is that when all houses were built, the original pipe was made from copper, over the years things in the world of construction have changed, they have found new materials to last longer, have found different fluxes applied to the joints on copper pipes to last longer etc etc. I am 100% British, we have houses that are still standing well over 200 years of age, with the addition of gas central heating and modern heating systems. We never use anything but copper for our plumbing, unless the original house was plumbed using lead pipes. I moved to the USA approximately 5 years ago, and am a self employed contractor, we do anything from installing a light fixture to building a dream custom home. Do not get sucked into the false claims that copper will erode and it is a bad thing, Copper is by far the best choice for any plumbing application, and I am positive that when your house was built, the plumbers knew about all the different types of flux. Flux is used to around the joints, to make the soldier run around the joint and create a water tight or gas seal. I have a house that is 140 years old here, all the pipes are copper and the water is supplied from a well, I have a gas furnace and all the pipes are fine, the well water does build up sediment in the pipes, and one of my bathrooms has a shower which is a bit slow, the water pipes/copper pipes connecting the shower is original I.E. 140 years of age. There are too many people hearing horror stories about copper and gas, copper and water etc. You have nothing to worry about, and if you out live your house than maybe consider a change in about 200 years lol. I hope this gives you peace of mind and do not worry. Paul M

- Q:Zinc metal reacts with copper(II) ion in solution to produce zinc ion and copper metal, as follows.Zn(s) + Cu2+(aq) ? Zn2+(aq) + Cu(s)You add 7.675 grams of Zn metal to 27.0 mL of 0.270 M CuSO4·5H2O and allow the reaction to proceed until the blue color of the solution is gone. You note that copper metal is plating out on the zinc pellets. How many moles of Zn have you added to the flask? (Unit is mol).How many moles of Cu2+ ion are in the solution? (Unit is mol).How many moles of Zn will have reacted with the Cu2+ when the reaction is complete? (Unit is mol).How many moles of Zn will remain unreacted? (Unit is mol).What mass of Zn will remain unreacted? (Unit is g).How many moles of Cu metal will be produced? (Unit is mol).What mass of Cu metal will be produced? (Unit is g).When the metal pellets are removed, dried, and weighed, what should be their total mass?

- Molar mass of zinc is 65.40 g/mol, of copper 63.546 (you can find that in a periodic table of elements). Amount of zinc equals n=m/M; 7.675 g/65.40 g/mol = 0.117 mol. Molar concentration (c=n/V) of CuSO4?5H2O is 0.270 mol/L, volume equals 27.0 mL = 0.027 L. Amount of CuSO4?5H2O equals 0.27 mol/L X 0.027 L = 0.000729 mol. Each mol of CuSO4?5H2O gives one mol of Cu2+ ions (CuSO4→Cu2+ + SO42-), so amount of Cu2+ ions in a solution is 0.000729 mol. One mol of Zn reacts with one mol of Cu2+ (Zn + Cu2+→Zn2+ + Cu), therefore 0.000729 mol of Zn reacted. 0.117mol (starting amount)-0.000729 mol (reacted amount) = 0.116 mol of Zn remained in a solution. That means 7.586 g of zinc remained (0.116 mol X 65.38 g/mol). One mol of Zn reacts with one mol of Cu2+, therefore 0.000729 mol of Cu is produced, which is 0.046 g. Total mass of pellets (copper coated zinc) is (starting mass of zinc – mass of reacted zinc) + mass of produced copper: 7.586g Zn + 0.046 g Cu = 7.63 g.

- Q:How much does copper cost a lb?

- depends on the grade ....#1 is bringing between 2-4 dollars here

- Q:for dirty copper and clean I have ALOT trying to find out if is worth cleaning.

- I think the website below is for new copper, not recycled. Check with your local recycler in the yellow pages.

- Q:how much does a 3x10 copper pipe weigh?

- This Site Might Help You. RE: How much does a 3x10' copper pipe weigh?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Refrigeration Copper Pipe for New Refrigeration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords