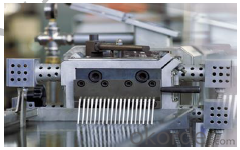

Plastic Granulator for Parallel Twin Screw Extruder Pelletizing Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Parallel Twin Screw Extruder Pelletizing Machine Line Characteristics:

Capacity: 50-500 kg per hour

ABB or Simens motor, Omron or Simens electrical parts

Material: Carbon steel and stainless steel

CE Standard; Provide Turn Key Solution.

Optional design for customer: PLC control, no net filter extruding, electrical parts brand, etc.

Parallel Twin Screw Extruder Pelletizing Machine Line Pelletizing Type:

Hot face cutting granulator

Water ring cutting granulator

Water cooling granulator

Other pelletizing type

Parallel Twin Screw Extruder Pelletizing Machine Line Application:

PP nonwovens recycling granulator

PE PET flakes recycling granulator

Filling material pelletizing, master batch pelletizing

Recycle PP, PE pipe pelletizing

Parallel Twin Screw Extruder Pelletizing Machine Series:

Model | SJ-35 | SJ-50 | SJ-65 | SJ-75 | SJ-95 |

Screw diameter(mm) | 35.6 | 50.5 | 62.4 | 70.5 | 93 |

L/D | 32,36,40,44,48 | ||||

Main motor power(kw) | 15 | 37 | 55 | 90 | 150 |

Screw rotation speed(r/min) | 600 | 600 | 600 | 600 | 600 |

Torque | 115 | 415 | 680 | 995 | 2380 |

Plasticization capability(kg/h) | 50-80 | 80-150 | 150-300 | 250-500 | 450-800 |

- Q:Is environmental protection approved for plastic granulation?

- A project does not require EIA, and the EIA is a report or a report form, according to the State Environmental Protection Department's "construction project environmental impact assessment classified management list" of the coming.

- Q:How should maintain plastic granulator

- Always clean the plastic residue in the case so as not to use the card machine. Clean with alcohol or gasoline. Keep lubrication of relative movement parts.

- Q:Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken.

- Q:Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- The so-called wet granulation is generally back to the use of materials, granulation is not afraid of a little moisture exists.

- Q:May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q:How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q:Dry granulator and wet granulation machine what is the difference

- General plastic and water will degrade the performance of plastic degradation will make significant decline, affect the product performance, so the new material is generally not wet, extrusion is to make the plastic particle drying.

- Q:The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The granulator is a kind of forming machine which can make material into a specific shape. Widely used in chemical, petrochemical, pharmaceutical, food, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics and other fields. According to the structure and working principle and divided into CF type rotary belt type condensing granulator flat twin screw extruder drying drum roll production machine dry granulating machine (referred to as the roll granulator granulator) on tooth disc vacuum condensation granulator. The granulating mechanism has the advantages of quick granulation and good effect. The filter screen for designing special holes is carefully screened, and the friction filter rod can crush, sieve and filter the solid particles, and is widely used in the pharmaceutical, chemical and food industries. Instead of swing granulator, the utility model is a new generation of granular equipment.

- Q:What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q:How much will it cost to invest in the recycled plastic particle production line?

- Depends on the output, from about 60 thousand to millions of start.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Granulator for Parallel Twin Screw Extruder Pelletizing Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords