Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Light Steel Rail with High Quality 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Light Steel Rail with High Quality 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Product Advantages:

OKorder's Hot Rolled Light Steel Rail with High Quality 55Q are durable, strong, and with competitive price

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

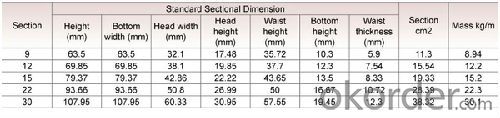

Product Specifications:

Manufacture: Hot rolled

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 25m, as per customer request

Packaging: Export packing, nude packing, bundled

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Sizes: 9kg-60kg

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4:What is the package

A4: Standard seaworthy packing or as customer required; all goods are packed in bundle with steel strips and shipped by break bulk vessel or container

Images:

.

- Q:Are steel rails affected by changes in ground settlement?

- Changes in ground settlement can have an impact on steel rails. Ground settlement occurs when the Earth's surface moves downward due to factors like soil consolidation, erosion, or the settling of loose materials. When this happens beneath railroad tracks, it can cause the steel rails to become misaligned. The settlement of the ground can result in the shifting or sinking of the rails, creating an uneven track surface. This can lead to various problems, including track misalignment, increased wear and tear on the rails, and the risk of derailments. It is vital for maintenance teams responsible for rail infrastructure to monitor and address any ground settlement issues to ensure the safety and efficiency of the railway network. To minimize the impact of ground settlement, different techniques can be used. One commonly employed approach is the use of ballast, which involves placing a layer of crushed stones or gravel beneath the tracks. The ballast helps distribute the load from the rails and provides stability, reducing the effects of settlement on the tracks. In addition, regular inspections and maintenance are crucial for promptly identifying and resolving settlement-related problems. Monitoring systems such as track geometry cars or continuous track monitoring systems can detect changes in rail alignment or settlement, enabling maintenance crews to take corrective actions promptly. In conclusion, changes in ground settlement can indeed affect steel rails. Regular monitoring, proper maintenance, and the use of appropriate infrastructure design and materials are essential to minimize the impact of settlement on railroad tracks and ensure the safe and reliable operation of trains.

- Q:How do steel rails compare to other materials in terms of cost?

- Steel rails are generally more cost-effective compared to other materials such as concrete or composite materials. The initial installation cost of steel rails is lower, and they also require less maintenance and repair, making them a more economical choice in the long run.

- Q:How do steel rails contribute to reducing track maintenance intervals?

- Steel rails contribute to reducing track maintenance intervals in several ways. Firstly, steel rails have high durability and strength, which allows them to withstand heavy loads and frequent train traffic without significant wear and tear. This reduces the need for frequent repairs or replacements of the tracks, thus extending the maintenance intervals. Additionally, steel rails have excellent resistance to corrosion, preventing rust and deterioration that could weaken the tracks and require more frequent maintenance. Furthermore, the smooth surface of steel rails reduces friction between the train wheels and the tracks, minimizing wear and tear on both components. This reduction in friction also improves the overall efficiency of train operations, reducing the need for frequent maintenance intervals. Overall, the use of steel rails provides a reliable and long-lasting infrastructure that minimizes maintenance requirements and enhances the overall efficiency and safety of railway systems.

- Q:Are steel rails used in ski resort tramways?

- No, steel rails are not typically used in ski resort tramways. Ski resort tramways, also known as chairlifts or gondolas, are usually supported by towers and cables rather than rails. The chairs or gondolas are attached to the cable and travel along the cable route, carrying skiers and snowboarders up and down the mountain. Steel rails are more commonly used in traditional railways and metro systems, where the train or tram runs on top of the rails.

- Q:What is the role of steel rails in reducing train maintenance costs?

- The role of steel rails in reducing train maintenance costs is significant. Steel rails provide a durable and smooth surface for train wheels to run on, minimizing wear and tear on both the wheels and the track itself. This reduces the need for frequent maintenance and repairs, ultimately lowering the overall maintenance costs for trains. Additionally, steel rails have high strength and resistance to deformation, ensuring the stability and safety of the track, which further contributes to minimizing maintenance expenses.

- Q:Can steel rails be used in extreme cold temperatures?

- Steel rails are capable of being utilized in extremely cold temperatures. The durability and strength of steel make it suitable for a variety of environments, including those with freezing temperatures. Railways all around the world frequently employ steel rails, even in regions with freezing temperatures. However, it is important to note that proper maintenance practices must be implemented to ensure the longevity and performance of the rails in extreme cold conditions. This may involve regular inspections, lubrication of the rails, and the prompt removal of any ice or snow accumulation. Furthermore, steel rails are often manufactured with specific alloys that enhance their resistance to cold temperatures, preventing them from cracking or becoming brittle. In summary, steel rails are designed to endure extreme weather conditions, including cold temperatures, and are a dependable choice for railways operating in such environments.

- Q:Can steel rails be used for urban transit systems?

- Yes, steel rails can be used for urban transit systems. Steel rails are commonly used in urban transit systems around the world due to their durability, strength, and ability to withstand heavy loads and constant use. They provide a stable and reliable track infrastructure that allows for smooth and efficient movement of trains or trams in urban areas.

- Q:What are the safety regulations for steel rail installation?

- The safety regulations for steel rail installation typically include ensuring proper alignment and spacing of the rails, securing the tracks to the sleepers or ties, conducting regular inspections and maintenance, implementing appropriate signaling and communication systems, and following specific procedures for welding or joining the rails. Additionally, safety measures may include providing adequate training and personal protective equipment for workers involved in the installation process and adhering to relevant local or national safety standards and guidelines.

- Q:How are steel rails maintained in urban areas?

- Steel rails in urban areas are maintained through a combination of regular inspections, cleaning, lubrication, and repairs. Inspections help identify any damage or wear, while cleaning removes debris and prevents rust. Lubrication helps reduce friction and wear, ensuring smooth operation. Additionally, any necessary repairs or replacements are carried out promptly to maintain the structural integrity and safety of the rails.

- Q:How are steel rails protected against extreme temperatures?

- Steel rails are protected against extreme temperatures through a process called thermal expansion and contraction. Steel has a high coefficient of thermal expansion, so it expands and contracts with temperature changes. To accommodate this, gaps are left between individual rail sections, allowing them to expand and contract without buckling or warping. Additionally, rail materials are carefully chosen to withstand temperature variations and reduce the risk of damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords