Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 19.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction

- Up to 20.0% efficiency, one of the highest performing mono crystalline cells on the market

- Three bus bars boosts current collection over the entire cell area, leading to higher fill factors

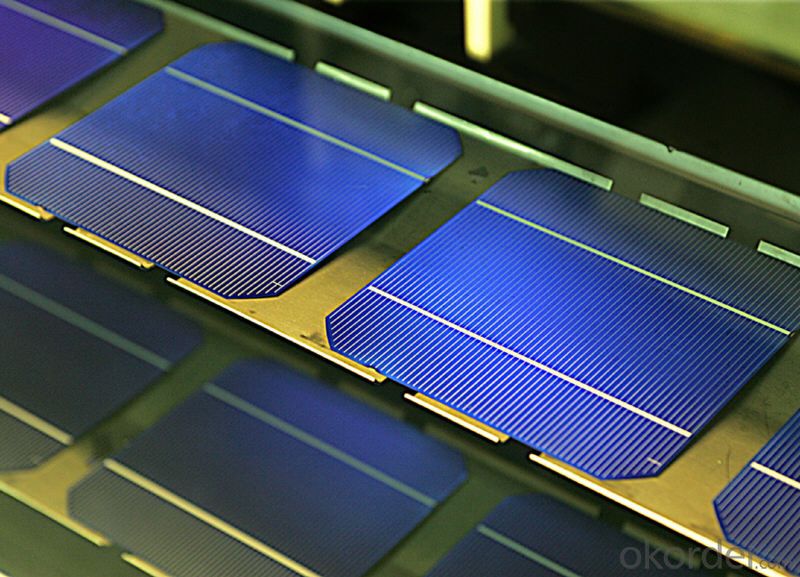

- Blue anti-reflecting coating allows more sunlight be captured and converted to electricity

- Finer, closer fingers improves charge collections for improved energy yield

- Lower light-induced degradation leads to greater power output over the entire module lifetime

- All solar cells are tightly classified to optimize output of module

- Maximum yield and longevity due to hotspot prevention

- Premium appearance results in a highly uniform and aesthetically appealing module

Specification

- Product Mono-crystalline silicon solar cell

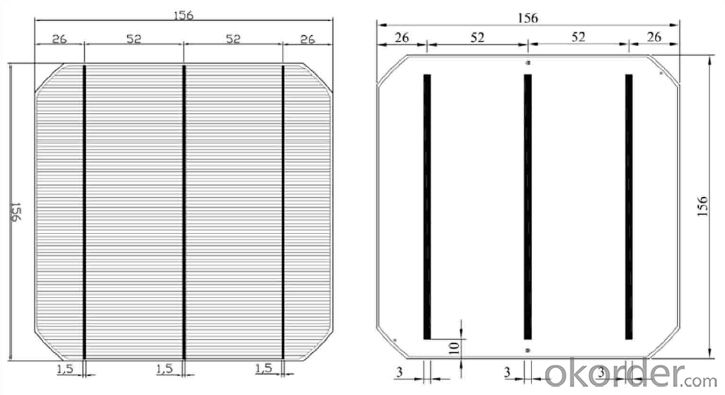

- Dimension 156 mm x 156 mm ± 0.5 mm

- Thickness 200 μm ± 30 μm

- Front 1.5 ± 0.1 mm busbar (silver)

- Silicon nitride antireflection coating

- Back 3.0 mm continuous soldering pads (silver)

- Back surface field (aluminum)

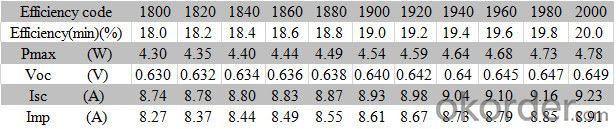

Electric performance parameters

- Testing conditions: 1000 W/m2, AM 1.5, 25 °C, Tolerance: Efficiency ± 0.2% abs., Pmpp ±1.5% rel.

- Imin : at 0.5 V

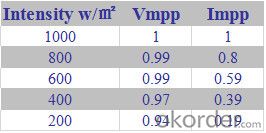

Light Intensity Dependence

Soldering Ability

- Peel Strength: > 1.0 N/mm (Pull soldered ribbon from busbar in 5 mm/s of 180°)

Dimension Figure

Quick Response

- Any time and anywhere, reply clients' email and solve all problems happen in the work at the first time.

- Remove clients doubts and offer the best solution at the first time.

- Give our clients the lastest news of the photovoltaic, update the newest stock informtion.

Production and Quality Control

- Precision cell efficiency sorting procedures

- Stringent criteria for color uniformity and appearance

- Reverse current and shunt resistance screening

- ISO9001,ISO14001 and OHSAS 18001,TUV Certificated

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

5. Q: Do you accept custom design on size?

A: Yes, if the size is reasonable.

6. Q: How can I be your agent in my country?

A: Please leave feedback. It's better for us to talk about details by email.

7. Q: Do you have solar project engineer who can guide me to install system?

A: Yes, we have a professional engineer team. They can teach you how to install a solar system.

- Q:What is the meaning of a cleaning in a semiconductor silicon wafer process? RCA?

- () APM (SC-1): NH4OH/H2O2 /H2O 30 ~ 80 DEG C due to the action of H2O2, the surface of the silicon wafer has a natural oxide film (SiO2), which is hydrophilic, and the surface of the silicon wafer can be soaked with the cleaning liquid. Because the natural oxide layer on the surface of silicon wafer and the Si on the surface of silicon wafer are corroded by NH 4OH, the particles attached to the surface of the silicon wafer will fall into the cleaning liquid, so as to achieve the purpose of removing particles. At the same time, the H2O 2 forms a new oxide film on the surface of the oxidized silicon wafer when the NH4OH is etched on the surface of the silicon wafer.

- Q:How is the voltage output of a solar silicon wafer regulated?

- The voltage output of a solar silicon wafer is regulated through the use of various components in a solar panel system. These components include a charge controller or regulator, which monitors and regulates the voltage and current flowing from the solar cells. It ensures that the voltage output remains within a safe and optimal range for the connected devices or battery being charged. Additionally, voltage regulators or inverters may be employed to further regulate and convert the DC voltage output of the solar cells into AC voltage suitable for use in household or grid-connected applications. Overall, these regulatory components play a crucial role in maintaining the stability and efficiency of the voltage output from a solar silicon wafer.

- Q:Can solar silicon wafers be used in military applications?

- Yes, solar silicon wafers can be used in military applications. They can be utilized in various military technologies such as solar-powered equipment, communication systems, surveillance devices, and even in the development of solar-powered drones or vehicles for military use. The use of solar silicon wafers in military applications can provide a renewable and reliable source of energy, reducing dependence on traditional fuel sources and enabling more sustainable operations in the field.

- Q:How are solar silicon wafers packaged for shipping?

- Solar silicon wafers are typically packaged for shipping by placing them in anti-static foam trays or boxes. These trays or boxes are designed to securely hold and protect the delicate wafers during transportation. The packaging is often customized to provide cushioning and prevent any damage or breakage during transit.

- Q:What is the purpose of a busbar in a solar silicon wafer?

- The purpose of a busbar in a solar silicon wafer is to collect and distribute the electrical current generated by the wafer's photovoltaic cells.

- Q:How is a solar silicon wafer connected to other components in a solar panel?

- A solar silicon wafer is typically connected to other components in a solar panel through a process called soldering. Soldering involves using a soldering iron to melt solder, a metal alloy, and then applying it to the connections between the wafer and other components. This creates a strong electrical and mechanical bond, allowing for efficient transfer of electricity within the solar panel.

- Q:How are solar silicon wafers affected by potential-induced degradation?

- Solar silicon wafers are negatively affected by potential-induced degradation (PID). PID occurs when high voltage potential differences between the solar cells and their grounded frames cause leakage currents to flow through the silicon wafers. This leads to a decrease in the power output and efficiency of the solar panels over time. PID can significantly impact the performance and lifespan of solar photovoltaic systems, making it crucial to implement preventive measures and use PID-resistant materials and designs to mitigate its effects.

- Q:What is the effect of doping on the bandgap of a solar silicon wafer?

- Doping in a solar silicon wafer can have a significant effect on its bandgap. By introducing impurities, such as phosphorus or boron, into the silicon crystal lattice, the band structure of the material is altered. N-type doping, with elements like phosphorus, introduces extra electrons into the conduction band, reducing the bandgap energy and enabling the absorption of lower-energy photons. P-type doping, with elements like boron, creates holes in the valence band, which also decreases the bandgap energy. Ultimately, doping helps optimize the bandgap of the silicon wafer to match the solar spectrum, enhancing its efficiency in converting sunlight into electricity.

- Q:Are solar silicon wafers affected by electrical surges?

- Yes, solar silicon wafers can be affected by electrical surges. Electrical surges can cause damage to the delicate electronic components within the solar panels, including the silicon wafers. It is important to have proper surge protection measures in place to safeguard the solar panels from potential damage.

- Q:What is the impact of impurities on the performance of solar silicon wafers?

- The presence of impurities in solar silicon wafers can significantly impact their performance. Impurities can alter the electrical properties of the silicon, affecting the efficiency of the solar cell. For example, certain impurities can create energy barriers or recombination centers, reducing the overall conversion efficiency of the solar cell. Additionally, impurities can also lead to unwanted optical absorption, reducing the amount of light that can be absorbed and converted into electricity. Therefore, minimizing impurities and ensuring high-purity silicon wafers is crucial for maximizing the performance and efficiency of solar cells.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mono Solar Cells156mm*156mm in Bulk Quantity Low Price Stock 19.8

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords