Galvanized Steel Products of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

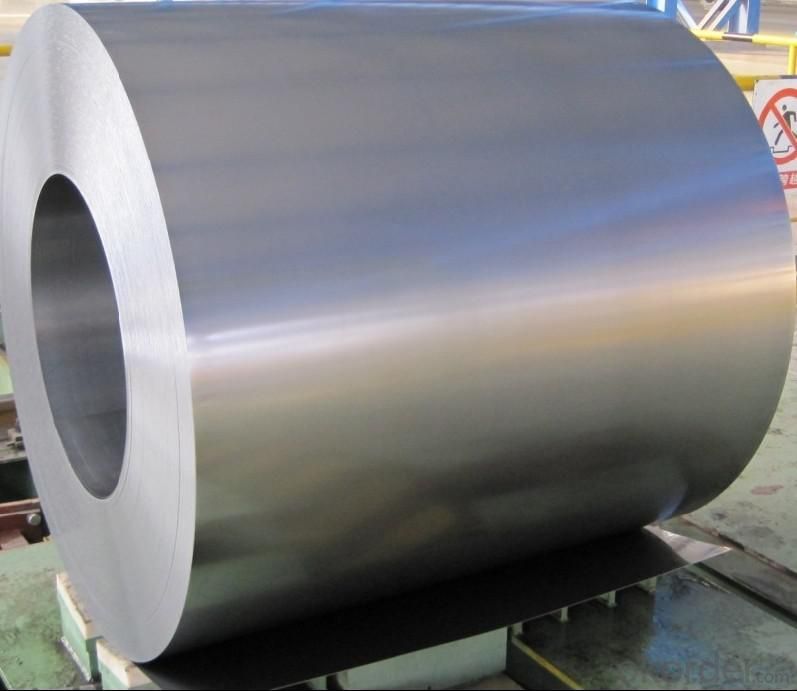

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

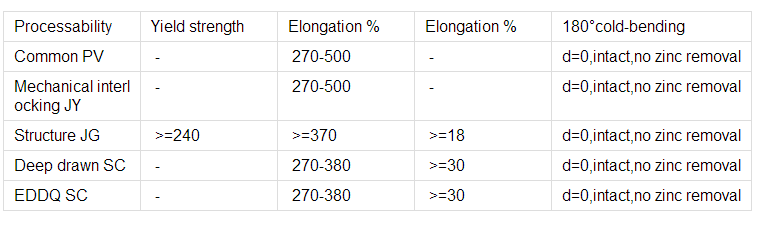

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils vary depending on factors such as the specific type of steel, the intended use, and industry standards. Generally, steel coils can range in width from a few inches to several feet, with thicknesses typically ranging from a fraction of an inch to several millimeters. The inner diameter of a steel coil can also vary, with common sizes being 20 inches and 24 inches. Ultimately, the dimensions of steel coils are determined by the specific needs and requirements of the end user.

- Q: My daughter wants a pair of steel toe cap boots for around the horses but wants them warm, so ideally fur lined etc. Does anybody know where I could purchase them as everywhere I look its only one or the other, cant get steel with fur lining. Very frustrating. I live in the uk. Many thanks.

- The steel toe cap wishes to be equipped for the duration of manufacture for the boots to arrive the desired standards. It could be nice if you looked at one of the PPE sites and see if you will see a pair that you may dye or paint.

- Q: What are the challenges in coil slitting for thin gauge materials?

- Coil slitting for thin gauge materials comes with its own set of challenges that need to be addressed for a successful operation. One major challenge is the handling and stability of the thin gauge material. The thinner the material, the more prone it is to deformation, wrinkling, or even tearing during the slitting process. This requires careful attention to the handling equipment and techniques to ensure proper tension and support throughout the slitting operation. Another challenge is maintaining consistent and precise slitting widths. Thin gauge materials are often used in applications where accuracy is crucial, such as in electronic components or automotive parts. Any variation in slitting width can lead to functional defects or assembly problems. Achieving precise slitting widths in thin gauge materials requires high-quality slitting knives, well-maintained slitting machinery, and accurate tension control systems. Additionally, thin gauge materials are more susceptible to surface defects, such as scratches or burrs, during the slitting process. These defects can affect the material's appearance, performance, or even its safety. Proper selection of slitting knives and regular maintenance of the slitting machinery are essential to minimize the occurrence of surface defects. Furthermore, thin gauge materials often have a higher yield strength, meaning they are more resistant to deformation. This poses a challenge when it comes to achieving clean and straight edges during the slitting process. Special considerations need to be taken to ensure that the slitting knives are sharp and properly aligned to achieve clean cuts without introducing any edge defects. Lastly, thin gauge materials are generally more sensitive to external factors such as temperature, humidity, or static electricity. These factors can affect the material's dimensional stability, leading to variations in slitting width or other quality issues. Consequently, it is important to establish suitable environmental conditions and implement proper anti-static measures to minimize the impact of these factors. In summary, the challenges in coil slitting for thin gauge materials revolve around handling and stability, maintaining precise slitting widths, minimizing surface defects, achieving clean and straight edges, and mitigating the impact of external factors. Overcoming these challenges requires a combination of appropriate equipment, techniques, and operational controls to ensure high-quality slitting results.

- Q: How are steel coils used in the production of bridges and infrastructure?

- Steel coils are used in the production of bridges and infrastructure as they are rolled into different shapes and sizes to form the structural components. These coils are then used to create beams, girders, and columns, providing strength and support to the structures. The flexibility and durability of steel allow for the construction of bridges and infrastructure that can withstand heavy loads, extreme weather conditions, and long-term use.

- Q: How are steel coils inspected for width using laser measurement?

- Steel coils are inspected for width using laser measurement by placing a laser sensor on one side of the coil and a reflective target on the other side. The laser beam is emitted towards the target, and the reflected beam is analyzed by the sensor. Based on the time it takes for the beam to travel back and the angle of the beam, the width of the steel coil can be accurately measured.

- Q: What are the factors that determine the price of steel coils?

- The factors that determine the price of steel coils include the current demand and supply levels in the market, the cost of raw materials and energy, the production and labor costs, transportation and logistics expenses, market competition, government policies and regulations, as well as currency exchange rates.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- It would actually cost you more to reload steel.

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Carbon steels are alloys. This is evident in the carbon-iron phase diagram:

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- Stainless steel is more corrosion resistant than steel and titanium is more corrosion resitant and lighter. However, titanium is more prone to picking up (scratches caused by normal tools creating scratches and leading to stress fractures). The Lockheed Blackbird had to have tools treated lithium grease (i could be wrong) to prevent this. I'd stick with stainless steel as i think any titanium exhaust you can buy will be a titanium composite due to its cost

- Q: How are steel coils packaged for shipping?

- Steel coils are typically packaged for shipping by being tightly wound and secured with steel strapping or bands. They are then placed onto pallets or into crates to protect them during transportation. Additionally, wooden or metal dunnage is often used to separate and stabilize the coils, ensuring they remain intact and in proper condition throughout the shipping process.

Send your message to us

Galvanized Steel Products of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords