hot rolled stainless steel coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel coil

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Article | stainless steel coil |

Specification | 1m 1.219m 1.5m or as your requirement |

Surface | 2B NO.1 BA Hairline 4K 6K 8K No.3 No.4 |

Type | coil |

Thickness | 3-30 mm |

Brand | TISCO JISCO LISCO and so on |

Application | Foodstuff,gas,biology,metallurgy,electron,chemical,petroleum,boiler,nuclear energy, equipment fertilizeretc and so on |

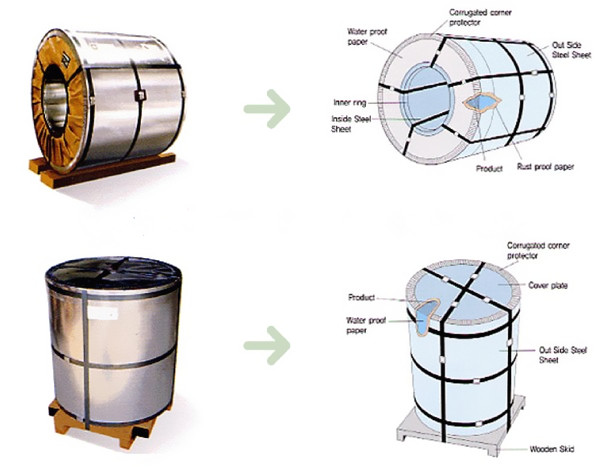

Parking | Waterproof paper, steel strip packed, wooden case,or as customers's requirement |

Payment | Small quantity (within total $20000.00) T/T at sight, 30% in advance , 70% after receiving the B/L Large quantity : L/C at sight |

container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

Delivery Time | 15 days after received the deposit of T/T or L/C |

Note | We can produce other standard as the customers’s requirement |

A series of pictures

- Q:What is the process of uncoiling steel coils?

- The process of uncoiling steel coils involves carefully unwinding the tightly wound steel coil using specialized equipment. This typically includes a decoiler or uncoiler machine that holds and releases the coil, allowing it to gradually unwind. The coil is typically fed through a set of rollers or guides to ensure a smooth and controlled unwinding process. As the coil unwinds, it can be further processed or used for various applications, such as cutting, stamping, or forming into different shapes.

- Q:ok I got a dpms ar 15 and all i have put though it is good brass 223 ammo but is it ok to shoot the old crappy steel cased wolf ammo out of it will it hurt its function or will it hurt it cosmetically?

- The Wolf ammo and the rest of its ilk also has steel bullet jackets, so it will wear your barrel faster than copper jacketed ammo. Plus you can't reload it. I've also seen a few manufacturers say not to use it as pressures may be erratic. I wouldn't buy it to shoot unless I was shooting it in someone else's rifle, I would buy it to stash though.

- Q:What are the different types of steel coil slitting knives?

- There are several different types of steel coil slitting knives, including circular slitting knives, straight slitting knives, and crush-cut slitting knives. These knives are used for precision cutting and slitting of steel coils into narrower strips or sheets. Circular slitting knives feature a circular shape with sharp edges, while straight slitting knives have a straight cutting edge. Crush-cut slitting knives have a unique design that allows them to crush and cut the material simultaneously. Each type of knife is used for specific applications and offers different advantages depending on the desired outcome.

- Q:Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- A full choke is not recommended for most steel shot. That gun was made before steel shot was popular and the barrel probably will not hold up to the hard steel shot. You have two options. Both will cost money. You can get the soft heavy shot and use that. Or you can buy a newer shotgun and use steel in it.

- Q:aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q:My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- Easy. okorder /

- Q:How are steel coils inspected for flatness using optical sensors?

- Steel coils are inspected for flatness using optical sensors by employing a system known as optical flatness measurement. This method involves the use of high-resolution cameras that capture images of the steel surface as it passes through the inspection line. Firstly, the steel coil is unwound and passed over a roller table. As it moves, the optical sensors are positioned above the coil to capture images at regular intervals. These sensors typically consist of a combination of laser line projectors and high-resolution cameras. The laser line projectors emit a thin, straight line of laser light across the width of the steel coil. This laser line acts as a reference plane for measuring the flatness of the steel surface. The high-resolution cameras then capture images of the laser line as it interacts with the steel coil. The captured images are then analyzed using advanced image processing algorithms. The algorithms analyze the deformation of the laser line on the steel surface and calculate the deviations from the flat reference plane. These deviations indicate any irregularities or variations in the flatness of the steel coil. The optical sensors can accurately detect even the slightest deviations in flatness, measuring them in micrometers or even smaller units. This enables manufacturers to identify and rectify any flatness issues in the steel coils before further processing or shipment. In addition to measuring flatness, optical sensors can also detect other surface defects such as waviness, scratches, or dents. By incorporating multiple cameras and laser line projectors from different angles, a comprehensive inspection of the steel coil's surface can be achieved. Overall, the use of optical sensors for inspecting steel coil flatness provides a fast, accurate, and non-contact method. By detecting and rectifying any flatness issues early in the production process, manufacturers can ensure the delivery of high-quality steel products to their customers.

- Q:I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- If you really want to do this, you should be getting some books on steel metallurgy rather than asking on Yahoo. ASM sells a Metallurgy for the non-metallurgist that would be a good introduction. Most university libraries will have the full ASM handbook that includes detailed information for different grades of steel (vol 1), heat treatment and surface hardening (vol 4), testing (vols 8-12), and casting (vol 15). A reference for continuous cooling transformation diagrams will also help in designing a heat treatment process. If you want to make something stronger than most commercial steels, you'll need to get into nanotechnology and unconventional steel processing methods like powder metallurgy. You can increase the strength of steel by about 1000% by reducing the grain size from 50 micron (typical for conventional processing methods) to 100 nm (achievable through high-energy ball milling). Though you'd also need to customize the chemistry to stabilize the grain size during the necessary thermal processing, I believe zirconium works well with iron.

- Q:What is the major disadvantage of hardened steel? Do you think this form of iron would be wear resistant and retain a sharpened edge?

- The major disadvantage of hardened steel is that it is very brittle unless it is tempered. Hardened steel would be wear resistant, and would hold an edge as long as you don't cut anything harder than a boiled egg - the impact of the knife on a cutting board would shatter it.

- Q:So I want to get my 3+ wood shafted with a dynamic gold shaft because i need a stiffer shaft but dont want to spend much on it.I've never swung a steel shafted wood, but I hear that it is more consistent that graphite....Plus, since the cost of steel is only $15 compared to the $65 graphite, not to mention installation charges.So yeah...... How good is steel for fairway woods?BTW, my swing speed is about 95 but i can amp it up to 110 (with control, that is)

- There are very few people who hit steel shafted fairway woods. Tiger Woods used to have a steel shafted 3 wood but went to graphite because it didn't feel right because of his driver. Go get custom fit for a shaft and see if a steel shaft is good to make sure because you don't want to turn aroung a get a graphite shaft anyway if the steel shaft doesn't work. Go with whatg works the first time so you don't put out more money later.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hot rolled stainless steel coil

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords