Best Quality For Hot Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

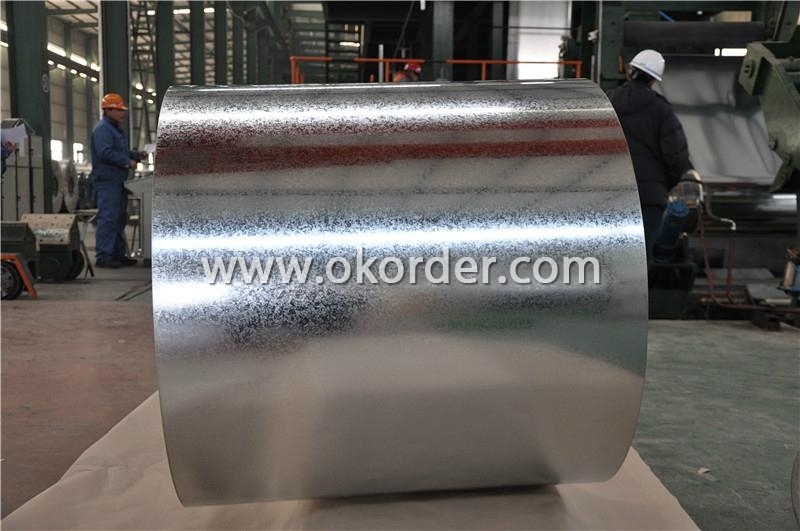

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil

1. Thickness: 0.15-1.2mm

2. Width: 800mm-1250mm

3. Zinc Coating: 70-180g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry, chromated, non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

|

Technical Data | |

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q:I personally don't believe the story of 8 guys who flew small planes can navigate passenger jets into buildings hundreds of miles away with that precision. It just doesn't make sense.I am wondering what the story surrounding the molten steel was, how could molten steel have been produced when fuel from the planes wasn't hot enough (it melts at 2850 degrees)?

- that's just it: there wasn't very much molten steel for the very reason you point out. Jet fuel burns at 800° to 1500°F. This is not hot enough to melt structural steel. However, engineers say that for the World Trade Center towers to collapse, their steel frames didn't need to melt, they just had to lose some of their structural strength. Steel will lose about half its strength at 1,200 degrees F. The steel will also become distorted when heat is not a uniform temperature. after the collapse, a LOT of folks took a look at the remains. the result was the conclusion that the fire caused the central core of the building to weaken. When the floors collapsed one on top of the other, the weight was too much for the weaked core to bear, causing the result we are all familiar with. hope this helps

- Q:What is the maximum weight capacity for a steel coil lifting device?

- The maximum weight capacity for a steel coil lifting device can vary depending on the specific design and model. However, these lifting devices are typically designed to handle heavy loads and can have weight capacities ranging from a few tons to over 100 tons. It is important to consult the manufacturer's specifications or guidelines to determine the exact maximum weight capacity for a particular steel coil lifting device.

- Q:How are steel coils used in the production of packaging materials?

- Steel coils are used in the production of packaging materials as they are processed and shaped into various forms, such as sheets or strips, which can be used to create durable and sturdy packaging products. These coils are often used to make packaging materials like cans, drums, and containers, providing strength, structural stability, and protection to the packaged goods during storage and transportation.

- Q:How are steel coils used in the production of metal buildings?

- Steel coils are used in the production of metal buildings as they are rolled into sheets and then formed into various structural components such as beams, columns, and roof panels. These coils allow for efficient mass production and provide a high-strength and durable material that ensures the structural integrity of the metal building.

- Q:I have a need to connect various stainless steel tubes and fitting together and was wondering how to do it. I know a TIG welder is an option but have heard rumors that there is a way to solder it in much the same way you affix copper pipe. Perhaps with higher heat and different flux. I need step by step and maybe suppliers of the materials. Thanks in advance and please I do not need the call a plumber answers as I've gotten in the past

- ss has to be either welded or brazed you can [solder ] it but it has to be a silver solder, and will not have any strength

- Q:How are steel coils priced?

- Steel coils are typically priced based on several factors including the current market demand and supply, the grade and quality of the steel, production and transportation costs, as well as any additional processing or customization requirements.

- Q:What are the different testing methods used for steel coils?

- There are several testing methods used for steel coils, including visual inspection, dimensional measurements, hardness testing, chemical composition analysis, and various non-destructive testing techniques such as ultrasonic testing, magnetic particle testing, and eddy current testing. These methods help ensure the quality and integrity of steel coils by detecting any defects, flaws, or deviations from the required specifications.

- Q:What are the different surface treatments for steel coils?

- Steel coils can undergo various surface treatments to achieve different outcomes and applications. Some commonly used treatments include: 1. Hot-dip galvanizing: Steel coils are immersed in molten zinc, which forms a protective layer on the surface. This treatment provides excellent corrosion resistance for outdoor use. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coils. It offers good corrosion resistance and is suitable for indoor applications. 3. Powder coating: Dry powder is applied to the surface and heated to form a durable coating. It provides excellent corrosion resistance and comes in different colors and finishes. 4. Paint coating: Steel coils can be coated with liquid paint, offering both corrosion resistance and aesthetic appeal. The thickness and finish can be customized according to the desired look and level of protection. 5. Phosphating: Steel coils are immersed in a phosphate solution, creating a thin layer that enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Steel coils are immersed in a solution containing chromium salts, providing excellent corrosion resistance and acting as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: A layer of zinc-nickel alloy is electroplated onto the steel coils, offering superior corrosion resistance compared to pure zinc plating and is suitable for demanding environments. These are just a few examples of the many available surface treatments for steel coils. The choice depends on factors such as application, desired corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider project needs and consult with experts to determine the most suitable treatment.

- Q:What are the benefits of using stainless steel coils?

- Using stainless steel coils in various applications offers multiple advantages. Firstly, stainless steel coils are renowned for their exceptional strength and durability, making them highly resistant to corrosion, rust, and stains. As a result, they can withstand harsh environmental conditions, both indoors and outdoors, ensuring their longevity and reducing the need for frequent replacements, ultimately saving costs in the long term. Furthermore, stainless steel coils provide excellent heat resistance, as they can endure high temperatures without warping or compromising their structural integrity. This makes them ideal for applications involving extreme heat or thermal cycling, such as industrial furnaces or heating systems. Another benefit of utilizing stainless steel coils lies in their versatility. Stainless steel is a highly adaptable material that can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. Consequently, stainless steel coils can meet specific requirements across different industries, including construction, automotive, aerospace, and household appliances. In addition to their physical properties, stainless steel coils are favored for their hygienic qualities. Being non-porous, stainless steel resists bacteria, mold, and other contaminants, making it an excellent choice for applications demanding strict cleanliness and hygiene standards, such as the food and beverage industry or medical equipment. Lastly, stainless steel coils are environmentally friendly. They can be fully recycled, melted down, and repurposed to create new products, reducing waste and conserving resources. This sustainability aspect makes stainless steel coils an eco-conscious choice for numerous industries. Overall, the benefits of utilizing stainless steel coils encompass their strength, durability, heat resistance, versatility, hygiene, and environmental friendliness. These qualities make stainless steel coils a reliable and cost-effective solution for a wide range of applications.

- Q:Hello... I'd like to know where I can find proof of this answer as well please. My own searching didn't come up with anything concrete.I'd like to know how much the ambient temperature inside of a hollow steel tube would rise by if the outside of that tube was exposed to an 1100 degree flame for a period of 3 seconds.If specifics help, they are something along the lines of 3.125 O.D. tube, 0.35 wall thickness. High grade steel, can't be more specific than that sorry.Thanks for any answers!

- I can asnswer this from practical experience. If the tube is sealed, temperature would rise approx. 25 deg F. If the tube were open the temperature would be less that a 10 deg F rise. The exact answer can be found in any book on thermodynamics.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality For Hot Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords