Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

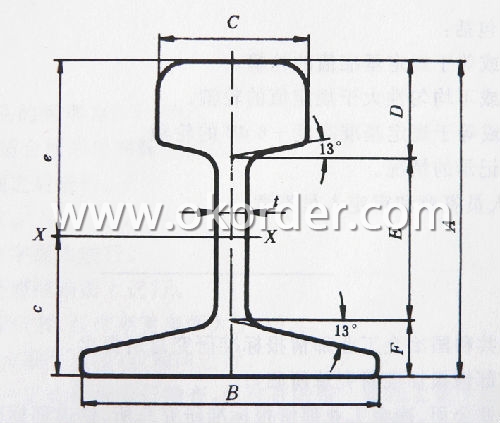

Specificaions of Steel Heavy Rail GB2585-81 with High Quality:

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C | Mn | S | P | Si | |

50Mn | 0.48—0.56 | 0.70—1.00 | ≤0.035 | ≤0.035 | 0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Steel Heavy Rail GB2585-81 with High Quality:

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Steel Heavy Rail GB2585-81 with High Quality:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Steel Heavy Rail GB2585-81 with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:What are the main advantages of using steel rails?

- The main advantages of using steel rails are their durability, strength, and resistance to wear and tear. Steel rails can withstand heavy loads and provide a stable and smooth surface for trains to travel on. Additionally, steel rails have a longer lifespan compared to other materials, reducing maintenance and replacement costs.

- Q:How do steel rails contribute to train stability during turns?

- Steel rails contribute to train stability during turns by providing a smooth and sturdy surface for the train's wheels to roll on. The rails guide and support the train's wheels, preventing them from derailing or slipping off the tracks. The steel material also offers excellent strength and durability, ensuring the rails can handle the lateral forces exerted on them during turns, maintaining the stability and safety of the train.

- Q:Can steel rails be curved for railroad tracks?

- Yes, steel rails can be curved for railroad tracks. The process involves bending the steel rails to the desired curvature using specialized equipment and techniques. This allows for efficient and safe navigation of trains around curves in the railroad network.

- Q:What is the impact of high-speed trains on steel rail tracks?

- High-speed trains have a significant impact on steel rail tracks. The high speeds at which these trains operate generate increased dynamic forces, resulting in higher wear and tear on the tracks. This leads to faster degradation of the steel rails, causing increased maintenance and replacement costs. Therefore, the impact of high-speed trains on steel rail tracks is substantial, necessitating regular inspections and upkeep to ensure safe and efficient operations.

- Q:How are steel rails protected from corrosion?

- Steel rails are protected from corrosion through a variety of methods and coatings. One of the most common techniques is applying a layer of zinc, known as galvanization, to the surface of the steel rails. This zinc layer acts as a sacrificial anode, meaning it corrodes instead of the steel, thus protecting the underlying metal. Another method is the application of a protective coating, such as epoxy or polyurethane, to the steel rails. These coatings create a barrier between the metal and the surrounding environment, preventing moisture and corrosive agents from coming into contact with the steel. Additionally, regular maintenance practices are crucial in preventing corrosion. This includes cleaning the rails regularly to remove any accumulated dirt, debris, or salt, which can accelerate corrosion. Inspections are also conducted to identify any signs of corrosion or damage and take necessary measures to address them promptly. Furthermore, proper drainage systems are implemented to prevent water or moisture from pooling around the rails, as prolonged exposure to moisture can lead to accelerated corrosion. In summary, steel rails are protected from corrosion through galvanization, protective coatings, regular maintenance practices, and proper drainage systems. These measures ensure the longevity and safety of the railway infrastructure.

- Q:What is heavy rail? What is light rail?

- The rail is divided into two kinds of heavy rail and light rail, and the rail specification is expressed by the nominal weight per meter. 3, heavy rail: nominal weight of more than 30 kg per meter rail, belong to heavy rail, heavy rail is divided into general rail and crane rail two.

- Q:What are the challenges of integrating steel rails in existing railway infrastructure?

- There are several challenges associated with integrating steel rails into existing railway infrastructure. First and foremost, ensuring compatibility between the new steel rails and the existing infrastructure is a primary concern. This involves aligning the dimensions, weight, and structural properties of the new rails with the existing track system to ensure proper functionality. Another challenge is the potential need for modifications or upgrades to the existing railway infrastructure. The condition and age of the infrastructure may require adjustments to accommodate the new steel rails. This could involve replacing sleepers, adjusting the ballast, or even reconfiguring the track layout in certain sections. In addition, careful planning and coordination are necessary to minimize disruptions to train services. This is especially important in busy or heavily trafficked rail networks, as delays or closures can significantly impact passenger or freight transportation. Timing the integration process to minimize disruptions, such as conducting work during off-peak hours or weekends, can help mitigate these challenges. Furthermore, the cost of integrating steel rails into existing infrastructure can be a significant obstacle. Procuring the steel rails, carrying out necessary modifications or upgrades, and ensuring compliance with safety regulations all come with expenses. Budget constraints may make it difficult to implement these changes, and securing funding for such projects can be a complex process. Lastly, the introduction of steel rails may require additional maintenance and inspection procedures to ensure their long-term performance. Steel rails have unique characteristics compared to other materials, like concrete or wood, and may require specialized maintenance practices or equipment. Providing training for staff and establishing proper maintenance protocols can be challenging but is essential to ensure the continued safety and reliability of the rail network. In conclusion, integrating steel rails into existing railway infrastructure presents challenges related to compatibility, modifications, disruptions, cost, and maintenance. However, with careful planning, coordination, and investment, these challenges can be overcome, leading to improved rail performance and efficiency.

- Q:Are steel rails prone to rail breakages?

- Yes, steel rails are prone to rail breakages, although the frequency of such incidents is relatively low. Various factors such as fatigue, wear and tear, and extreme weather conditions can contribute to rail breakages. However, proper maintenance and regular inspections help to minimize the risk and ensure the safety and reliability of the rail network.

- Q:What are the different types of rail profiles used in steel rails?

- There are several types of rail profiles used in steel rails, including the flat-bottomed rail (FB), the grooved rail (GR), the bullhead rail (BH), and the vignole rail (V). Each profile has its own specific design and usage, catering to different railway systems and requirements.

- Q:How are steel rails used in railway depots and maintenance yards?

- Steel rails are used in railway depots and maintenance yards to provide a sturdy and reliable track system for the movement of trains. They serve as the foundation on which the trains run, ensuring smooth and safe transportation. These rails are carefully laid out and maintained to withstand heavy loads and constant use, allowing for efficient operations and the seamless movement of trains within the depot or maintenance yard.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches