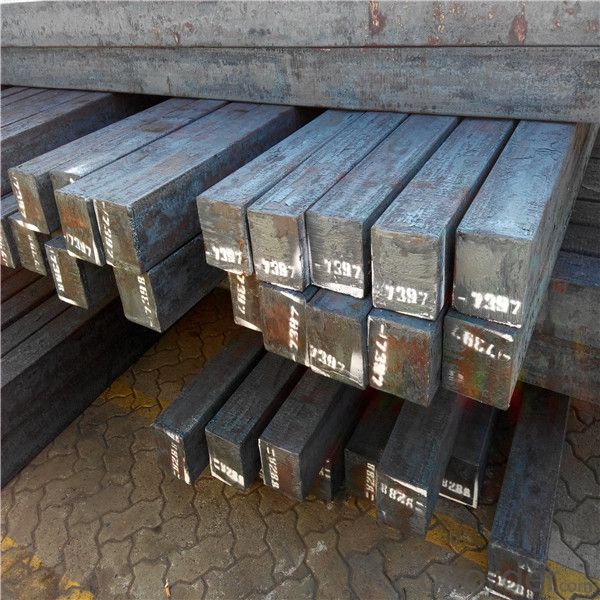

Mild steel billet price low but high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular

and abnormity of several kinds of, mainly related to the shape of rolled products.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Size :100mm to 165mm

Length:6~12meters

Grade: Q195/Q215/Q235/Q275

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What are the specifications for steel billets used in the defense industry?

- The defense industry utilizes different specifications for steel billets depending on the specific application and requirements. However, there are certain common specifications that are generally followed. First and foremost, high strength and durability are necessary for steel billets used in the defense industry to withstand extreme conditions and potential impacts. They typically need to possess a high tensile strength, usually above 500 MPa, and exceptional toughness to resist fracture or deformation. Moreover, good corrosion resistance properties are essential for steel billets used in the defense industry. This is crucial to ensure the longevity and reliability of defense equipment and structures, particularly when exposed to harsh environments or corrosive elements. Regarding dimensional specifications, precise dimensions and tolerances are typically required for steel billets used in the defense industry. This ensures compatibility and proper fitment during the manufacturing process and assembly of defense equipment. Additionally, strict quality control measures are implemented for steel billets used in the defense industry. They must comply with various industry standards and certifications, such as MIL-SPEC (Military Specifications), to guarantee the highest level of quality, performance, and safety. Finally, depending on the specific application, additional specifications such as heat treatment requirements, chemical composition, and non-destructive testing may also be specified for steel billets used in the defense industry. It is important to note that the exact specifications for steel billets used in the defense industry may vary based on the specific requirements of each defense project. Therefore, it is essential to consult the relevant defense industry standards and guidelines for accurate and up-to-date specifications.

- Q:What are the different types of steel billets used in the aerospace industry?

- In the aerospace industry, various types of steel billets are used, including stainless steel, tool steel, and high-strength alloy steel. These types of steel are chosen for their specific properties, such as corrosion resistance, high temperature strength, and superior mechanical properties.

- Q:What are the main steel billet producing countries?

- China, India, Russia, Japan, and the United States are the primary countries responsible for the production of steel billets. China takes the lead as the largest producer, accounting for approximately half of the global output. Following closely behind is India, which has also emerged as a major player in the steel industry. Russia, known for its abundant reserves of iron ore and coal, is also a significant producer of steel billets. Japan, being a highly industrialized nation, has a well-established steel industry and makes a significant contribution to global production. Lastly, the United States, with its advanced technology and large steel mills, also plays a significant role in steel billet production. These countries not only cater to domestic consumption but also export to meet the global demand for steel products.

- Q:How do steel billets contribute to the overall durability of a product?

- Steel billets are an essential component in the manufacturing process of various products, and their contribution to the overall durability cannot be overstated. These billets are semi-finished steel products that are used as raw material for further processing in industries like construction, automotive, and manufacturing. One of the primary reasons why steel billets contribute to the overall durability of a product is their superior strength and toughness. Steel is known for its exceptional mechanical properties, including high tensile strength and resistance to deformation, making it an ideal choice for applications that require durability. By using steel billets as the starting material, manufacturers can ensure that the final product will possess the necessary strength to withstand heavy loads, impacts, and other external forces. Moreover, steel billets have excellent corrosion resistance. Steel, when properly processed and treated, can resist rust and other forms of corrosion caused by moisture, chemicals, or environmental factors. This corrosion resistance greatly enhances the durability of the final product, as it prevents degradation and extends the lifespan. Another advantage of using steel billets is their versatility in terms of customization. Manufacturers can shape and form the billets into various sizes and dimensions according to the specific requirements of the product. This flexibility allows for the production of components that perfectly fit together, reducing the risk of weak points or vulnerabilities in the overall structure. Additionally, steel's malleability and ductility enable it to be easily molded and welded, further enhancing the overall strength and durability of the final product. Furthermore, steel billets undergo rigorous quality control measures during the manufacturing process. These measures ensure that the billets meet strict industry standards and specifications, guaranteeing their reliability and consistency. The high-quality steel billets, in turn, contribute to the overall durability of the product by providing a strong and reliable foundation. In summary, steel billets play a pivotal role in enhancing the overall durability of a product. Their exceptional strength, corrosion resistance, versatility, and high-quality attributes make them an ideal choice for industries that prioritize durability. By utilizing steel billets as the raw material, manufacturers can create products that are capable of withstanding demanding conditions, ensuring longevity and customer satisfaction.

- Q:What is the role of steel billets in the construction industry?

- Steel billets are of great importance in the construction industry as they serve as the primary raw material for producing various steel products used in construction projects. These billets, which are semi-finished steel forms, can be hot-rolled or forged into different shapes and sizes like bars, rods, beams, and wire. The primary purpose of steel billets is to provide the necessary strength, durability, and structural integrity to buildings, bridges, and other infrastructure. They are utilized in constructing foundations, columns, beams, and other load-bearing structures where their high tensile strength and resistance to external forces are crucial. Moreover, steel billets are extensively employed in reinforcement applications. They are utilized to create reinforcing steel bars, also known as rebars, which are embedded within concrete structures to enhance their strength and resistance to tension. These rebars play a critical role in preventing cracks and failures in concrete structures, ensuring their long-term stability and safety. Additionally, steel billets are used in the manufacturing of various construction components such as pipes, tubes, and wires. These components are essential for plumbing, electrical wiring, and other utility installations in buildings and infrastructure projects. In conclusion, steel billets are a fundamental raw material in the construction industry. Their versatility, strength, and durability make them indispensable for creating sturdy and reliable structures, reinforcing concrete elements, and manufacturing essential construction components.

- Q:How are steel billets used in the manufacturing of railway components?

- Steel billets play a vital role as a primary raw material in the production of railway components. The billets serve as the initial stage in the manufacturing process, being transformed into a variety of parts including rails, wheels, axles, and structural elements. To commence the transformation, the steel billets undergo heating in a furnace to achieve a specific temperature, making them more malleable and easier to shape. Once heated, the billets are then subjected to a series of rolling mills, gradually taking on the desired form. For instance, in the production of railway tracks, the heated billets are rolled and shaped into long continuous bars known as rails. These rails are subsequently cut to the required length and undergo further processes such as straightening, grinding, and drilling to meet the necessary specifications. Similarly, steel billets are also employed in the manufacturing of railway wheels and axles. The heated billets are rolled and shaped into round bars, which are then subjected to additional processing to form the wheel and axle components. These components undergo further treatments such as heat treatment, machining, and testing to ensure their strength, durability, and ability to withstand the demanding loads and stresses associated with railway operations. Furthermore, steel billets find utility in the production of other railway components such as couplers, buffers, and suspension systems. These billets are shaped and processed according to the specific requirements of each component, ensuring proper functioning and compatibility with the overall railway system. In conclusion, steel billets are an indispensable ingredient in the manufacturing of railway components. Through heating and rolling processes, they are transformed into rails, wheels, axles, and other structural elements. These components then undergo further processing and testing to guarantee their quality, reliability, and adherence to the rigorous standards of the railway industry.

- Q:How do steel billets contribute to the construction industry?

- Steel billets contribute to the construction industry by serving as the raw material for various steel products used in construction. These billets are transformed into beams, columns, rods, and other structural components that provide strength, stability, and durability to buildings and infrastructure. Additionally, steel billets are used in the manufacturing of reinforcements for concrete, enhancing the structural integrity of concrete structures such as bridges, highways, and buildings. Overall, steel billets play a crucial role in the construction industry by providing the necessary materials for safe and reliable structures.

- Q:What are the different types of steel billet heat treatment processes?

- The industry commonly utilizes various steel billet heat treatment processes to enhance the mechanical properties of steel billets, including strength, hardness, toughness, and ductility, to meet specific application needs. Among the different types of steel billet heat treatment processes are: 1. Annealing: This process entails heating the steel billet to a specific temperature and gradually cooling it to room temperature. It aims to alleviate internal stresses and enhance the machinability and ductility of the steel. 2. Normalizing: The steel billet is heated above its critical point and then allowed to cool in still air. Normalizing refines the grain structure of the steel, resulting in improved mechanical properties and uniformity. 3. Quenching: This process involves rapidly cooling the steel billet from a high temperature by immersing it in a quenching medium, such as water, oil, or polymer. Quenching creates a hardened structure, thereby increasing the steel's hardness and strength. 4. Tempering: After quenching, the steel billet is heated to a lower temperature and slowly cooled. Tempering reduces the brittleness caused by quenching and improves the toughness, ductility, and machinability of the steel. 5. Austempering: The steel billet is quenched to a temperature slightly above the martensite transformation range and held at that temperature until it transforms to bainite. Austempering results in a structure with improved strength, toughness, and wear resistance. 6. Martempering: Similar to austempering, the steel billet is quenched into a medium slightly above the martensite transformation range and then held until it cools below that temperature. Martempering produces a structure with enhanced toughness and reduced distortion compared to conventional quenching. These examples represent only a fraction of the numerous heat treatment processes employed for steel billets. The selection of the appropriate process depends on the desired mechanical properties and application requirements of the steel.

- Q:What is the weight of a standard steel billet?

- The weight of a standard steel billet can vary depending on its dimensions, but typically ranges from 1 to 6 metric tons.

- Q:What are the main factors affecting the corrosion resistance of steel billets?

- Steel billets' corrosion resistance is determined by several main factors: the steel's composition, impurities present, surface condition, and the surrounding environment. To begin with, the steel's composition significantly affects its corrosion resistance. Stainless steels, for instance, possess high levels of chromium and other alloying elements that generate a protective oxide layer on the surface, granting excellent corrosion resistance. Conversely, carbon steels have lower resistance due to their increased carbon content and lack of alloying elements. Furthermore, the presence of impurities in the steel greatly impacts its corrosion resistance. Impurities like sulfur, phosphorous, and non-metallic inclusions act as corrosion initiation sites, leading to localized corrosion and reduced overall resistance. Consequently, managing impurities' presence and distribution during steel billet production is vital to improve corrosion resistance. Moreover, the surface condition of steel billets plays a crucial role in their corrosion resistance. A smooth and clean surface supports the formation of a protective oxide layer, acting as a barrier against corrosive substances. Conversely, rough or contaminated surfaces increase corrosion risk due to the larger surface area and potential for localized corrosion. Lastly, the surrounding environment has a significant influence on steel billets' corrosion resistance. Factors such as humidity, temperature, pH, and the presence of corrosive substances like acids, salts, or pollutants can accelerate corrosion. For instance, steel billets in high humidity or exposed to corrosive chemicals are more vulnerable to corrosion compared to those in dry or less corrosive environments. In conclusion, the corrosion resistance of steel billets relies on their composition, impurities present, surface condition, and surrounding environment. Considering these factors during steel billet production and handling is essential to ensure their long-term durability and resistance against corrosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild steel billet price low but high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 16532 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords