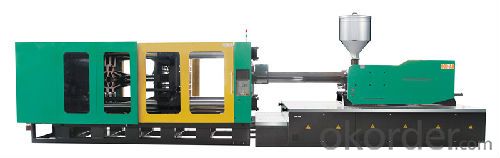

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG900-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 2893-5143g

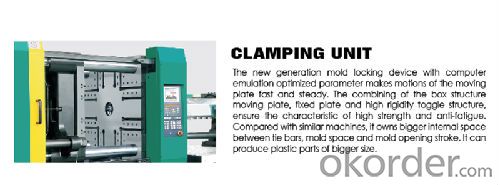

Clamping Force: 9000kn

Opening Stroke: 1050 mm

Power(W): 37+37 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Space between Tie Bar: 1080*1030

Platen size: 1530*1530

Heating power: 58.45 kw

Oil Tank Capacity: 1900 L

Machine weight: 48T

Screw Diameter: 90-100-110-120

Ejector stroke: 300 mm

Ejector force: 270 kn

| INJECTION | LOG900 | ||||

| A | B | C | D | ||

| Shot volume | cm³ | 3179 | 3925 | 4750 | 5652 |

| Shot weight (ps) | G | 2893 | 3571 | 4321 | 5143 |

| oz | 103 | 127 | 153 | 182 | |

| Max injection rate | cm³/s | 540 | 666 | 806 | 960 |

| Screw diameter | Mm | 90 | 100 | 110 | 120 |

| Plasticizing rate | Kg/h | 291 | 378 | 503 | 600 |

| Injection pressure | Mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 22:01 | 22:01 | 20:01 | 18.3:1 | |

| screw speed | r/min | 0-120 | |||

| CLAMPING | |||||

| Clamping force | Kn | 9000 | |||

| Opening stroke | Mm | 1050 | |||

| Platen size | MmXmm | 1530*1530 | |||

| Space between tie bars | MmXmm | 1080*1030 | |||

| Mold thickness (Min-Max) | Mm | 400-1100 | |||

| Hydraulic ejection stroke | Mm | 300 | |||

| Hydraulic ejection force | Kn | 270 | |||

| Power Unit | |||||

| Hydraulic system pressure | Mpa | 17.5 | |||

| Pump motor | Kw | 37+37 | |||

| Heating capacity | Kw | 58.45 | |||

| Number of temp control zones | 6+ (nozzle) | ||||

| GENERAL | |||||

| Dry-cycle time | sec | 8 | |||

| oil tank capacity | L | 1900 | |||

| Machine dimensions | Mxmxm | 11*2.4*3.5 | |||

| Machine weight | kg | 48000 | |||

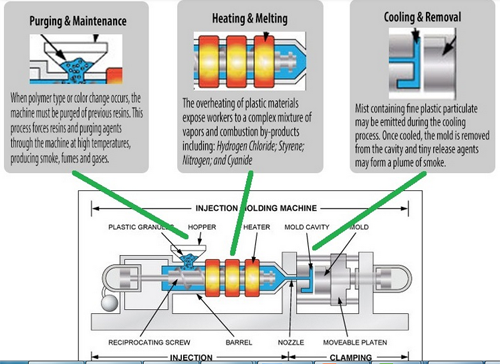

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q:What's the meaning of the connection between the injection machine and the manipulator?

- That is to say, the manipulator and the forming machine are interlocking with each other, such as the mold opening, the safety door, the full-automatic, etc. the forming machine gives a signal to the manipulator, and the other vice versa... Can refer to physical see, not difficult to understand, welcome to ask

- Q:How will the screw speed of injection molding machine be adjusted slowly?

- In the screw speed adjustment, from the lower speed start, gradually commissioning to higher speed, and then determine the screw speed.The working speed of the screw of the injection machine is unstable and is affected by the following factors:1, drive V belt wear seriously, slipping when working.2, V belt drive belt wheel center distance is too small, so that belt drive can not and belt pulley trapezoidal slope correct friction drive work.3. The temperature of the heating material in the barrel is low, and the material is not uniform, which leads to the screw rotation of the injection machine, the increase of the working load torque, and the instability of the screw speed of the injection molding machine.4, injection molding machine screw thrust bearing damage, etc..

- Q:How many grams of 200t injection molding machine?

- Heating part energy saving: heating part energy saving, mostly using electromagnetic heater energy saving, energy saving rate is about 30%-70% of old resistance ring.1. compared with the resistance heating, the electromagnetic heater has a layer of thermal insulation layer, and the heat energy utilization rate is increased.2. compared with the resistance heating, the electromagnetic heater acts directly on the tube heating, reducing the heat transfer and thermal energy loss.

- Q:Injection molding machine products have cloak how to solve?

- Or choose something less liquidIf it can not solve the need to start from the mold block, the mold is not high precision, then how to change the material is very resolved

- Q:Ready to open a small injection molding plantThere are only two machines at the moment, one 160T, one 250TProducts are note PA, PP, PU round (3, 4, 5 inches through)I would like to help you count, if 2 machines 24 hours boot, a month down, the output value of these 2 machines about how much? Thank you, the best way to calculate ~ ~!

- To say the first mock exam number, production cycle. Otherwise, no one will count, ask me questions after adding, and I'll try my best to answer youYou have to pay for the electricity, plus a grill. Mould temperature machine, if use PA material, electricity charge must be more, cycle is so long, install an electric appliance.

- Q:How to install filter screen for injection machine nozzle?

- There are special filter nozzle, used for recycling materials, can protect the mold and hot runner, with few manufacturers.

- Q:Injection molding machine rankings?

- Haida machine, A Well-Known Trademark in China, national Mianjian products, high-tech enterprise, Zhejiang famous brand, Zhejiang famous trademarks, China Plastic Machinery Industry Association executive director of the unit.

- Q:What does "120T 140T" mean in an injection machine?

- A, an abbreviation for ounce, is a unit used by the Hongkong industry to distinguish between injection molding machines. In this way, in the domestic commonly known as "T" (ton), "12" equivalent to "160T", the screw diameter of about 32 mm. In general, the injection molding machine of various specifications, there are several specifications of the screw, buyers can choose different screw size according to their uses, the screw diameter may be selected smaller, and the groove depth is also different with a shallow depth.

- Q:How to reset the EM-120 origin of the injection machine?

- 6, locking machine to machine hinge straight;7, repeat third steps;8, enter 1 at the default mode 1; move the cursor back to preset 1; appear as input Press confirm again;9, enter 2000 at the preset mode 2;10, repeat the lock die 3 to 4 times to the machine hinge straight, see the actual value of the lock more than how many; 2000 minus the remaining numberValue; enter preset 2;11, reset the high pressure die termination position and adjust the clamping force to the die.

- Q:What is the injection molding machine?

- An injection molding machine is a mechanical device that fills a plastic into plastic!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-900A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords