Plastic Granulator for PET Flakes Granulation Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Raw material & Final product:

Raw material & formulation | PET materials |

Final product & Output capacity | 400kg/h |

Description of final product | 1. PET granules |

2. Work condition:

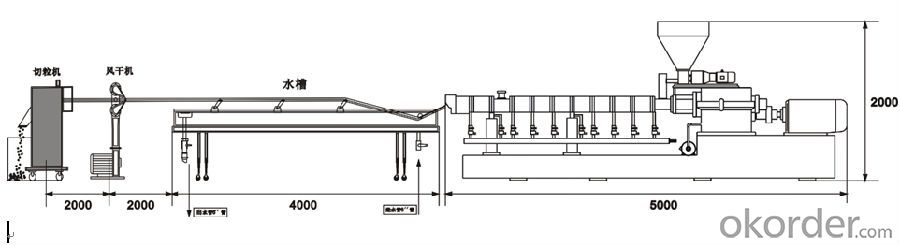

Warehouse/Workshop | Dimension (M*M*M): 15(L)×3(W)×3(H); If workshop is small, turn the machine around. |

Power supply & Installation power | 3-phase, 380 V, 50 Hz; (do as customer's request) |

Wire/cables(provide by customer) | Wires/cables from power supply to control cabinet of this production line; all electrical cables from control cabinet to each machine. |

Water supply hose/pipe(provide by customer) | Water supply to machines and pools |

3. Energy consumption:

Installation power | 210Kw ( Actual Consumption 180Kw ) |

Water supply | Consumption: ~1 tons per hour cycling water. Pressure: 0.6Mpa |

Manpower | 1 Persons |

Equipment List

Item | Name | Specification | Qty | Total Price |

1 | Parallel Extruder JH75 | 132+61Kw | 1 pc. |

USD 64200 FOB Shanghai CE Standard

|

2 | Hydraulic Screen Exchanger | 2.2Kw | 1 pc. | |

3 | Head | / | ||

4 | Water Cooling Slot | / | 1 pc. | |

5 | Air Blower Dryer | 1.5Kw | 1 pc. | |

6 | Granulator | 7.5Kw | 1 pc. | |

7 | Electrical Cabine | / | 1 pc. |

Business Term

DELIVERY | : | FOB Shanghai, |

PRICE | : | 64200 USD |

DELIVERY TIME | : | 30 Days |

OFFER VALIDITY | : | 30 Days |

TERMS OF PAYMENT | : | 30% of down-payment by T/T. Balance 70% T/T before delivery |

WARRANTY | : | Mechanical parts & Electrical parts : 12 months for parts considered by the manufacturer to be defective. |

INSTALLATION | : | Two persons are needed for commissioning; The buyer afford buy and back round ticket, accommodation, and 50usd allowance per person. It takes 10days installation. |

- Q:how much the price, I hope to know a friend told me Oh, thank you ah!

- We have been committed to the research and development of plastic extrusion machinery technology, the market for plastic extruder universal low productivity and short service life, high power consumption, in the mechanical design, according to the needs of different customers and different raw materials, developed separation screw, high mixing screw, machine tube technology KIV and with the use of hard tooth, mute type reducer, effectively solve these problems, the effective capacity of extruder with same specification and same type of plastic will increase from 20% to 30%, the actual power consumption is reduced by about 20%, the real implementation of the high capacity, long service life and low power consumption.In some developed countries, foreign enterprises and joint ventures on the type of environmental protection requirements, including noise control, exhaust gas treatment, closed the smoke, dust, and different frequency voltage, motor, we can achieve the design and manufacturing requirements.We follow the requirements of ISO9001 quality control system, establish a complete and standardized internal technical standards and quality control procedures, control point from the whole process of pre-sales service to product design, manufacturing, customer service service, to create a full range of its product quality, we have a number of years engaged in plastic granulator research and development, manufacturing and service a professional engineering team and staff, provide a solid guarantee for the customer confidence.

- Q:How should maintain plastic granulator

- This is the Sichuan Universiade presses to inform customers of the machinery, is sure to play well, there is oil in the binding site, keep the machine clean, there will be water in the unit, shutdown to wipe water, also want to take the blade oh

- Q:Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken.

- Q:How to solve the noise of plastic granulator

- I suggest you cover your ears and solve it.

- Q:Waste plastics granulation EIA Report Sample

- The book is very thick and the EIA form is very simpleYou directly find qualified to do the EIA, for you to do

- Q:May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q:How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q:The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The granulator is a kind of forming machine which can make material into a specific shape. Widely used in chemical, petrochemical, pharmaceutical, food, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics and other fields. According to the structure and working principle and divided into CF type rotary belt type condensing granulator flat twin screw extruder drying drum roll production machine dry granulating machine (referred to as the roll granulator granulator) on tooth disc vacuum condensation granulator. The granulating mechanism has the advantages of quick granulation and good effect. The filter screen for designing special holes is carefully screened, and the friction filter rod can crush, sieve and filter the solid particles, and is widely used in the pharmaceutical, chemical and food industries. Instead of swing granulator, the utility model is a new generation of granular equipment.

- Q:What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Look at the product use and performance parameters, it is necessary to add some,

- Q:What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Granulator for PET Flakes Granulation Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches