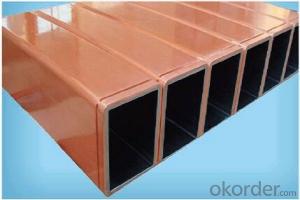

COPPER TUBES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Packing: Wooden pallet packing strong seaworthy, Coils will have to be collected into a pile to build round 3+3 or 7 coils carried on one fumigated wooden pallet. Cardboard flange to be inserted between each coil and to be placed onto the top of the highest one.Shrinking film wrapping the parcel, each parcel composed of 3+3 or 7 coils, will have to be characterized by a label including the dimension, gross weight, tare and net weight, packing number, production date. |

| Delivery Detail: | within 15 days after we received deposite or L/C |

Specifications

1) high efficiency, energy saving healthy

2) the inside surface area increases 70~100% than plain copper tube

We have passed ISO9001, ISO14001, UPC,SGS and TUV etc.,these promise that the products we produced are always of the best quality

1) Alloy no.: C12200, Temper: soft drawn

2) Coil Wt.: 100kg ~ 500 kg

| Specifications | Unit weight | O.D | I.D | Bottom Wall Thickness TW | Fin Groove Depth HF | TotalWallThickness | Apex Angle | Helix Angle | Number of Tooth |

| Φ5.00×0.20+0.15-18° | 33 | 5.00 | 4.30 | 0.2 | 0.15 | 0.35 | 40 | 18 | 40 |

| Φ7.00×0.25+0.10-15° | 52 | 7.00 | 6.30 | 0.25 | 0.10 | 0.35 | 40 | 15 | 65 |

| Φ7.00×0.25+0.18-18° | 57 | 7.00 | 6.14 | 0.25 | 0.18 | 0.43 | 40 | 18 | 50 |

| Φ7.00×0.25+0.22-16° | 58 | 7.00 | 6.06 | 0.25 | 0.22 | 0.47 | 22 | 16 | 54 |

| Φ7.00×0.27+0.15-18° | 60 | 7.00 | 6.16 | 0.27 | 0.15 | 0.42 | 53 | 18 | 60 |

| Φ7.94×0.25+0.18-18° | 65 | 7.94 | 7.08 | 0.25 | 0.18 | 0.43 | 40 | 18 | 50 |

| Φ7.94×0.25+0.20-18° | 66 | 7.94 | 7.04 | 0.25 | 0.20 | 0.45 | 40 | 18 | 50 |

| Φ7.94×0.26+0.17-18° | 66 | 7.94 | 7.08 | 0.26 | 0.17 | 0.43 | 40 | 18 | 50 |

| Φ7.94×0.28+0.20-18° | 72 | 7.94 | 6.98 | 0.28 | 0.20 | 0.48 | 40 | 18 | 50 |

| Φ7.94×0.30+0.20-18° | 76 | 7.94 | 6.94 | 0.3 | 0.20 | 0.50 | 40 | 18 | 50 |

| Φ9.52×0.27+0.16-18° | 82 | 9.52 | 8.66 | 0.27 | 0.16 | 0.43 | 30 | 18 | 70 |

| Φ9.52×0.28+0.12-15° | 80 | 9.52 | 8.72 | 0.28 | 0.12 | 0.40 | 53 | 15 | 65 |

| Φ9.52×0.28+0.15-18° | 83 | 9.52 | 8.66 | 0.28 | 0.15 | 0.43 | 53 | 18 | 60 |

| Φ9.52×0.28+0.15-25° | 88 | 9.52 | 8.66 | 0.28 | 0.15 | 0.43 | 90 | 25 | 65 |

| Φ9.52×0.28+0.20-18° | 85 | 9.52 | 8.56 | 0.28 | 0.20 | 0.48 | 25 | 18 | 55 |

| Φ9.52×0.28+0.20-18° | 88 | 9.52 | 8.56 | 0.28 | 0.20 | 0.48 | 40 | 18 | 60 |

| Φ9.52×0.30+0.20-18° | 90 | 9.52 | 8.52 | 0.3 | 0.20 | 0.50 | 30 | 18 | 60 |

| Φ9.52×0.30+0.20-18° | 94 | 9.52 | 8.52 | 0.3 | 0.20 | 0.50 | 53 | 18 | 60 |

| Φ9.52×0.34+0.15-25° | 104 | 9.52 | 8.54 | 0.34 | 0.15 | 0.49 | 90 | 25 | 65 |

| Φ9.52×0.40+0.25-18° | 123 | 9.52 | 8.22 | 0.4 | 0.25 | 0.65 | 40 | 18 | 60 |

| Φ12.00×0.36+0.25-18° | 140 | 12.00 | 10.78 | 0.36 | 0.25 | 0.61 | 40 | 18 | 70 |

| Φ12.70×0.35+0.25-18° | 155 | 12.70 | 11.50 | 0.35 | 0.25 | 0.60 | 53 | 18 | 70 |

| Φ12.70×0.40+0.25-18° | 170 | 12.70 | 11.40 | 0.4 | 0.25 | 0.65 | 53 | 18 | 70 |

| Φ12.70×0.50+0.25-18° | 201 | 12.70 | 11.20 | 0.5 | 0.25 | 0.75 | 53 | 18 | 75 |

| Φ12.75×0.36+0.21/0.25-20° | 150 | 12.75 | 11.53 | 0.36 | 0.25 | 0.61 | 48 | 20 | 70 |

| Remark:These are common sizes which the company is making,and unusaal sizes with special requirement can be tailor-made against order. | |||||||||

the inside surface area increases 70~100% than that of the same specification of plain copper tube, the heat transfer coefficient is about 1.8~2.0 times of that of same specification of plain tube.

- Q:If I have a square inch of copper plate 1/8 of an inch thickANDIf I have a square inch of Pyrex glass plate 1/8 of an inch thickAND I apply a flame to one side of each of for 30 seconds.then I turn off the flame to both of themWhich will be the cooler in 10 seconds?The Pyrex or the copper?

- copper is the better thermal conductor, so the pyrex will be cooler. thermal conductivity of copper is 401 W/mK thermal conductivity of glass is 1.05 W/mK .

- Q:Nearly all the copper piping that goes to my taps (under sinks, etc) looks brown/tarnished and is very tough (I have removed some and it was not easy to bend). I have come across quite a bit of 1/2 annealed copper tubing. It is new and shiney, and quite easy to bend with my bare hands. Is this suitable to use for replacing old plumbing pipes? Is there anything I‘d need to be aware of?Thanks very much.

- It serves the same purpose although you might have problems passing it thru the frame in straight line

- Q:I always thought it was Imperial Brass Mfg. in Chicago, Ill. back in the early 1930‘s. Someone recently told me they thought Reed Mfg. invented them in 1886. Anybody have any concrete proof and or links to find out the real scoop.

- I have no idea what a tube cutter is. my pipe cutter I have are for PVC pipes, I doubt it can cut metal. Well, if you own a good shotgun, take it to a gunsmith. if you own some cheap one like mine, where unless I break it the value couldn't possibly get any lower, DIY cut. If your shotgun is for fun shooting, you don't need to re-crown the muzzle. Not crowning will reduce accuracy, generally unless you're hunting/trap shooting with it, it doesn't really matter. cutting down a barrel with a hacksaw is exactly what it is. use a bench vise to hold the barrel (remove it from the shotgun), measure out 19 inches or just a bit more, check to make sure even with the cut made the shotgun will still meet length requirements. 18 barrel and 26 overall. use a hacksaw and cut as straight as possible thru the barrel. The steel is surprisingly soft. I use my cheap used $100 shotgun for plinking use. the barrel I cut down to 18.75. I used a hacksaw. The cut isn't square to the barrel, oh well. I used a dremel tool to clean up the edges. then a file to make the sanding marks smooth.

- Q:I noticed a small wet patch in my basement drop cieling. I removed the panel to find a pipe that seems to lead from my toilet to the sewer line leading out of the house. It is at a point where the pipes join and there is a seam. Do I sodder? Do I patch?? If anyone knows how I can fix this please HELP!!!

- Not too sure where these guys get their info about copper not being used as drain lines. 30 years ago, everyone who was anyone, wanted nothing but copper for their plumbing piping, both water supply and drainage. Now 30 years later, they're finding that leaks, such as yours, develope in the lines, just because they ARE copper and subject to severe corrosion under many different types of circumstances. The drain lines, such as yours, aren't usually that tough to repair, if the leak is in a fairly accessable place in the line. If, as you say, it's coming from a joint, then there are numerous ways to seal it. You could simply smear a layer or two of clear silicone sealant on it and let it dry, or if you're handy with tools and have some experience soldering copper, you could clean around the joint and resolder it, or you could wrap an old bicycle or auto inner tube piece around it and clamp it.

- Q:I have a project due Monday and I have no idea which copper is scarce or abundant. And if you know the number of protons, neutrons, and electrons it contains tha would a big help to!

- Copper is a fairly abundant element. It's atomic number is 29, so 29 protons/29 electrons to find out how many neutrons are in a copper molecule, subtract the atomic number of the element from the atomic weight 63.546 - 29 = 34.546, so 34 neutrons.

- Q:The copper pipe on my water heater is leaking, its not the SS flexable line it‘s the other copper line. How do I replace that one, I‘m a single female with limited funds!

- put coilover, or adjustable system. you can get bigger tire for more comfort

- Q:I need to remove a sharkbite fitting from a copper pipe. I have a female part connected to the copper pipe and need to remove that to attach a male fitting which in turn will attach to a three way valve i bought. The question i have is that i have the removal tube, but the pipe isn‘t long enough in the back for me to grab and twist with the removal tool. Can I use a crescent wrench to mimic the turning action on the back, or how should I approach this to remove the sharkbite fitting? Thanks.

- Removing your pipe from a Sharkbite? fitting is simple with these tongs Step #1:[Tong removal] Grip the Sharkbite? fitting with the tongs, squeeze the Sharkbite? fitting depressing the release ring Step #2:[Pipe Inserted] Rotate the pipe 90°, rotate again and simultaneously remove the pipe from the fitting

- Q:I‘ve noticed that if the pipe bends at all coupling, it leaks. Now, I can force the pipe to stay straight and that‘s not a problem. My concern is, does this mean that the coupling is not fitted properly, or do they just do this if the pipe is not straight at the joint? I just want to be sure that when it get cold outside again that it‘s not going to start leaking in the middle of the night.

- Sounds like your emissions sensor is sending a bad signal this could make the care send an inappropriate combination of gas and air into the engine causing it to burn incorrectly this could be your problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

COPPER TUBES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords