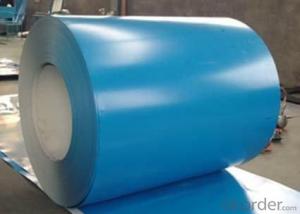

RAL Scale Prepainted Rolled Steel Coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of RAL Scale Prepainted Rolled Steel Coil for Construction Roof

Description of RAL Scale Prepainted Rolled Steel Coil for Construction Roof

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of RAL Scale Prepainted Rolled Steel Coil for Construction Roofg

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of RAL Scale Prepainted Rolled Steel Coil for Construction Roof

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of RAL Scale Prepainted Rolled Steel Coil for Construction Roof

Product | RAL Scale Prepainted Rolled Steel Coil for Construction Roof |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of RAL Scale Prepainted Rolled Steel Coil for Construction Roof

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each color. And we could give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your can offer the better price we can provide.

2. How long can we receive the product after purchasing?

Usually within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15- 25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the major challenges faced by steel coil manufacturers?

- The major challenges faced by steel coil manufacturers can be categorized into several key areas. 1. Raw Material Costs: One of the primary challenges is the fluctuating prices of raw materials, such as iron ore and coal, which are essential for steel production. Manufacturers have to constantly monitor and adjust their pricing strategies to mitigate the impact of these fluctuations and maintain profitability. 2. Global Competition: Steel coil manufacturers face intense competition from both domestic and international players. Globalization has led to an increase in the availability of steel coils from various regions, making it crucial for manufacturers to differentiate themselves through quality, pricing, and customer service to remain competitive. 3. Technological Advancements: The steel industry is constantly evolving and adopting new technologies. Manufacturers need to invest in modern equipment and machinery to improve efficiency, reduce costs, and meet stringent quality standards. Keeping up with technological advancements can be challenging, especially for smaller or less financially stable manufacturers. 4. Environmental Regulations: Steel production is a resource-intensive process that can have a significant impact on the environment. Governments worldwide are imposing stricter regulations on emissions, waste disposal, and energy consumption, which poses a challenge for steel coil manufacturers. Compliance with these regulations requires significant investments in pollution control technologies and sustainable practices. 5. Skilled Workforce: The steel industry requires a skilled workforce with expertise in various areas such as metallurgy, engineering, and operations. However, attracting and retaining skilled employees can be challenging, as the industry faces a shortage of qualified personnel. Manufacturers need to invest in training and development programs to ensure a competent workforce and maintain operational excellence. 6. Economic Volatility: Steel coil manufacturers are highly sensitive to economic fluctuations. During periods of economic downturns, demand for steel products decreases, leading to excess capacity and lower profit margins. On the other hand, during economic booms, manufacturers may face challenges in meeting increased demand and ensuring timely delivery. 7. Transportation and Logistics: Steel coils are bulky and heavy, making transportation and logistics a significant challenge for manufacturers. Optimizing supply chain management, coordinating with freight partners, and ensuring timely delivery of products to customers across various geographies can be complex and costly. In conclusion, steel coil manufacturers face several challenges, including raw material costs, global competition, technological advancements, environmental regulations, skilled workforce requirements, economic volatility, and transportation logistics. Overcoming these challenges requires proactive strategies, continuous improvement, and a focus on innovation to remain competitive in the industry.

- Q:How are steel coils protected during shipping?

- Steel coils are typically protected during shipping by being wrapped in a moisture-resistant material such as plastic or wax paper. They are also often secured with steel straps or bands to prevent shifting or damage during transit. Additionally, wooden or metal cradles are used to provide support and stability while in transport.

- Q:How are steel coils used in the production of solar panels?

- Steel coils are not directly used in the production of solar panels. However, steel may be used as a component in the structural framework or mounting systems of solar panels to provide stability and support.

- Q:What are the common methods of handling steel coils during production?

- During production, steel coils can be handled using a variety of methods. These methods have been developed to guarantee the secure movement and storage of the coils, as well as to streamline the processing. 1. Forklifts: Within a production facility, forklifts are frequently employed to transport steel coils. Equipped with specialized attachments like coil rams or coil hooks, forklifts securely grip the coils, making transportation effortless. They are especially useful for moving coils over short distances or between different areas of the production floor. 2. Overhead cranes: Another commonly used method for handling steel coils is through the use of overhead cranes. These cranes are usually fixed on rails and can span the entire length of the production facility. By utilizing lifting devices such as C-hooks or magnets, overhead cranes can securely lift and transport the coils. They are particularly beneficial for moving large or heavy coils over longer distances. 3. Coil cars: Coil cars are specialized vehicles mounted on rails, specifically designed to transport steel coils within a production facility or between different areas of a steel mill. These cars are equipped with adjustable arms or forks that can be positioned to securely hold the coils. Coil cars are often utilized when there is a need to move large quantities of coils simultaneously. 4. Coil racks: To store steel coils in a vertical position, coil racks are employed. Constructed from heavy-duty steel, these racks are designed to securely hold multiple coils. They are commonly found in warehouses or storage yards, maximizing space while allowing easy access to the coils. 5. Coil trailers: For long-distance transportation of steel coils, specially designed trailers known as coil trailers are used. These trailers incorporate built-in coil cradles or bunks that securely hold the coils during transit. They often feature adjustable or removable coil racks to accommodate different sizes or configurations of coils. In summary, various specialized equipment such as forklifts, overhead cranes, coil cars, coil racks, and coil trailers are commonly used to handle steel coils during production. These methods prioritize worker safety and coil integrity while promoting efficient movement and storage throughout the production process.

- Q:What are the different types of steel coatings for coil protection?

- Some of the different types of steel coatings for coil protection include galvanized coatings, metallic coatings, organic coatings, and polymer coatings.

- Q:What are the common coil loading and unloading procedures?

- Common coil loading procedures involve using cranes or forklifts to lift and position coils onto trailers or flatbed trucks. The coils are typically secured using straps, chains, or coil racks to prevent shifting during transportation. During unloading, the same equipment is used to carefully lift and remove the coils from the truck, ensuring safety and stability throughout the process.

- Q:What are the different methods of annealing steel coils?

- There are several different methods of annealing steel coils, each with its own advantages and applications. The main methods include full annealing, process annealing, and spheroidize annealing. Full annealing is the most common method and involves heating the steel coils to a temperature above its critical point, typically between 800 and 900 degrees Celsius (1472 and 1652 degrees Fahrenheit), and then slowly cooling it down in a controlled manner. This process helps to refine the grain structure of the steel, making it softer and more ductile. Full annealing is often used to relieve internal stresses, improve machinability, and enhance the overall mechanical properties of the steel. Process annealing, also known as subcritical annealing or stress relief annealing, is a method used to reduce the hardness and brittleness of steel coils. It involves heating the coils to a temperature below its critical point, typically between 550 and 650 degrees Celsius (1022 and 1202 degrees Fahrenheit), and then slowly cooling them down. This process helps to relieve internal stresses that may have developed during previous manufacturing processes, such as cold working or welding. Process annealing is commonly used to improve the formability and toughness of steel coils. Spheroidize annealing is a specific type of annealing that is used to soften high carbon and alloy steels. It involves heating the steel coils to a temperature slightly below its critical point, typically between 650 and 700 degrees Celsius (1202 and 1292 degrees Fahrenheit), and then holding it at that temperature for a prolonged period of time. This allows the carbides within the steel to transform into rounded or spheroidal shapes, which increases the steel's machinability and ductility. Spheroidize annealing is often employed in the production of cutting tools, bearings, and other applications where improved machinability is desired. In addition to these main methods, there are also variations and specialized techniques that can be used for specific purposes, such as recrystallization annealing, intercritical annealing, and solution annealing. Each method has its own set of parameters and temperature ranges, and the choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and the intended application of the steel coils.

- Q:How are steel coils used in the manufacturing of conveyor belts?

- Steel coils are used in the manufacturing of conveyor belts as they provide strength, durability, and flexibility to withstand the heavy loads and continuous movement experienced in conveyor systems. The coils are shaped into a continuous loop, forming the core structure of the belt, which is then covered with various materials to enhance grip, prevent slipping, and improve overall performance.

- Q:What are the different methods of surface cleaning for steel coils?

- There are multiple options available for cleaning the surface of steel coils, and the choice of method relies on specific requirements and conditions. 1. Mechanical Cleaning: To physically eliminate dirt, rust, or other contaminants from the surface of steel coils, mechanical tools like wire brushes, sanding discs, or abrasive pads are used. It is commonly employed for light cleaning and can be done manually or with the assistance of automated equipment. 2. Chemical Cleaning: By using various cleaning agents or solvents, chemical cleaning dissolves or loosens contaminants from the surface of steel coils. This method effectively removes oil, grease, or stubborn dirt. The selection of chemicals depends on the type of contaminants and the desired level of cleaning. It is crucial to adhere to safety guidelines and use appropriate protective equipment when utilizing chemical cleaners. 3. Power Washing: High-pressure water jets are utilized in power washing or pressure washing to eliminate loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for extensive cleaning and can be combined with chemical cleaners for better results. Adjusting the water pressure according to the surface type and using suitable nozzles is important to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves immersing steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process eliminates scale, oxides, and other impurities from the steel's surface. Pickling is frequently employed for heavy-duty cleaning and preparing steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning employs an electric current to remove contaminants from the surface of steel coils. The coils are submerged in an electrolyte solution, and the application of direct current causes the contaminants to dissolve or dislodge. This method is highly effective for eliminating rust or corrosion and can be used in conjunction with other cleaning methods. When choosing the appropriate surface cleaning method, it is vital to consider factors like the type and condition of the steel coils, the required level of cleanliness, and any specific industry standards or regulations. Regular maintenance and cleaning are essential to ensure the longevity, performance, and corrosion resistance of steel coils.

- Q:How do steel coils perform in high-pressure applications?

- Due to their robust and durable nature, steel coils are highly effective in high-pressure scenarios. The exceptional tensile strength of steel enables it to endure immense pressure without any distortion or breakdown. Moreover, steel coils are specifically engineered to retain their shape and structural integrity even under the most extreme pressure, making them ideal for deployment in a wide range of high-pressure applications such as hydraulic systems, pressure vessels, and industrial machinery. Furthermore, the exceptional resistance of steel coils to corrosion and high temperatures further augments their performance in high-pressure environments. These qualities, coupled with their reliability and capacity to withstand high pressure, render steel coils the preferred choice for industries seeking resilient and efficient equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

RAL Scale Prepainted Rolled Steel Coil for Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords