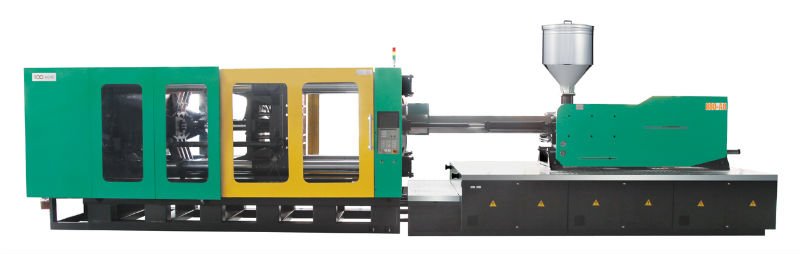

LOG-880A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Shoulder Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG-880A8

Plastic Type: Thermosetting

Automatic: Yes

Injection Weight: 3571g

Injection Rate: 666cm3/s

Clamping Force: 8800KN

Opening Stroke: 1050mm

Packaging & Delivery

| Packaging Details: | one machine in two 40GP containers |

|---|---|

| Delivery Detail: | A week if it's at stock OR a month |

Specifications

high response 2. high precise 3.oil saving 4. water saving 16 long warking life

Details :

| LOG-880A8 | |||||

| International size rating | 7038/880 | ||||

| INJECTION | A | B | C | D | |

| Shot volume | cm3 | 3179 | 3825 | 4750 | 5652 |

| Shot weight | G | 2893 | 3571 | 4321 | 5143 |

| OZ | 102.5 | 126.5 | 153 | 182.1 | |

| Screw diameter | mm | 90 | 100 | 110 | 120 |

| Injection pressure | mpa | 227 | 184 | 152 | 128 |

| Screw L:D ration | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| Screw stroke | mm | 500 | |||

| Screw speed(stepless) | r/min | 0-120 | |||

| CLAMPING UNIT | |||||

| Clamping force | kn | 8800 | |||

| Opening stroke | mm | 1050 | |||

| Platen size | mm×mm | 1530×1530 | |||

| Space between fie bars | mm×mm | 1080×1030 | |||

| Mold fhickness(Min-Max) | mm | 400-1100 | |||

| Max.daylingt | mm | 2150 | |||

| Hydraulic ejection stroke | mm | 300 | |||

| Hydraulic ejection force | kn | 270 | |||

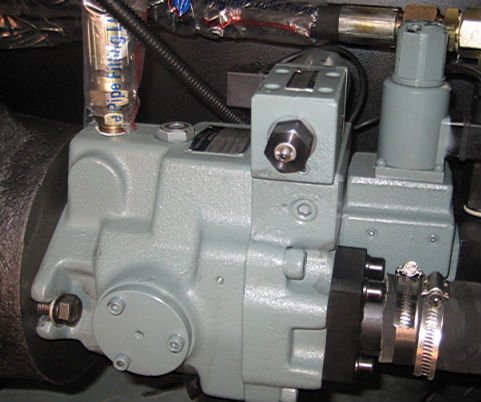

| POWER UNIT | |||||

| Hydraulic system pressure | mpa | 17.5 | |||

| Pump motor | kw | 37+37 | |||

| Heating capacity | kw | 58.45 | |||

| Number of femp confrol zones | \ | 6+ nozzle | |||

| GENERRL | |||||

| Dry-cycle fime | Sec | 8 | |||

| Oil fank capacify | λ | 1900 | |||

| Machine dimensions | m×m×m | 11 X 2.4 X 3.1 | |||

| Machine weight | kg | 48000 | |||

1.template structure of the high-rigidity design,with a bigger clamiping unit. 2. T- slots and conventional screw holes make mold is easy to install. 3 by using our patent bridge structure ,the injection unit will be more stable 4, equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water 5. high-efficiency filter makes the hydraulic oil clean and a long working life 6. the color screen control system, is conventional to operate it.

Products performance and advantages;

1,Clamping parts

The new generation mold locking device and computer emulation optimized parameter makes motions of the moving plate,fixed plate and high rigidity toggle structure,the characteristic of high strength and anti-fatigue is secured.As compared with similar machines,it owns bigger internal spur between tie bars,mold space and mold opening stroke and may process plastic products of bigger size.

2,Computer controller

Professional injection moulding machine controller with software and hardware of industrial standard is convenient to expansion and revision of performance.

Adopting double CPU control makes high speed.

Mainly adopting PID control,the control accuracy reaches±1°.

Has the function of network management,improving efficency.

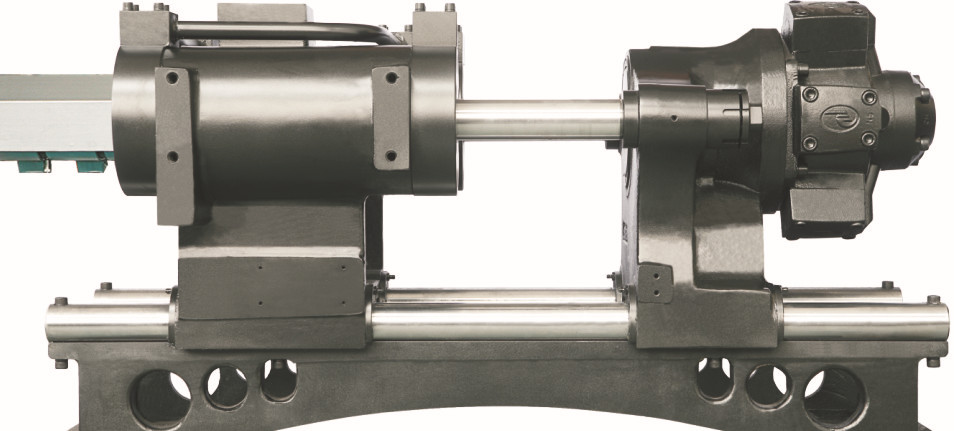

3,The injection unit

Short and forceful double-cylinder injection system is used to ensure the steady injection motion.The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticing capacity and effect.PID temperature control regulate the speed and pressure of injection,pressure keeping,smelting,back pressure and other motions to ensure the quality of formed products and continuation of production.Auto material preparation,drooling proof,and anti cold start lapse functions ensure the high efficent,simple and safe operations.

4,The hydraulic unit

High efficiency,energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy.As comparedwith constant displacement pump,it saves power by 30%~60%.A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerates the speed of machine.Besides,the low oil temperature will prolong the service life of sealing elements.

Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact.Besides,differential mold clamping operation is fitted to ensure high production efficiency.

5,The mould adjusting unit

The automatic mold adjusting device driven by hydraulic motor adopts gear coupling drive,features steadiness,speedinees,high-efficiency and saving mold loading time.

- Q:How many moulds can the 80 ton injection molding machine put down?

- There are two main decisions: meaning opening distance, and two is the distance between the guide pillars.

- Q:Injection molding machine pressure, speed, back pressure unit is what and their relations with other international units

- Pressure injection molding machine, we often talk about the pressure, strictly speaking, the pressure is equivalent to the middle school, which bear the force per unit area, the international regulations, under 1N in the area of 1 square meters (Newton) on the pressure of 1Pa (Pascal), as long as know the multiple relation, it is easy to obtain the pressure (strong the conversion unit):1m=100cm=1000mm1kg = 10N1M (megabit, million) Pa=1MPa=1000k (1000) Pa=1000000PaSo 1MPa=10kg/cm^2=1N/mm^2We often use international non legal units of measurement: 1bar=10^5Pa=1kg/cm^2=0.1MPa (bar) and 1Torr=133Pa (Torr)The pressure gauge of the injection molding machine, the most used is MPa, bar, kgf/cm^2 unit, need to be reminded that, behind the two units is not our statutory units of measurement, but the world especially Europe and the United States is often used, because many components of the injection molding machine for imported components, including the pressure gauge, so we will often see illegal dial pressure gauge measurement units.In the injection molding machine, the injection molding machine pressure and back pressure unit is MPa, speed (actually refers to injection rate), the unit is g/s, or cm^3/s

- Q:Which high-speed machine is stable in domestic injection molding machine?

- Bo machine can also, moderate price, stable performance, I used to produce mobile phones accessories

- Q:In the plastic injection molding machine barrel, why there are so many bubbles?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.Injection molding machine barrel in the bubble is mainly divided into the following categories:Air bubble: the screw speed is too fast or the size of particles, irregular shape of the grinding material and other reasons, causing the raw material feeding time and space, gas is involved in the trip bubble.Water vapor bubbles: raw materials poor drying moisture content is too high, resulting in a large number of water entering the water vapor bubble formation in the barrel.Gas bubbles: raw material heating temperature is too high or too long residence time in the barrel (long heating time) caused by material degradation produce gas, gas bubbles travel.

- Q:Ready to open a small injection molding plantThere are only two machines at the moment, one 160T, one 250TProducts are note PA, PP, PU round (3, 4, 5 inches through)I would like to help you count, if 2 machines 24 hours boot, a month down, the output value of these 2 machines about how much? Thank you, the best way to calculate ~ ~!

- Able to save 1/4 of electricity5 inches with 250T machine to produce, use the mold should be 1 out of 4, cycle count 50 seconds, too specific I don't know how, I just need to calculate method and approximate output value! Because we shipped here, probably a few days 45 to 90 days, I want to see enough money flow! That's the way it is, huh?! --------------------------- know this product with what material, if the PA is up to 30 seconds, you said the other 2 material may be 40 seconds, I didn't see products not determined.

- Q:What should be noticed before the machine is stopped when the injection machine is finished?

- 1, stop feeding (feed off the front barrel, the barrel bottom) has been playing in the finished material2 shut down mold cooling water before stopping,3, press the manual (if not change the mold, stop the mold to the low pressure position, protect the mold)4, mold spray rust inhibitor5, turn off the electric heat6, turn off the power7, cleaning machine sanitation

- Q:What's the injection?

- I. The main contents of the injection molding staff are as follows:1. Responsible for the improvement, preparation and execution of injection molding technology;2. Test the new product and determine the best technological parameters, identify the defects of the product and mould and perfect it;3. Analyze the process of defective products during production and provide solutions and improvement plan;4, the injection molding machine, mold and other equipment maintenance plan formulation and routine maintenance of the implementation, ensure equipment and process safety, quality, ability and utilization rate to achieve the best.5, accept the workshop supervisor's instruction, complete the product quality and quantity, the injection work on time;6, familiar with the process principle, in strict accordance with the quality requirements of the process operation;7. Ensure the achievement of all production target tasks and cooperate with the system review;8. Complete other work assigned by the leader.

- Q:What is a vertical injection molding machine?

- Injection molding machine (referred to as injection machine or injection molding machine) is a thermoplastic or thermosetting material using plastic molding mold made of plastic products of all shapes of the main molding equipment.Injection molding is achieved by injection molding machines and moulds. Although many types of injection molding machine, but no matter what kind of injection molding machine, its basic function has two: (1) heating the plastic to reach the melting state; (2) exert high pressure on the molten plastic to make the shot full of mold cavity.Injection molding machine is usually composed of injection system, mould system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system and so on.Vertical injection molding machines for vertical injection, mostly under 3 tons

- Q:It's the principle of the machine. The pressure is controlled by the oil pressure. How does that speed reach the set value, such as a set of 60 pressure, and the speed is 45, then how does the machine reach the set 45?

- When your speed is set to 45, the controller of hydraulic system flow control valve (or swash plate or servo motor speed / current) outputs a voltage value corresponding to the 45 (current or voltage) signal, controls the hydraulic system pump flow, the greater the flow, the faster the. Set each speed into a corresponding control signal value, control the size of the system traffic, they are linear relationship. The greater the speed you set, the greater the flow will be. So the injection speed is up to this point. (flow is the volume of liquid output per unit time of the pump)Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity. According to the arrangement of injection device and mould locking device, they can be divided into vertical type, horizontal type and vertical horizontal compound type.

- Q:The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- PMMA poly methyl methacrylate (PMMA)PC polycarbonatePOM POMTeflon, PFA PTFE (Te Fulong)CN cellulose nitrate (Sai Lulu)Specific technical parameters,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOG-880A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords