Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Light Rail

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

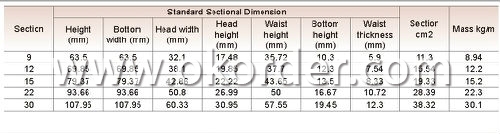

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| ||

Q235 |

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usages of Light Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Light Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:Can steel rails be used in areas with high electromagnetic interference?

- Yes, steel rails can be used in areas with high electromagnetic interference. Steel is a highly conductive material that can effectively dissipate electromagnetic interference (EMI) and provide a stable electrical grounding. Additionally, steel rail tracks are often installed with proper grounding systems to minimize the impact of EMI. However, it is important to note that certain precautions should be taken to ensure minimal interference, such as proper shielding of electrical equipment and cables, use of surge protection devices, and adherence to best practices for EMI mitigation.

- Q:Are steel rails suitable for high-speed train operations?

- Steel rails are indeed suitable for high-speed train operations. They have been utilized in railway systems worldwide for many years, including those specifically designed for high-speed trains. Steel is a robust and enduring material that is capable of withstanding the immense pressures and fast speeds of modern trains. Furthermore, steel rails possess exceptional track stability and are capable of enduring extreme weather conditions, thus rendering them suitable for high-speed train operations in various environments. Additionally, steel rails offer a smooth and dependable surface for trains to traverse, resulting in reduced vibrations and ensuring a comfortable journey for passengers. All in all, steel rails have demonstrated themselves to be a dependable and efficient choice for high-speed train operations.

- Q:How do steel rails handle heavy freight trains?

- Steel rails are specifically designed to handle heavy freight trains by providing a strong and durable track system. The high tensile strength of steel allows the rails to withstand the weight and pressure exerted by the heavy freight trains, ensuring stability and safety for the trains and their cargo. Additionally, steel rails have a smooth surface which reduces friction, allowing trains to travel efficiently and smoothly, even when carrying heavy loads.

- Q:How do steel rails resist corrosion?

- Steel rails resist corrosion due to the presence of a protective oxide layer on their surface, which forms naturally when exposed to oxygen in the air. Additionally, the rails are often coated with a layer of paint or a protective coating that acts as a barrier against moisture and other corrosive elements. Regular maintenance, such as periodic cleaning and repainting, also helps to prevent and control corrosion.

- Q:How are steel rails protected against track settlement?

- Steel rails are protected against track settlement through various methods. One of the most common methods is the use of ballast, which is a layer of crushed stones or gravel that is laid beneath and around the rails. The ballast provides stability and helps distribute the weight of the trains evenly, preventing excessive settlement. Additionally, the rails are designed to be rigid and durable, with proper spacing and alignment. This ensures that the weight of the trains is evenly distributed along the length of the rails, reducing the risk of settlement. The rails are also regularly inspected and maintained to identify any signs of settlement or deformation. In some cases, engineers may use techniques such as under-sleeper pads or resilient fasteners to further protect against settlement. Under-sleeper pads are rubber or polyurethane pads placed between the rail and the sleeper, which help absorb vibrations and reduce the impact of settlement. Resilient fasteners, on the other hand, are designed to allow some movement of the rail, compensating for settlement and reducing stress on the track structure. Overall, a combination of proper design, regular maintenance, and the use of ballast, under-sleeper pads, and resilient fasteners help protect steel rails against track settlement. These measures ensure the safety and stability of the tracks, minimizing the risk of derailments and ensuring smooth and efficient rail operations.

- Q:How do steel rails contribute to the efficiency of train operations?

- Steel rails contribute to the efficiency of train operations in several ways. Firstly, steel rails provide a smooth and stable surface for trains to travel on, reducing friction and allowing trains to move more efficiently. This leads to faster speeds and reduced energy consumption. Additionally, steel rails are durable and can withstand heavy loads, ensuring the safe and reliable movement of trains. Moreover, the precise alignment of steel rails enables trains to maintain their direction, reducing the chances of derailment and improving overall operational efficiency.

- Q:Can steel rails withstand heavy loads?

- Yes, steel rails are designed to withstand heavy loads. Steel is known for its high strength and durability, making it an ideal material for railway tracks. It can handle the weight of heavy trains and distribute the load evenly, ensuring safe and efficient transportation.

- Q:Are steel rails prone to cracking?

- Yes, steel rails are prone to cracking due to various factors such as stress, fatigue, and wear. Regular maintenance and inspections are necessary to detect and address any cracks to ensure the safety and integrity of the rail system.

- Q:What are the standards for steel rail manufacturing?

- The manufacturing of steel rails requires adherence to specific guidelines and specifications to ensure the production of high-quality and dependable rails for various applications, primarily in the railway sector. These standards are established and maintained by organizations such as ASTM, ISO, and CEN. Key aspects of steel rail manufacturing standards include: 1. Chemical Composition: The chemical composition of steel rails must meet specific requirements that determine their strength, durability, and resistance to wear and tear. These requirements typically include limits on the percentage of elements such as carbon, manganese, silicon, phosphorus, sulfur, and other trace elements. 2. Physical Properties: Steel rails must possess particular physical properties, including tensile strength, yield strength, elongation, and hardness. These properties ensure that the rails can endure the heavy loads and stresses experienced in railway operations without deformation or failure. 3. Dimensions and Geometry: Steel rails must adhere to strict dimensional and geometric tolerances to ensure compatibility and proper alignment with rail fastening systems, switches, and other components of railway infrastructure. These standards specify critical dimensions such as rail length, weight per unit length, head width, web thickness, flange height, and others. 4. Surface Quality: Steel rails must have a smooth and defect-free surface to minimize wear and decrease the risk of derailments. Surface quality standards establish limits on the presence of surface imperfections such as cracks, pits, laminations, and other irregularities. 5. Heat Treatment: Steel rails often undergo heat treatment processes like controlled cooling, quenching, and tempering to enhance their strength, toughness, and resistance to fatigue. Heat treatment standards define specific temperature ranges, holding times, and cooling rates required to achieve the desired material properties. 6. Testing and Inspection: Various non-destructive and destructive tests are conducted to assess the quality and integrity of steel rails. These tests include ultrasonic testing, magnetic particle inspection, hardness testing, and chemical analysis. Testing and inspection standards outline the procedures, acceptance criteria, and sampling plans to ensure consistent quality control throughout the manufacturing process. Compliance with these standards is essential for steel rail manufacturers to produce rails that meet the safety, reliability, and performance requirements of the railway industry. Adhering to these standards ensures that steel rails can withstand the demanding operational conditions of railways and contribute to the efficient and safe transportation of goods and passengers.

- Q:What are the different types of rail fastening systems used with steel rails?

- There are several types of rail fastening systems used with steel rails, including the Pandrol clip, the Vossloh fastening system, the Nabla system, the KPO clamp system, and the E-Clip system. Each of these systems has its own unique design and advantages, but they all serve the purpose of securely fastening the steel rails to the railway sleepers or ties.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords