Plastic Pipe Crusher Screenless Crusher Granulator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Plastic crusher

plastic crusher machine can crush many kinds of plastic and rubber plastic.such as plastic special-shaped material, tube, rod, tire, film, waste rubber products.

This plastic crusher machine is suitable for crushing plastic bottle and film, this strong plastic crusher is made of strong welding steel, the crushing chamber has two parts with hydraulic device, it is easy to open the cover.

2.Specification of Plastic crusher

.With unique designed blade base,blades material can be customized according to customer requirements.

.Easy to operate and simple in replacement of cutter blades.

.Cutter blades are resistant to wear and tear.

.Removable screen mesh is easy to install or disassemble for cleaning and changing colors.

.Motor with overload protection device.

.Using electrical control security design to ensure the safety of your personnels.

.Noise reduction insulation for machine body or outside sound insulation roon is available by optional order.

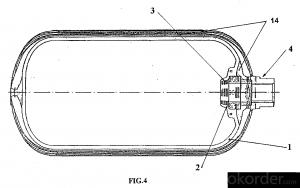

3.Images of Plastic crusher

4. Features of Plastic crusher

, High performance, strong powerful and high speed crushing.

, Motor with overload protection device.

, Supply chain environmental protection system, ensure safe operation.

, Easy disassembly design, convenient clean-up and repair.

, Minicomputer with a four-wheel for easy mobility.

, More than 20HP plastic crusher is equipped with cooling system.

, Suitable for recycle and restore of all kinds of plastic, particulary for various hard plastic, e.g. blow molded products and shoel last.

, HGY plastic claw crusher series are easy to operate and simple replace of cutters blades, well designed of cutter base, cutter blades are able to disperse bearing force & increase the power effectively of each cutter & reduces ware and tear, fully installed withelectrical safety devices. Double wall hopper designed installed with soundproof material, low electricity consumption and durable.

5. FAQ of plastic crusher

. The standard voltage 380v-3phase-50hz voltage, if the supply power for your location using if not this, please tell us in advance, we can change the voltage according to your using, eg: 220v/280v/380v/415v/480v-3phase-50Hz/60Hz and so on.

. The screen mesh is the standard size, if you want change it, we can customize it for you.

. MOQ: 1set

. Payment: T/T, 50% advance, 50% before shipping

. Warranty: 12 months

. Packing requirement: International wooden packing

.Which plastic material will you need to crush, pet bottle, pvc pipe, plastic film, profile or others(it will be best if you can provide the pictures)?

.How many kg/h material do you need to crush(100kg/h, 200kg/h..... )?Or you can provide the power you need.

- Q:Is environmental protection approved for plastic granulation?

- A project does not require EIA, and the EIA is a report or a report form, according to the State Environmental Protection Department's "construction project environmental impact assessment classified management list" of the coming.

- Q:how much the price, I hope to know a friend told me Oh, thank you ah!

- Wuxi Suzhou Qingfeng Suzhou Yangming good Mika Suzhou fine on some companies are using their production line granulator.

- Q:How about the granulator?

- Our company absorb domestic and foreign advanced technology and experience, in strict accordance with the national requirements of GMP design, development, production, installation and service in one, and in strict accordance with the ISO9001 international quality system standards implementation, to ensure product quality.

- Q:how about the market demand, which kinds of particles are usually divided? Which particle has a higher profit margin?

- First, the salesman's task is according to customer requirements and designers to cooperate with the printing program, and confirmed by the customer. Raw materials for customers are generally: 1, Wen Dang (not necessarily standard). 2, in kind. 3 oral or written product description. To be as detailed as possible, if the conditions, so that customers and designers face to face, easier to complete the design faster. Two, according to the salesman: 1, the customer has confirmed the program (usually a single version of the design). 2, production quantity and economic benefits. 3, printing machines and other production equipment requirements (first on the boot). Process for production and imposition jointly determine the production department, business department, and the scheme to allow the designer to perform. Three, according to the technical scheme designer imposition, film output, proofing proofing confirmation print version of the housing.

- Q:Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken. There is also a two axis of its own teeth rotation, it may be broken bearings.

- Q:How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q:Dry granulator and wet granulation machine what is the difference

- The so-called wet granulation is generally back to the use of materials, granulation is not afraid of a little moisture

- Q:What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q:How much will it cost to invest in the recycled plastic particle production line?

- Depends on the output, from about 60 thousand to millions of start.

- Q:How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Pipe Crusher Screenless Crusher Granulator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords